A kind of flexible thin-film solar cell module and its manufacturing method

A technology of solar cells and flexible films, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of poor reliability and safety, inconvenient production and manufacturing, complex production process, etc., achieve high safety and reliability, prevent radiation , the effect of increasing the light-receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

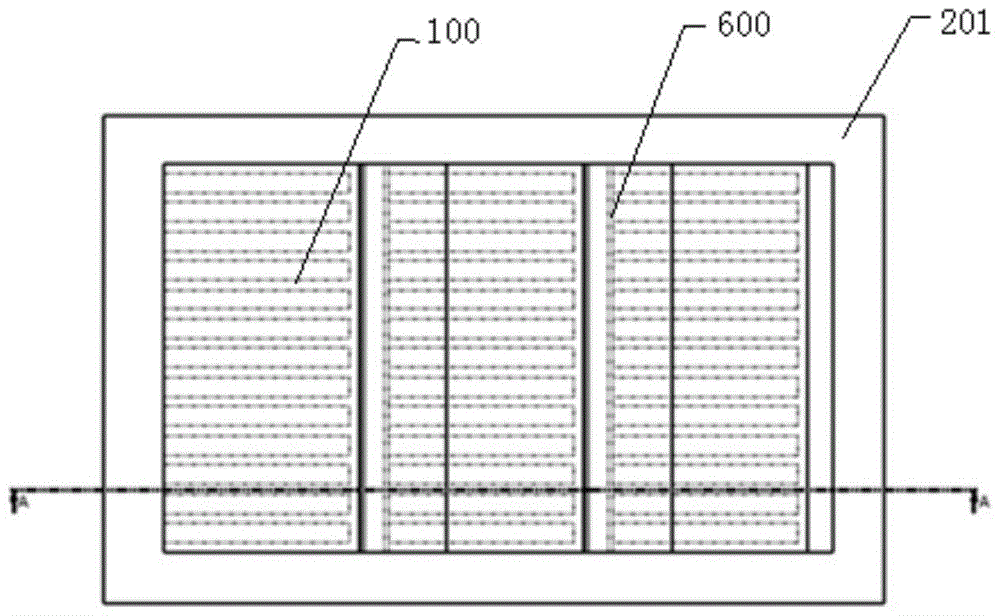

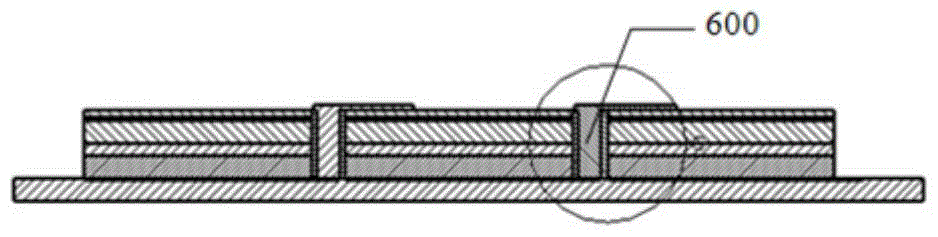

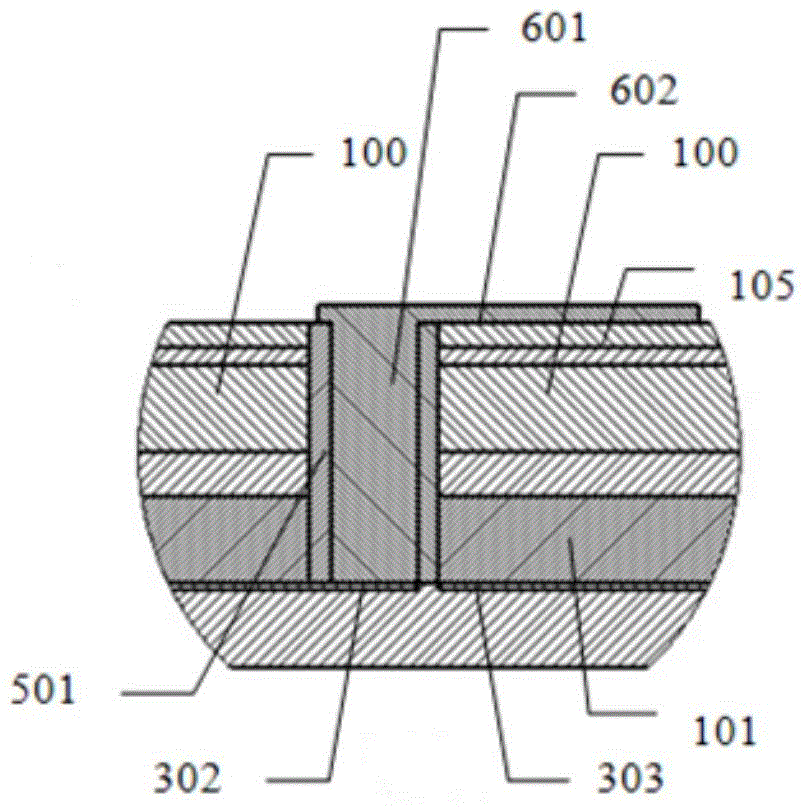

[0040] This embodiment provides a flexible thin-film solar cell module, its structure see Figure 1a to Figure 6c As shown, it includes a light-receiving surface blocking film 201 on which several first printed electrode layers 301 arranged at intervals are arranged, and each of the first printed electrode layers 301 is provided with a battery unit 100 . see Figure 2a-2c , the battery unit 100 is sequentially provided with a first electrode layer 101, a buffer layer 102, a light absorbing layer 103, a second electrode layer 104, and a flexible conductive base layer 105 on the first printed electrode layer 301, and each of the The two sides of the battery unit 100 are provided with an insulating layer 501, and there is a spacer area 502 between two adjacent battery units 100, and the first printed electrode layer 301 at the bottom of the previous battery unit 100 is removed from the battery unit 100. The bottom of the unit 100 extends to the separation area 502, and a bent se...

Embodiment 2

[0043] This embodiment provides a specific structure of a flexible thin film solar cell module, specifically as follows:

[0044] Such as Figure 3a-3b The light-receiving surface blocking film 201 shown includes an inner side 202 and an outer side 203, and the light-receiving surface blocking film outer side 203 of the light-receiving surface blocking film 201 is provided with an anti-ultraviolet coating, which effectively slows down the aging of the light-receiving surface blocking film, and also prevents The radiation of ultraviolet rays to the battery slows down the aging speed of the battery. The inner side 202 of the light-receiving surface blocking film 201 is provided with a hot-melt adhesive material, which facilitates the press-fit assembly of the battery unit and the light-receiving surface blocking film.

[0045] Such as Figures 4a-4c As shown, a number of first printed electrode layers 301 arranged at intervals are arranged on the light-receiving surface blocki...

Embodiment 3

[0048] This embodiment provides a method for manufacturing a flexible thin-film solar cell module, comprising the following steps:

[0049] First prepare the battery cell 100, such as Figure 2a-2c As shown, the process of preparing the battery unit 100 includes: preparing the second electrode layer 104 on the flexible conductive substrate 105 by molecular beam epitaxy, and then sequentially preparing the optical electrode layer 104 by sputtering. The absorption layer 103 , the buffer layer 102 and the first electrode layer 101 . The molecular beam epitaxy method can separately heat and control the source and the substrate; the shutter can be used to precisely control the doping, combination and thickness, which is an atomic-level growth technology, which is conducive to the growth of multi-layer heterostructures; It is not carried out under thermal equilibrium conditions, but is a kinetic process, so crystals that are difficult to obtain in general thermal equilibrium growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com