Ultrasonic field non-contact visualization method for nondestructive inspection and device thereof

A non-destructive flaw detection and ultrasonic field technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves. It can solve the problems of high use and maintenance costs, expensive systems, complex and large systems, and improve reliability, efficiency, bandwidth and sensitivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

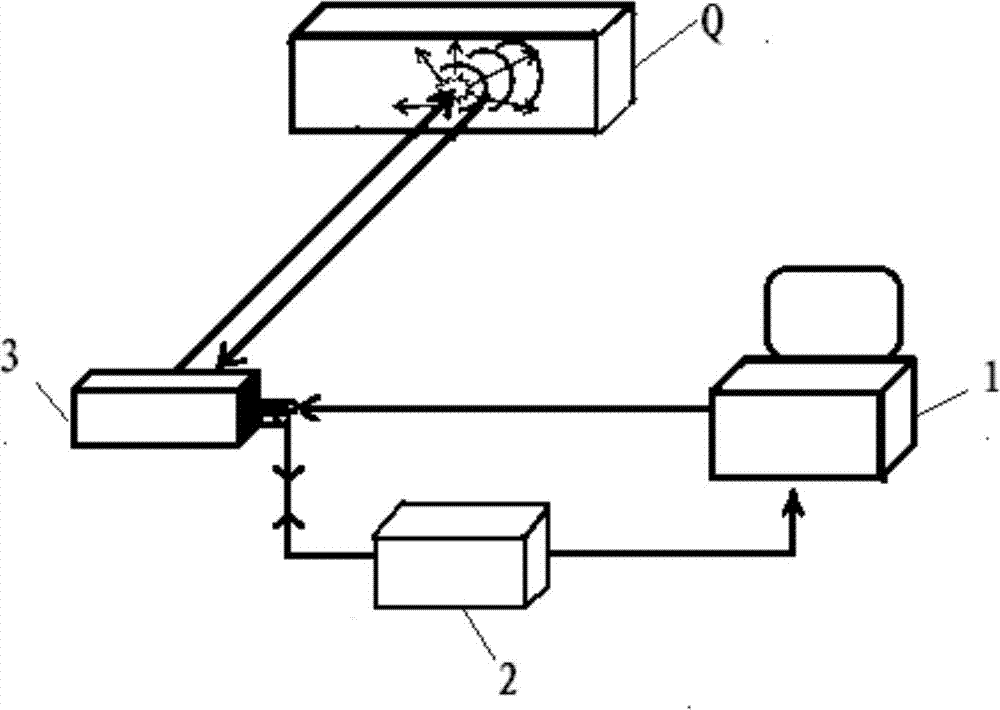

[0030] Embodiment: This example is the detection of surface defects on a thin aluminum plate with a thickness of 0.2 mm. The specific detection steps are:

[0031] (1) Place the thin aluminum plate in the effective area that the galvanometer scanning head can scan;

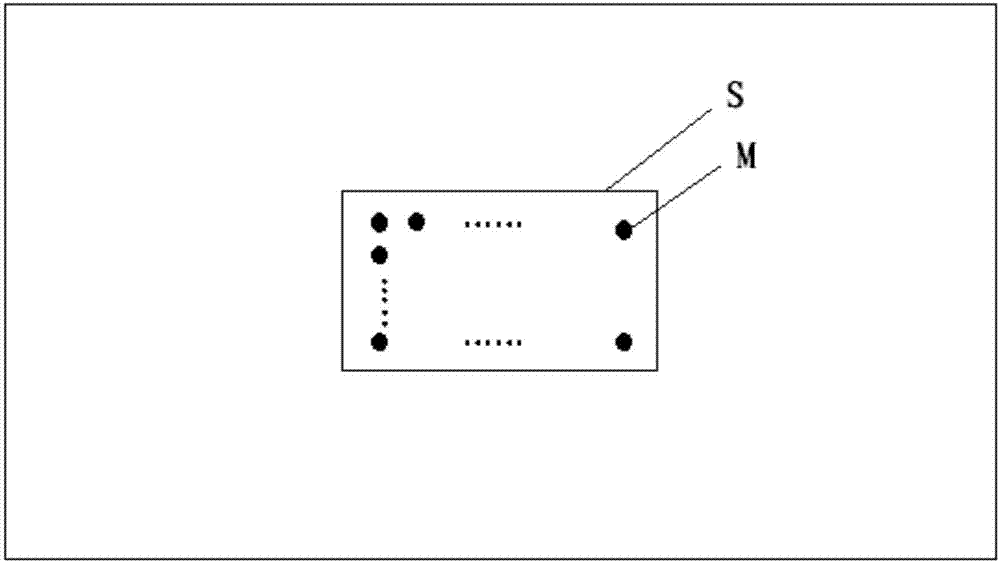

[0032] (2) Determine the detection area S of the thin aluminum plate through the red light indication of the galvanometer scanning head, and establish the detection area S as a model represented by the dot matrix M crossed by rows and columns through the computer, and then according to the detection requirements, through the sound field in the computer The visualization software sets the number of rows and columns of the lattice M to obtain sufficient spatial resolution, such as figure 2 shown;

[0033] (3) Select a certain point on the thin aluminum plate as the receiving point P for the laser interferometer to receive the ultrasonic sound signal;

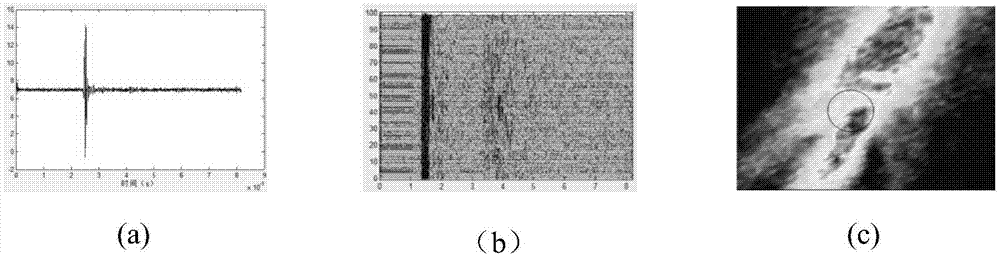

[0034] (4) Starting from a certain point in the detection are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com