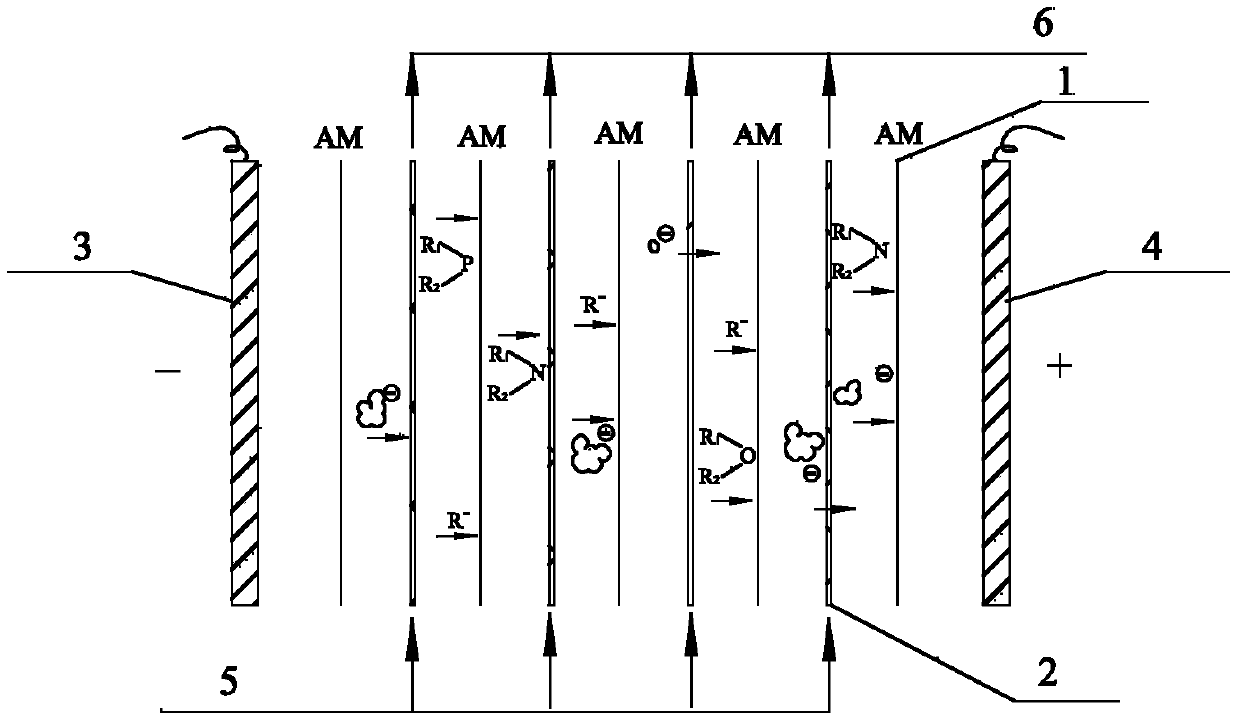

Method for protecting electric filter and removing electronegative colloids and particles in brine wastewater by electrodialysis

A technology of electric filter and saline wastewater, applied in electrodialysis, separation method, separation of dispersed particles, etc., can solve unspecified problems, reduce pollution degree, high selectivity and adsorption rate, and be beneficial to environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

