High-strength polypropylene anti-bacterial plastic

A technology of antibacterial plastics and polypropylene, applied in the field of plastics, can solve problems such as easy contamination, health hazards, and breeding of various microorganisms, and achieve high strength and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

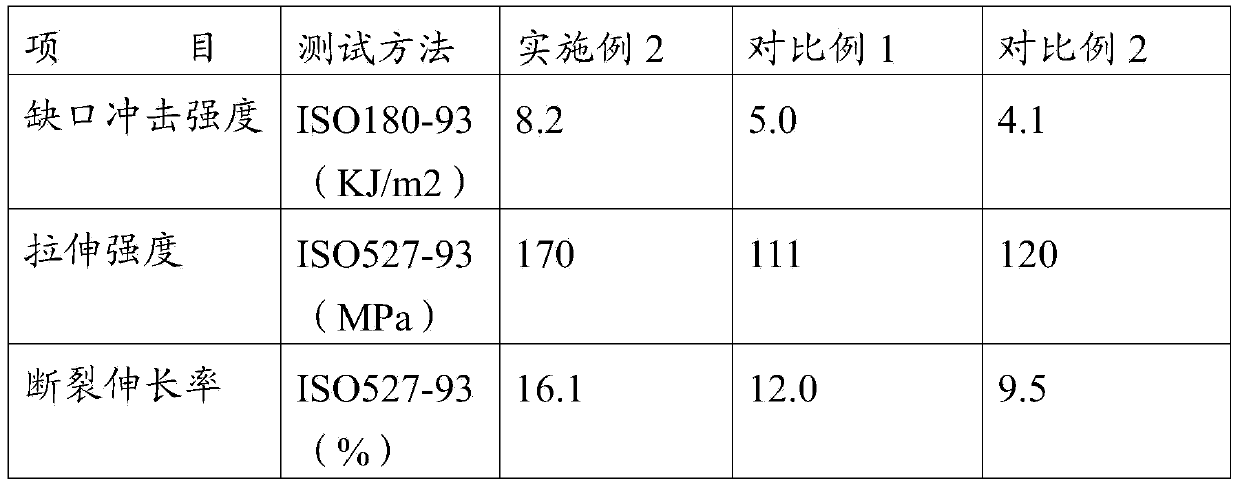

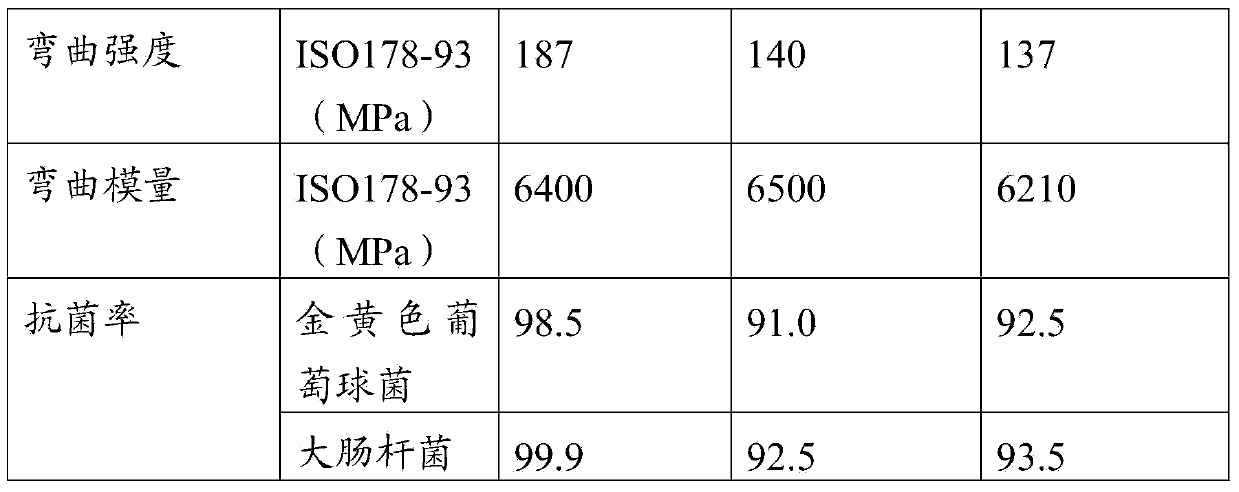

Examples

Embodiment 1

[0012] Weighing: 8 kg of chitosan, 15 kg of nano titanium dioxide, 15 kg of nano zeolite, and 8 kg of polyhexamethylene guanidine propionate. Stir and mix evenly, and the composite antibacterial agent is prepared.

[0013] An antioxidant is prepared by mixing 2 kg of 2,6-di-tert-butyl-4-methylphenol and 1 kg of trinonylphenyl phosphite.

Embodiment 2

[0015] Weigh the following raw materials according to the following weights:

[0016] 1 kilogram of antibacterial agent prepared in embodiment 1,

[0017] 0.6 kilograms of antioxidant prepared in embodiment 1,

[0018] Polypropylene 100 kg,

[0019] High-density polyethylene 15 kg,

[0020] Low-density polyethylene 15 kg,

[0021] 0.6 kg of polypropylene grafted maleic anhydride,

[0022] 0.5 kg of stearic acid,

[0023] Fiberglass 10 kg.

[0024] The above weighed raw materials were stirred in a high-speed mixer at 1200 rpm for 5 minutes, and released after being uniform. Put the uniformly mixed material into a twin-screw extruder with a length-to-diameter ratio (L / D) of 40. The processing temperature of the twin-screw extruder: the temperature in the first zone is 175°C, the temperature in the second zone is 185°C, and the temperature in the third zone is 200°C, the temperature in the fourth zone is 210°C, the temperature in the fifth zone is 215°C, the temperature in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com