A microwave rapid treatment method for dye wastewater

A technology of dye wastewater and treatment method, which is applied in the field of dye wastewater treatment, can solve the problems of long treatment cycle and low treatment efficiency, and achieve the effects of improved degradation efficiency, high degradation efficiency, and improved efficiency and rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the treatment of wastewater containing solvent blue 36 dyes

[0026] Adjust the pH of the solvent blue 36 dye wastewater to 5.0, add nano-zero-valent iron, and pass the solid-liquid mixed solution of the dye wastewater and nano-zero-valent iron through the microwave field under aerobic or anaerobic conditions; Under aerobic or anaerobic conditions, the solid-liquid mixed solution of dye wastewater and nano-zero-valent iron stays for a period of time and then is filtered through a microporous membrane to obtain a decolorized aqueous solution.

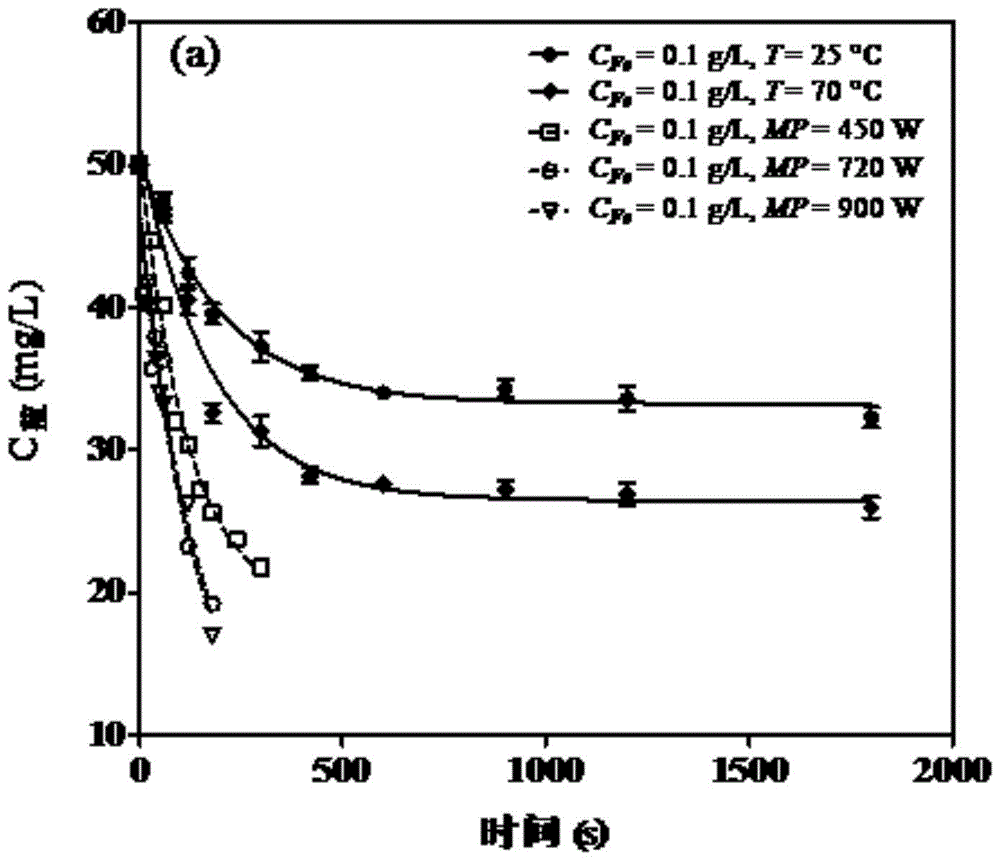

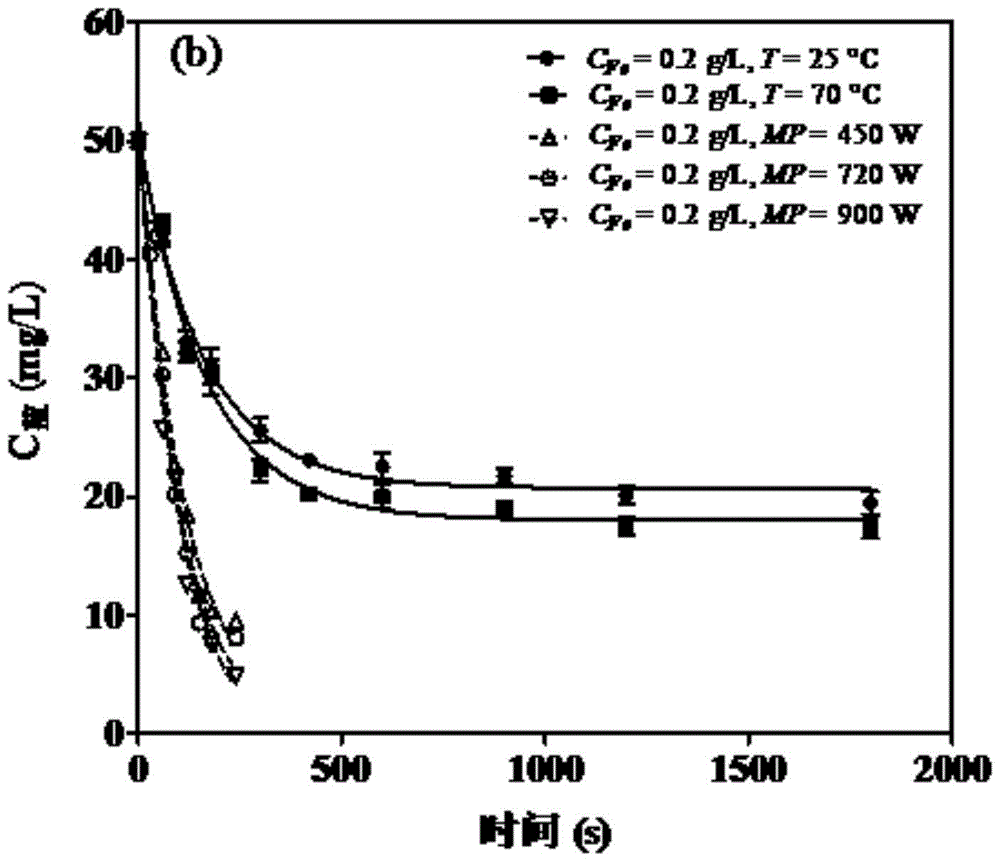

[0027] (1) Influence of microwave field power

[0028] Microwaves with different powers (MP=0W, 450W, 720W, 900W) and different concentrations of nano-zero-valent iron (concentration of nano-zero-valent iron in the dye solution) (C Fe =0.1g / L, 0.2g / L) at the same time, the degradation curve of 50mg / L solvent blue solution with time is shown in Figure 1.