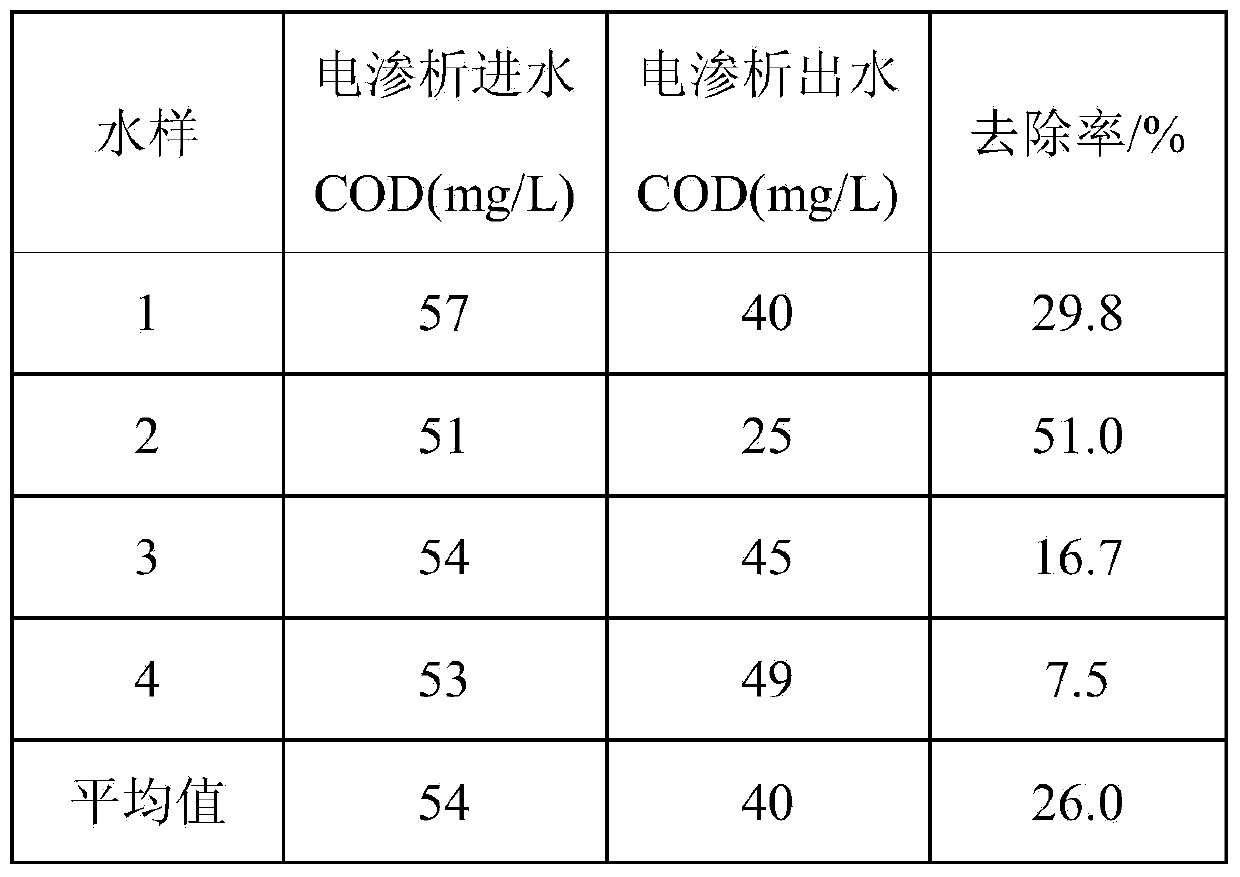

specific Embodiment 1

[0051] The circulating water sewage in the petrochemical industry is discharged after pretreatment such as hardening and turbidity removal, and is lifted by a pump to enter the electric filter of the present invention for continuous operation. The flow rate is adjusted by the flow meter, and the COD removal effect is controlled by adjusting the voltage and current. The water flow rate of the electric filter is 1m 3 / h, the applied voltage is 30V, the displayed current is 8A, and the sample is tested every 1 hour. The water quality indicators before and after treatment are shown in Table 1. It can be seen from the results in Table 1 that the COD content in the water was significantly reduced after being treated by the electric filter, with an average removal rate of 26% and a maximum of 51.0%.

