Hard coat film, method for producing hard coat film, antireflection film, polarizing plate, and image display device

A hard coating film and hard coating technology, applied in chemical instruments and methods, coatings, transportation and packaging, etc., can solve the problems of lower rigidity of liquid crystal panels and easy warping of structural upper panels, and achieve low moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

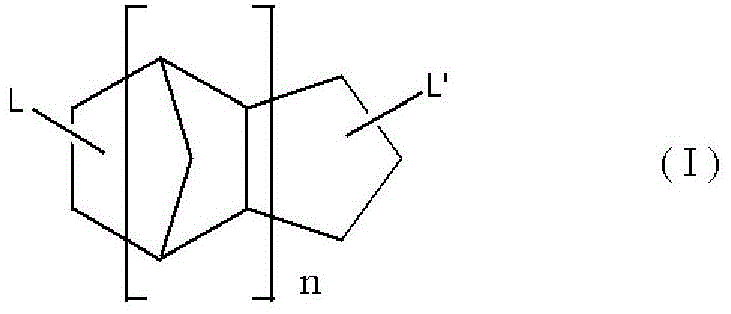

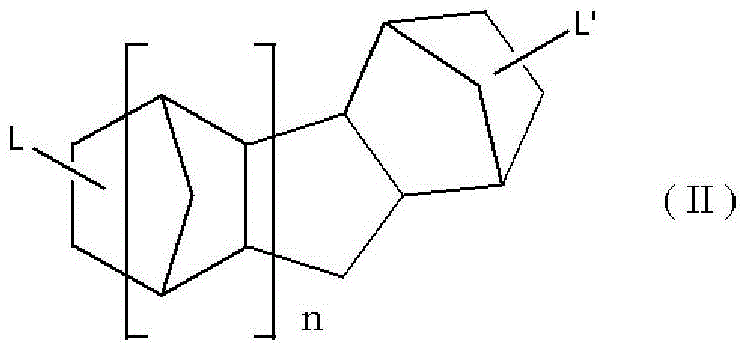

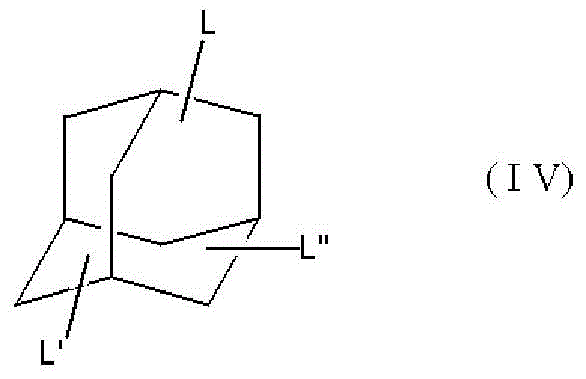

[0368] Hereinafter, an Example and a comparative example are given and the characteristics of this invention are demonstrated more concretely. Materials, usage-amounts, ratios, processing contents, processing procedures, and the like shown in the following examples can be appropriately changed unless departing from the gist of the present invention. Therefore, the scope of the present invention is not limitedly interpreted by the specific examples shown below. Among them, unless otherwise specified, "parts" and "%" are mass standards. A compound having a cyclic aliphatic hydrocarbon group and three or more ethylenically unsaturated double bond groups in the molecule used in the present invention was synthesized as follows. Compounds having a cycloaliphatic hydrocarbon group and three or more ethylenically unsaturated double bond groups in the molecule used in this example can also be synthesized by the same method.

[0369] (Synthesis of Compound A-2)

[0370] Into a reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com