Method for preparing non-aqueous electrolyte suitable for high-energy density lithium ion batteries

A lithium ion battery, non-aqueous electrolyte technology, applied in the field of electrochemistry, can solve the problems of difficult control of the uniformity of the coating layer on the surface of the positive electrode material, the decrease of the specific capacity of the battery, the increase of the production cost, etc., so as to improve the high-voltage cycle performance, The effect of inhibiting oxidative decomposition and reducing flatulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 (comparative example):

[0020] In the glove box In the glove box (H 2 O 2 2 >99.99%) to prepare lithium-ion electrolyte: EC:EMC=1:2(wt%), lithium salt concentration is 1M lithium hexafluorophosphate (LiPF 6 ), a total of 200g was packed in a fluorinated bottle, and the electrolyte was used as the electrolyte of the lithium-ion battery, marked as A, and assembled into a battery.

Embodiment 2

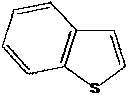

[0022] A lithium ion battery electrolyte additive, structural formula is as follows:

[0023] (1)

[0024] Use the preparation method of the electrolyte of above-mentioned additive: in glove box (H 2 O 2 2 >99.99%) to prepare lithium-ion electrolyte: EC:EMC=1:2 (wt%), the concentration of lithium salt is 1M lithium hexafluorophosphate (LiPF6), a total of 200g. After adding 0.5wt% of the additive shown in the structural formula (1), it was packed in a fluorinated bottle, and the electrolyte was used as the electrolyte of the lithium-ion battery, marked as B, and the battery was assembled.

Embodiment 3

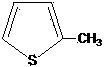

[0025] Embodiment 3: a kind of lithium ion battery electrolyte additive, structural formula is as follows:

[0026] (2)

[0027] Use the preparation method of the electrolyte of above-mentioned additive: in glove box (H 2 O 2 2>99.99%) to prepare lithium-ion electrolyte: EC:EMC=1:2 (wt%), the concentration of lithium salt is 1M lithium hexafluorophosphate (LiPF6), a total of 200g. After adding 0.5wt% of the additive shown in the structural formula (2), it was packed in a fluorinated bottle, and the electrolyte was used as the electrolyte of the lithium-ion battery, marked as C, and the battery was assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com