[0029] It can be seen from Figure 1 that after the microwave...

Embodiment 2

[0035] Embodiment 2, the treatment method of the dye wastewater containing reactive yellow K-RN

[0036] Adjust the pH of reactive yellow K-RN dye wastewater to 5.0, add nanometer zero-valent iron, and pass the solid-liquid mixed solution of dye wastewater and nanometer zerovalent iron through the microwave field under aerobic or anaerobic conditions; in the microwave field , under aerobic or anaerobic conditions, the solid-liquid mixed solution of dye wastewater and nano-zero-valent iron stays for a period of time and then is filtered through a microporous membrane to obtain a decolorized aqueous solution.

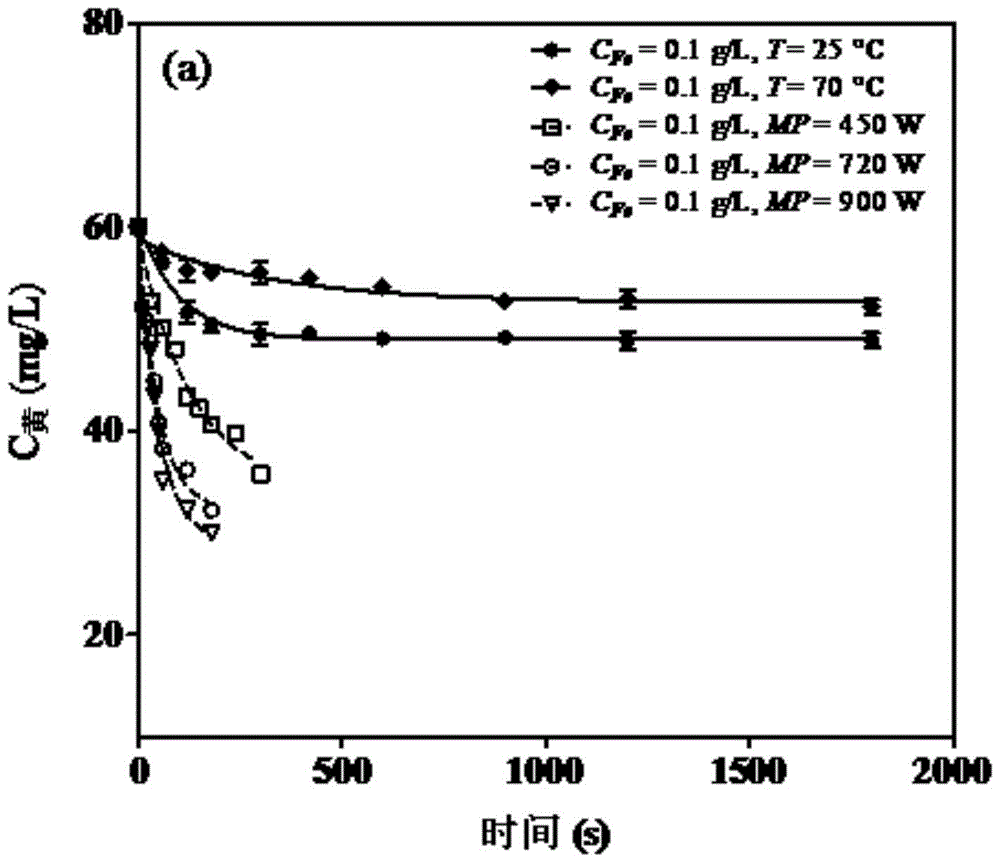

[0037] (1) Influence of microwave field power

[0038] Microwaves with different powers (WW=0W, 450W, 720W, 900W) and different concentrations of nano-zero-valent iron (C Fe =0.1g / L, 0.3g / L) at the same time, the degradation curve of 60mg / L solvent blue solution with time is shown in Figure 2.

[0039] It can be seen from Figure 2 that after the microwave field is added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com