Ultra-low volume liquid containing picoxystrobin and morpholine bactericide and application thereof

A technology of ultra-low-volume liquid agent and picoxystrobin, which is applied in the field of pesticides, can solve the problems of good solubility of the original drug, no ultra-low-volume liquid agent, and few ultra-low-volume liquid agents, and achieve good control effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

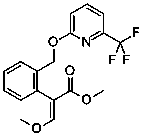

Image

Examples

Embodiment 1

[0032] Preparation of 16% picoxystrobin · dimethomorph ultra-low volume liquid

[0033]Weigh 0.5kg picoxystrobin, 15.0kg dimethomorph, 3.0kg fatty alcohol polyoxyethylene ether, 6.0kg alkylphenol polyoxyethylene ether, 5.0kg N,N-dimethylformamide, 30.0kg oil Acetate methyl ester, 40.5kg diesel oil, standby.

[0034] Put N, N-dimethylformamide into the reaction kettle, and stir the solvent, and at the same time, add boscalid, dimethomorph, boscalid, enoyl After the morpholine is completely dissolved, add co-solvents and additives into the reaction kettle and continue to stir for 15-60 minutes to obtain a uniform and transparent oily product.

Embodiment 2

[0036] Preparation of 12% picoxystrobin · dimethomorph ultra-low volume liquid

[0037] Weigh 10.0kg picoxystrobin, 2.0kg dimethomorph, 3.0kg calcium alkylbenzene sulfonate, 4.0kg alkylphenol polyoxyethylene ether, 20.0kg sulfolane, 30.0kg second-line oil, 31kg cottonseed oil, set aside .

[0038] Put sulfolane into the reaction kettle, and stir the solvent. At the same time, add boscalid and dimethomorph to the reaction kettle under stirring conditions. After the boscalid and dimethomorph are completely dissolved, add Add co-solvents and additives into the reaction kettle, and continue to stir for 15-60 minutes to obtain a uniform and transparent oily product.

Embodiment 3

[0040] Preparation of 8% picoxystrobin · dimethomorph ultra-low volume liquid

[0041] Weigh respectively 5.0kg picoxystrobin, 3.0kg dimethomorph, 0.5kg phenethylphenol polyoxyethylene ether, 0.5kg alkylphenol polyoxyethylene ether, 35.0kg N-methylpyrrolidone, 30.0kg styrene-butadiene, 26kg palm oil, spare.

[0042] Put N-methylpyrrolidone into the reaction kettle, and stir the solvent. At the same time, under stirring conditions, add boscalid and dimethomorph into the reaction kettle, and wait until the boscalid and dimethomorph are completely dissolved Finally, add co-solvent and additives into the reaction kettle, and continue to stir for 15-60 minutes to obtain a uniform and transparent oily product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com