[0052] Table 1 COD situation after electric filter treatment

[0053]

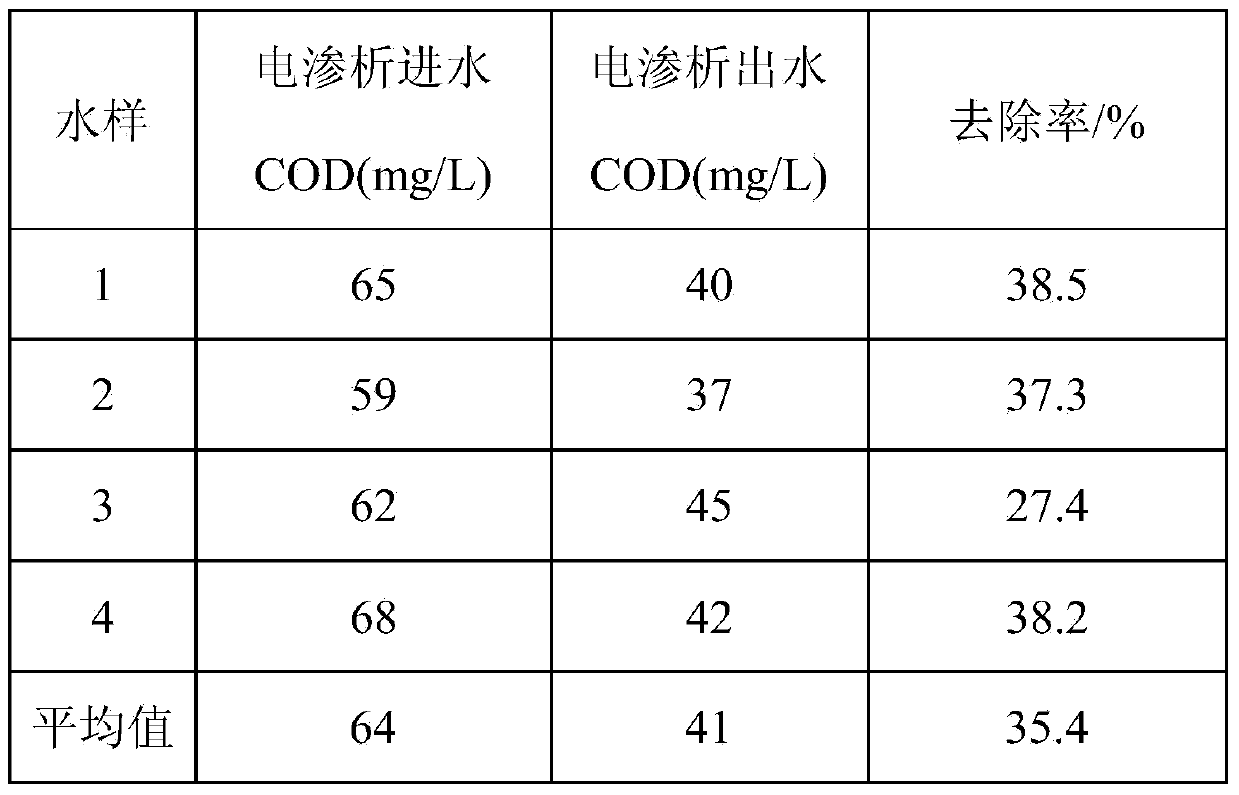

specific Embodiment 2

[0054] The circulating water and sewage of coal chemical coking enterprises are pretreated by hardening and turbidity removal, and then the water is lifted by a booster pump and enters the electric filter of the present invention for continuous operation. The flow rate is adjusted by the flow meter, and the COD removal effect is controlled by adjusting the voltage and current. The water flow rate of the electric filter is 1m 3 / h, the applied voltage is 35V, the displayed current is 10A, and the sample is tested every 1 hour. The water quality indicators before and after treatment are shown in Table 2. It can be seen from the results in Table 2 that the COD content in the water was significantly reduced after being treated by the electric filter, with an average removal rate of 35.4% and a maximum of 38.5%.

[0055] Table 2 COD situation after treatment by electric filter

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com