Drying process for green bean seeds

A drying process and seed technology, applied in the field of crop seed drying process, to achieve the effect of easy implementation and low energy consumption

Active Publication Date: 2014-04-16

TIANJIN UNIV

View PDF8 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although there are many types of dryers available to dry green bean seeds, considering the high germination rate of green beans as seeds, the difficulty of process control in the drying process, and the energy consumption of drying, an appropriate dryer must be used. Drying technology for drying green bean seeds

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

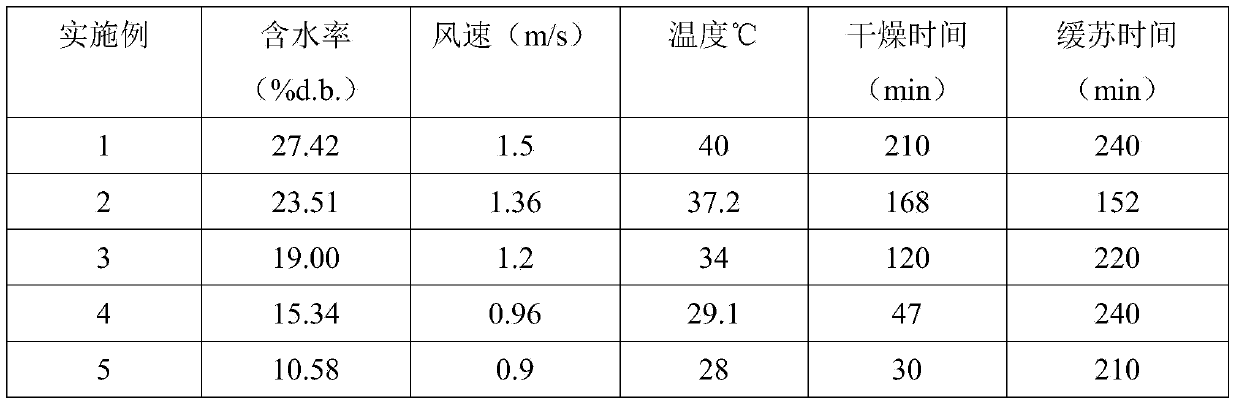

Embodiment 1

[0030] Embodiment 1, the actual slowing down time is 235min, and the slowing down ratio is: 1.1:1;

Embodiment 2

[0031] Embodiment 2, the actual slowing down time is 171min, and the slowing down ratio is: 1:1;

Embodiment 3

[0032] Embodiment 3, the actual slow recovery time is 225min, and the slow recovery ratio is 1.875:1;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

