Multifunctional coating additive, multifunctional coating and preparation method thereof

A coating additive and multi-functional technology, applied in the preparation of multi-functional coatings and multi-functional coatings, in the field of multi-functional coating additives, can solve problems such as troublesome operation and unsatisfactory effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 prepares multifunctional coating additive V

[0034] The camphor added in the multifunctional coating additive V is synthetic camphor, the solvent is ethylene glycol monobutyl ether, and the catalyst is dibutyltin dilaurate. The weight ratio of each component is:

[0035] Synthetic Camphor 40

[0036] Ethylene glycol monobutyl ether 59

[0037] Dibutyltin dilaurate 1 25

[0038] 200g of synthetic camphor and 5g of dibutyltin dilaurate were added to 295g of ethylene glycol monobutyl ether, and stirred to obtain multifunctional coating additive V. The appearance of Multifunctional Coating Auxiliary V is a slightly turbid light yellow solution.

Embodiment 2

[0039] Embodiment 2 prepares multifunctional coating additive W

[0040] The camphor added in the multifunctional coating additive W is natural camphor, the solvent is ethylene glycol monobutyl ether, and the catalyst is cobalt naphthenate. The weight ratio of each component is:

[0041] Natural Camphor 60

[0042] Ethylene glycol monobutyl ether 35

[0043] Cobalt naphthenate 5

[0044] 300g of natural camphor and 25g of dibutyltin dilaurate were added to 175g of ethylene glycol monobutyl ether respectively, and stirred to obtain multifunctional coating additive W. The appearance of the multifunctional coating additive W is a dark brown solution.

[0045] In some other embodiments, the weight ratio of camphor, solvent and catalyst can also be 50:47:3 or 45:52:3.

