P-MBR biochemical treatment system and process

A biochemical treatment and process technology, applied in the field of P-MBR biochemical treatment system and process, can solve the problems of increased operating costs, loss of activated carbon, and inability to meet treatment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The invention provides a new biochemical treatment system and process, wherein the P-MBR biochemical treatment system and process combining biological activated carbon PAC process and membrane-biological reaction MBR process are adopted.

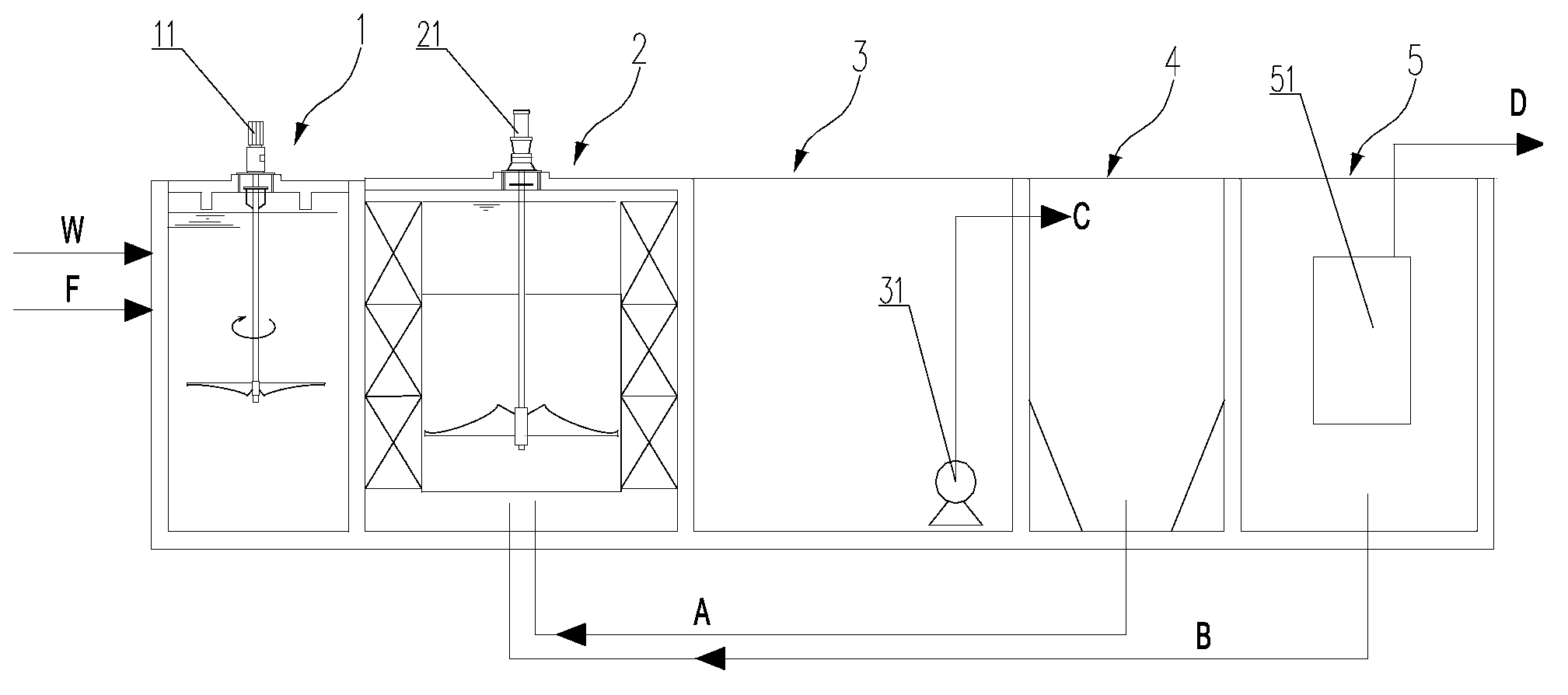

[0011] Such as figure 1 As shown, the PMBR biochemical treatment system of the present invention has mixing zone 1, adsorption flocculation zone 2, biochemical reaction zone 3, settling zone 4 and membrane filtration zone 5, wherein mixed adsorption zone 1 is used for entering waste water and adding new filling additives, and the waste water to be treated and the newly added active additives are separated by pipelines W and F (such as figure 1 Arrow) into the mixing zone 1 and initially mixed in the mixing zone 1. Adsorption and flocculation zone 2 is used to accommodate the mixed wastewater in the mixing zone and leave it for a period of time so that harmful substances in the wastewater can fully combine with active fillers to produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com