Measuring method for furfuraldehyde content of mixed solvent

A technology of mixed solvent and determination method, applied in the field of determination of furfural content in mixed solvent, can solve problems such as affecting the quality of mixed solvent, affecting use, etc., and achieves the effects of small error, reduced measurement error, and fast and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

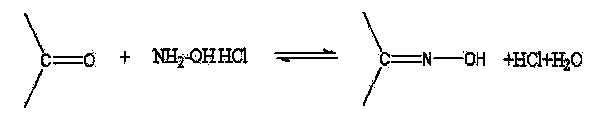

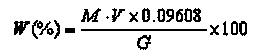

[0026] The technical scheme of the present invention is: a method for determining the content of furfural in a mixed solvent, using the hydrochloric acid hydroxylamine oximation method to react furfural with hydroxylamine hydrochloride ethanol solution, wherein bromophenol blue is used as an indicator, and under the best conditions , the solution after the reaction is dropped into the sodium hydroxide standard solution, and the color of the solution is compared with the standard color (the color of the original hydroxylamine hydrochloride ethanol solution). When the color of the two solutions is the same, it can be calculated by the volume of the sodium hydroxide standard solution The percentage by weight of furfural is suitable for mixed solvents in which other components except furfural do not react with hydroxylamine hydrochloride in the mixed solvent. The chemical reaction formula is:

[0027]

[0028] 1. instrument

[0029] General laboratory equipment and instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com