Embodiment 3

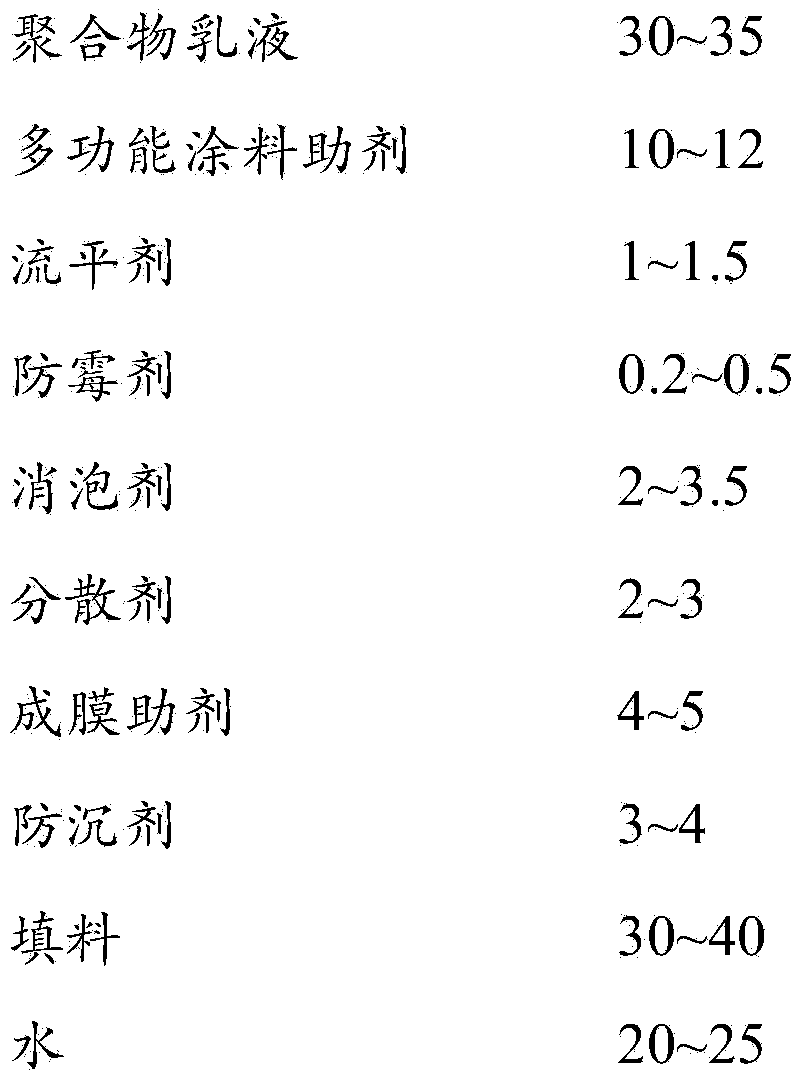

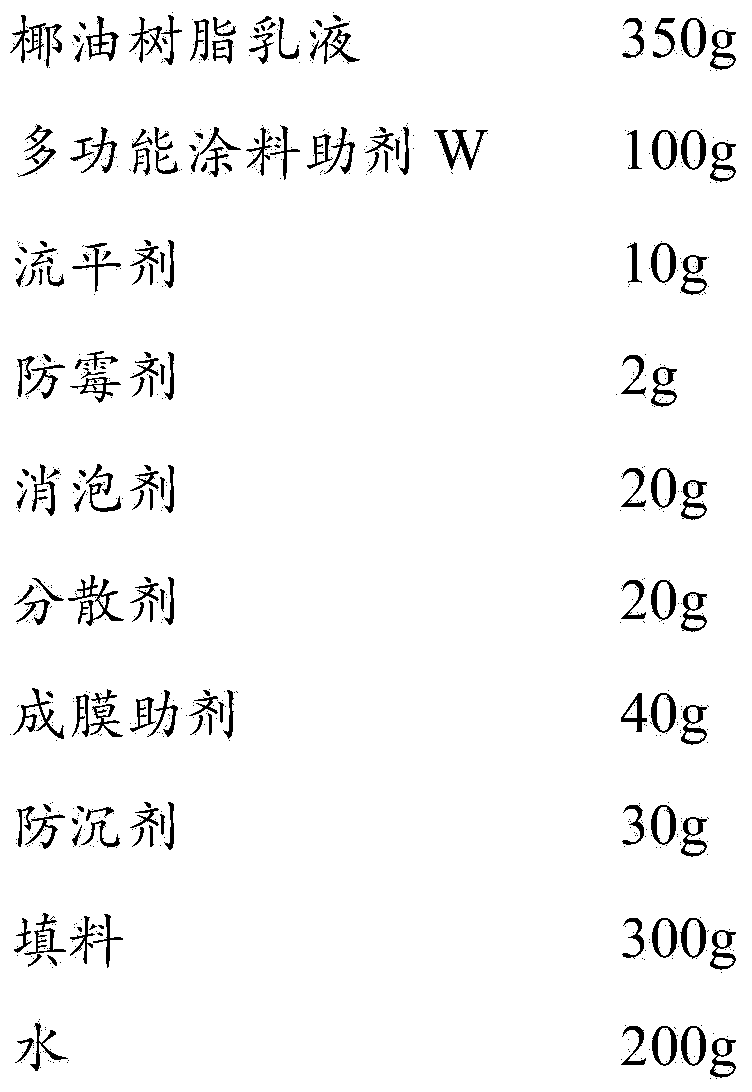

[0046] Embodiment 3 prepares multifunctional water-phase paint X

[0047] The components and their weights contained in Multifunctional Water Phase Coating X are:

[0048]

[0049] Among them, the coconut oil resin emulsion is A432-70, the leveling agent is BYK-333, the antifungal agent is PreventolCMK, the dispersant is EFKA-4010, the defoamer is EFKA-2020, and the anti-settling agent is BYK-410. The additive is butyl acetate. The filler is titanium dioxide and talcum powder, and the weight ratio of the two is 15:35.

[0050] Preparation:

[0051] 1) Accurately weigh each component;

[0052] 2) Add the coconut oil resin emulsion and water into the mixing tank;

[0053] 3) Start stirring, slowly add the leveling agent under the stirring condition of 400-500rpm, stir evenly, then add the dispersant, and stir for 5-10min;

[0054] 4) Add defoamer and filler in sequence, stir evenly, and disperse the mixture to a fineness below 30 microns;

[0055] 5) Increase the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com