Fluorescence coating

A fluorescent coating and fluorescent powder technology, applied in the field of fluorescent coatings, can solve the problems of affecting escape, the trapped persons cannot identify the evacuation position and direction in time, and lose their function, and achieves simple manufacturing process, stable color and good anti-oxidation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

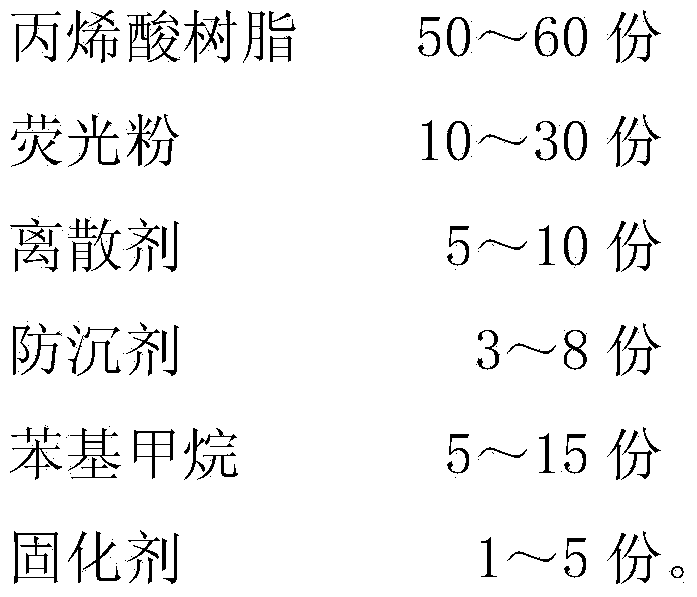

[0020] A fluorescent paint, the parts by weight of each component in the fluorescent paint are as follows:

[0021]

[0022] The above-mentioned curing agent is a silicon epoxy curing agent.

Embodiment 2

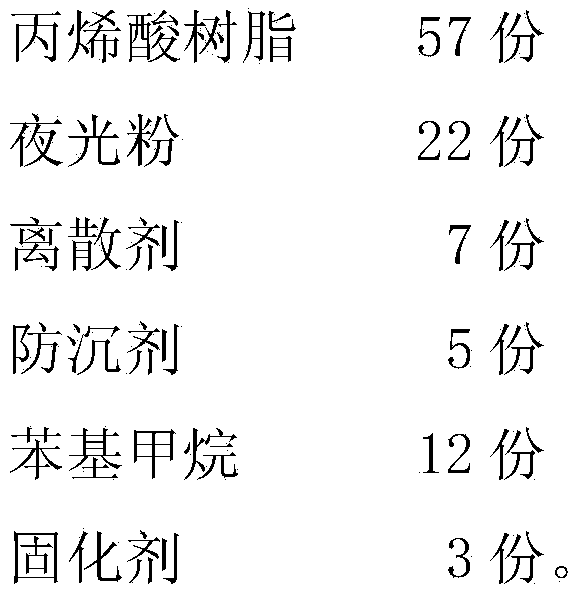

[0024] A fluorescent paint, the parts by weight of each component in the fluorescent paint are as follows:

[0025]

[0026] The above-mentioned curing agent is a silicon epoxy curing agent.

Embodiment 3

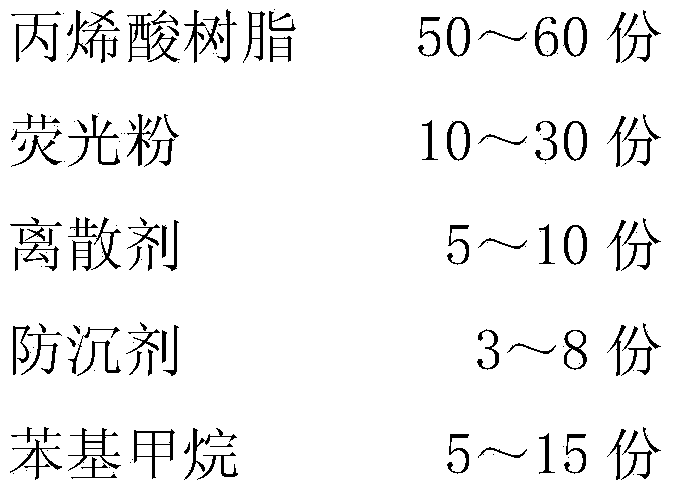

[0028] A fluorescent paint, the parts by weight of each component in the fluorescent paint are as follows:

[0029]

[0030] The above-mentioned curing agent is a silicon epoxy curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com