A method for preparing controllable network three-dimensional graphene through chemical bond connection

A graphene and chemical bond technology, applied in the field of nanomaterials, can solve the problems of inconspicuous spatial network structure, insufficient connection force between sheets, limiting three-dimensional graphene, etc., and achieves the effect of wide application prospect and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

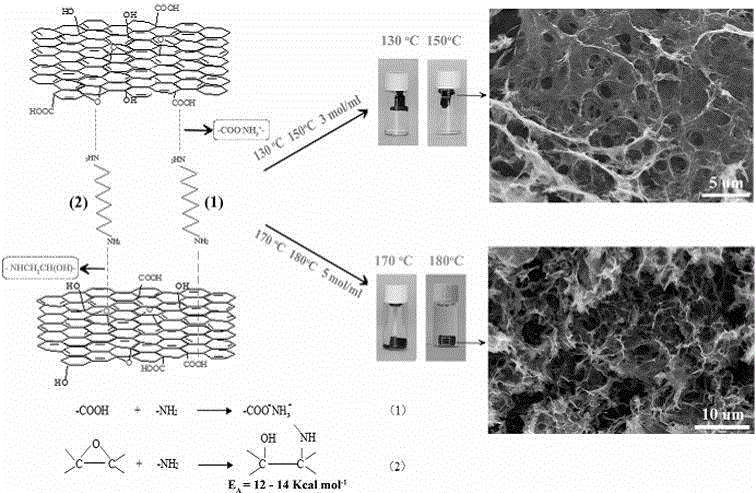

Method used

Image

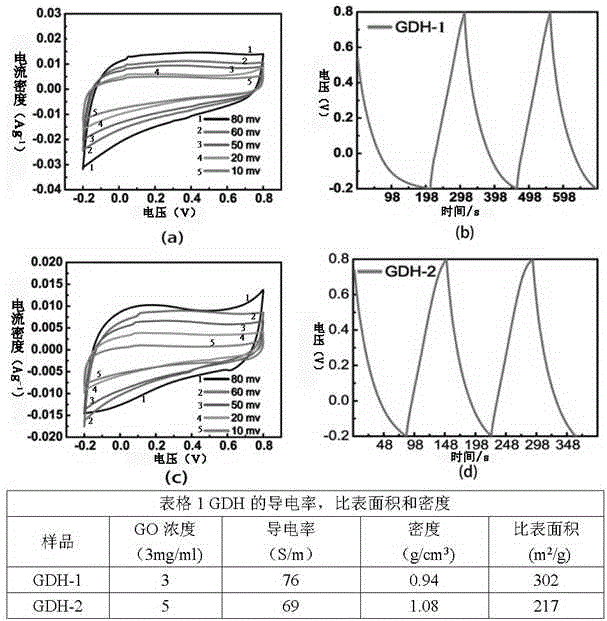

Examples

Embodiment 1

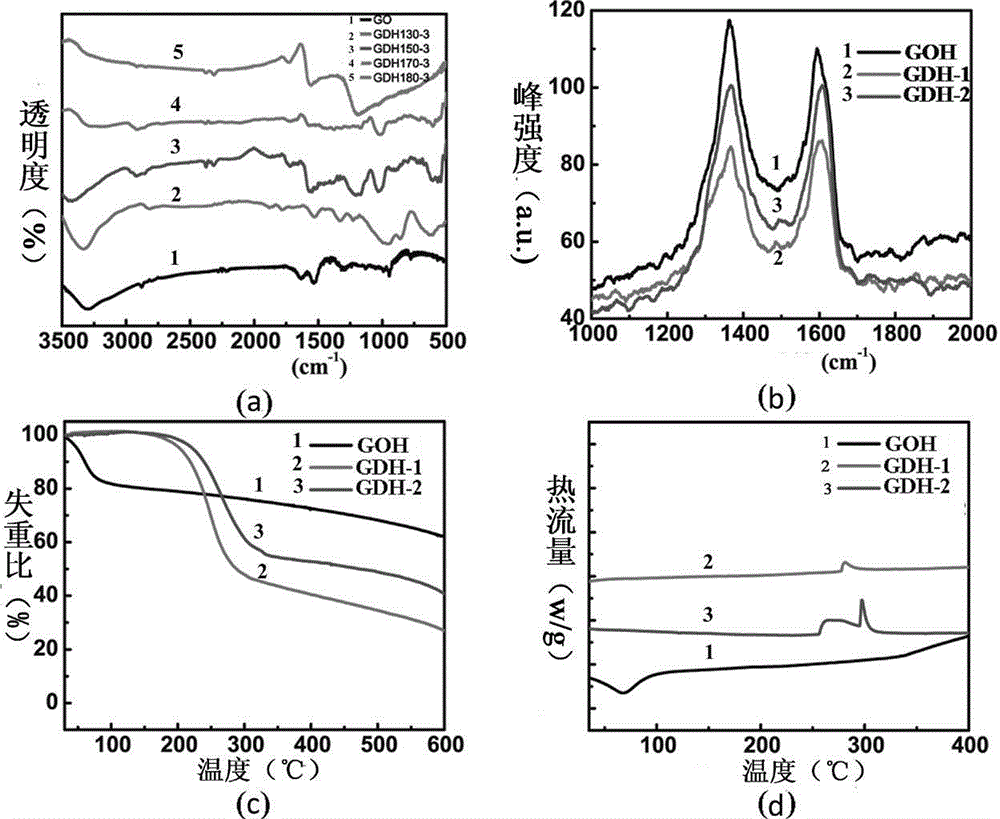

[0027] 1. Preparation of Graphite Oxide

[0028] Add 4 g of graphite to 90 ml of concentrated H 2 SO 4 (98%) solution, stirred in ice bath for 30min, then slowly added 11.8g of KMnO 4 , stirred for 30min; then reacted the solution in an oil bath at 30°C for 2h, then slowly added 120ml of deionized water (drip speed 4~6s / drop) to the solution to dilute the solution; then heated the solution to 90°C for 30min, added Dilute the solution with 210ml of deionized water; then cool the solution to 60°C, add 10ml of H 2 o 2 (30%) to obtain an orange-yellow solution; then add 500ml of 5% HCl solution, let stand for 3h and pour out the supernatant to remove metal ions; then use deionized water for centrifugal washing to remove excess acid until the solution is neutral properties; and then freeze-dry the obtained solution in a lyophilizer with a temperature of -48°C and a pressure lower than 18Pa to obtain low-density graphene oxide (GO).

[0029] 2. Grafting 1,8-octanediamine on gra...

Embodiment 2

[0034] According to the method of Example 1, 4-4-methine-bis(2-chloroaniline) (BisAmineA / S) was used instead of 1,8-octanediamine as a link between GO sheets, according to the mass ratio GO:GOD=1:1 ratio to configure GO and GOD mixture, add solvent, configure a mixed solution with a concentration of 5mg / ml, put it into a polytetrafluoroethylene reactor, and prepare three-dimensional network graphene at a temperature of 180°C .

Embodiment 3

[0036] According to the method of Example 1, 4,4-bis(4-aminophenoxy)biphenyl (BAPB) was used instead of 1,8-octanediamine as a link between GO sheets, according to the mass ratio of GO: The ratio of GOD=1:6 is used to configure the mixture of GO and GOD, add a solvent to prepare a mixed solution with a concentration of 8 mg / ml, put it into a polytetrafluoroethylene reactor, and prepare three-dimensional network graphene at a temperature of 150 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com