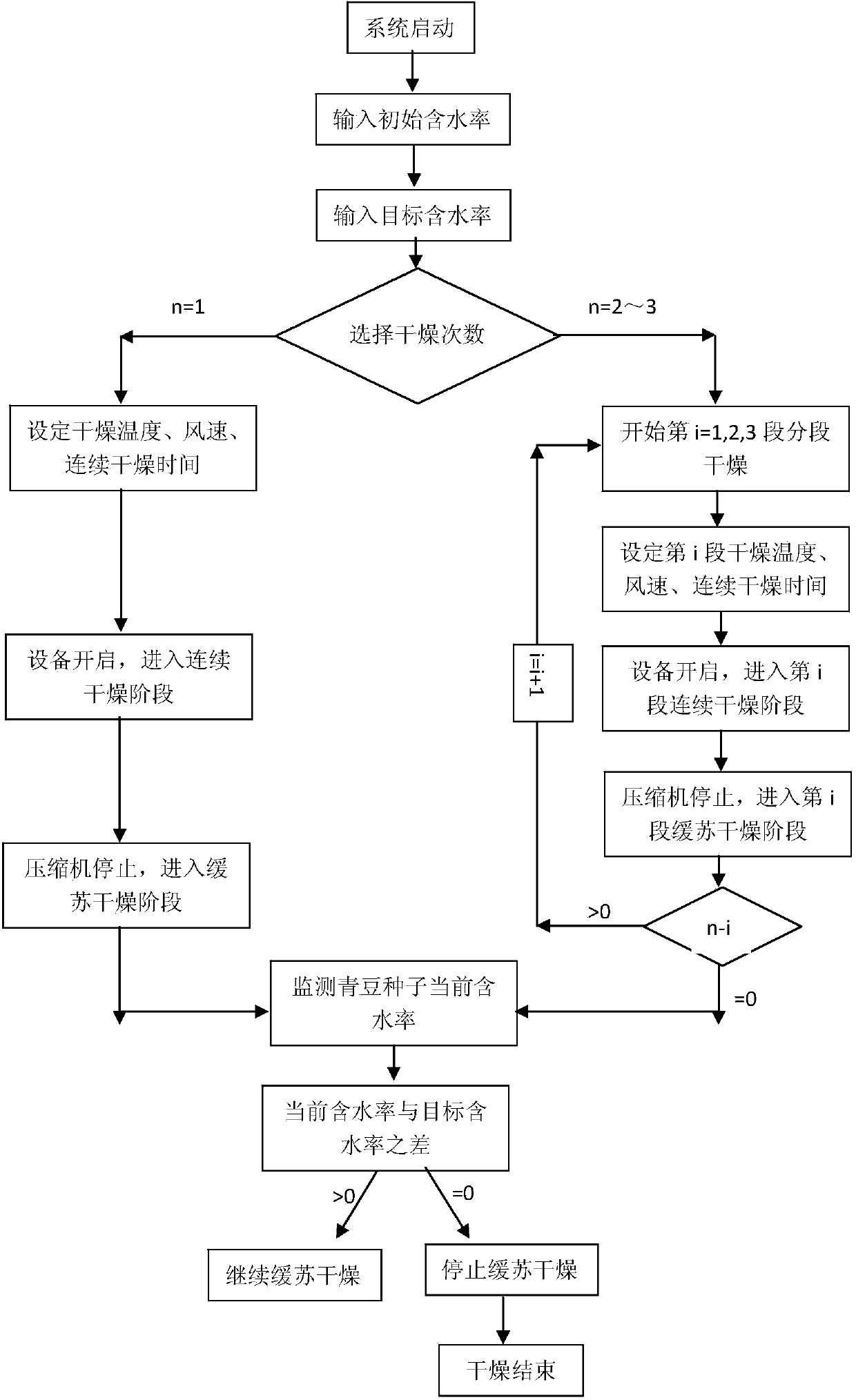

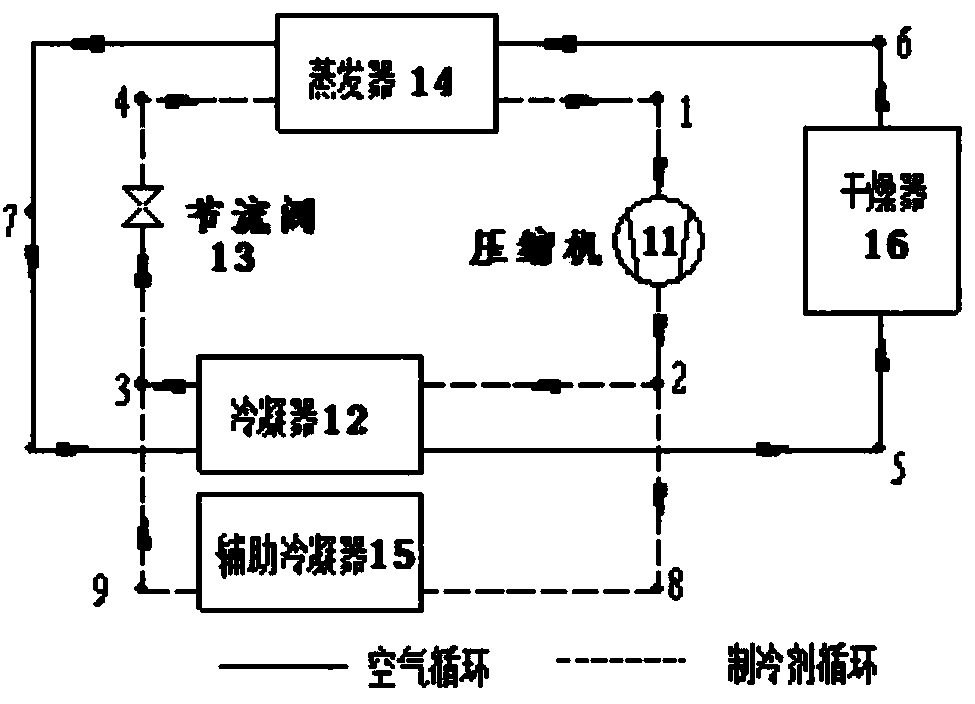

The invention discloses a drying process for green bean seeds which dries green bean seeds by applying an enclosed steam compression heat pump drying equipment with an auxiliary condenser. The drying process for green bean seeds includes the following steps of inputting an initial moisture content and a target moisture content of the green beans; determining cycling times for drying according to values of the initial moisture content, the target moisture content and the differential value between the initial moisture content and the target moisture content; setting process conditions, such as moisture content, drying temperature, wind speed performance, continuous drying time and tempering drying time and the like; shutting down the compressor and entering into the tempering drying stage after the continuous drying stage, monitoring the moisture content of the green beans in real time through a seed sample weighing system inside a drying oven, adjusting the tempering drying time according to the differential value between the current green bean seed moisture content and the target moisture content, and stopping the tempering drying and ending the drying process of green beans when the seed moisture content reaches the target value. The drying process for green bean seeds has the advantages of environmental protection, low consumption, high degree of automation, wide scope of application and good drying quality.

Description

technical field [0001] The invention relates to a drying process for crop seeds, in particular to a drying process for green bean seeds. Background technique [0002] Green beans are leguminous plants, which can be divided into green-skinned yellow-kernel soybeans and green-skinned green-kernel soybeans. Green beans were first produced in China, and the planting areas are mainly distributed in Northeast China, North China, Shaanxi, Sichuan and the lower reaches of the Yangtze River. Green beans are rich in protein, edible sugars, dietary fiber, isoflavones and anti-cancer health ingredients. Compared with soybeans, green beans have the characteristics of high sugar and low fat. In addition to being used as seeds for agricultural production, green bean seeds can also be used as auxiliary materials for vegetables or other foods or as raw materials to produce soybean milk powder, snack foods, etc. The moisture content of timely harvested green bean seeds is higher than the saf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F26B25/22A01F25/00

Inventor 杨昭朱恩龙朱宗升

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com