Intelligent temperature regulating type heat reflection heat insulation coating and preparation method thereof

A technology of thermal insulation coating and heat reflection, applied in the direction of reflection/signal coating, coating, etc., can solve the problems of declared safety impact, construction personnel and surrounding environment impact, low weather resistance, etc., to overcome the impact on the environment, reduce Heat island effect, the effect of avoiding drastic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

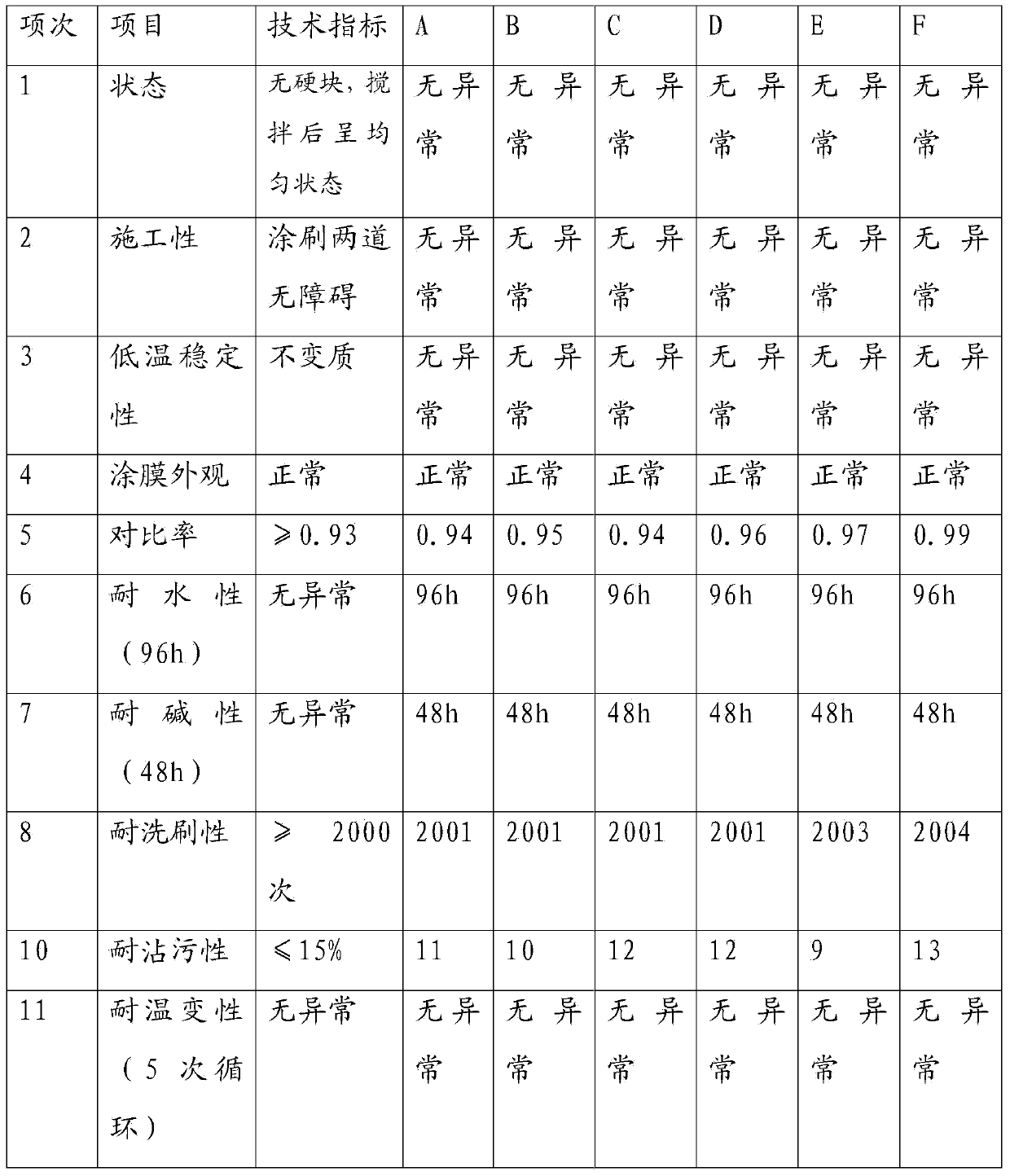

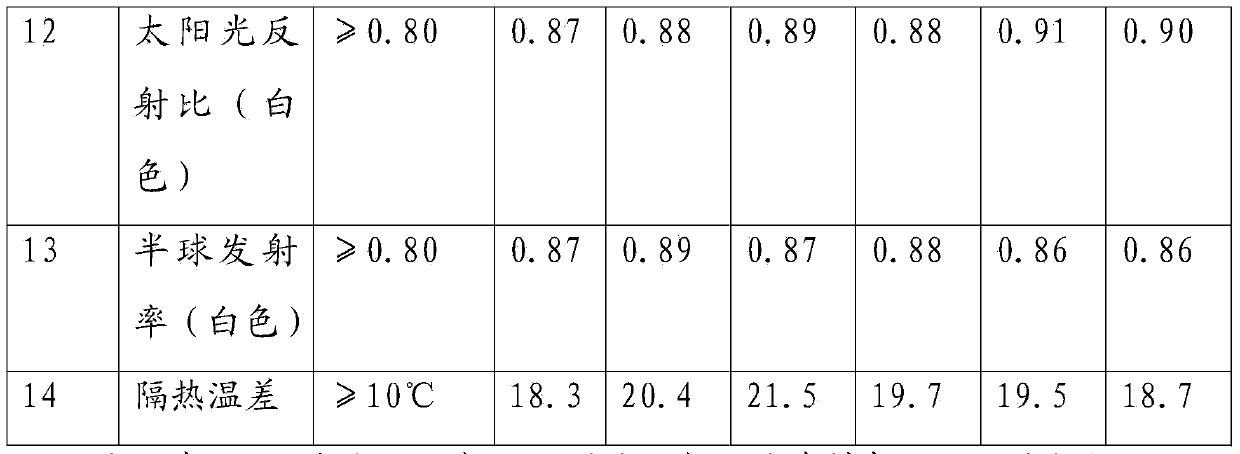

Examples

Embodiment 1

[0028] Take 100g of rutile titanium dioxide (using R-996) and put it into a beaker, add 500ml of ethanol, stir for 5-10 minutes to dissolve the rutile titanium dioxide in ethanol, then add 3-aminopropyltriethoxysilane into the beaker (Using KH550) 8.5g, stirred evenly, placed in a condensing reflux device, and condensed and refluxed at 60°C for 3 hours to obtain a mixture, which was filtered, washed, and dried under normal conditions to obtain 3-aminopropyl tris Ethoxysilane modified rutile titanium dioxide.

[0029] Weigh 200g of paraffin-type phase-change microcapsules (model RUBITHERM RT27) into a beaker, add 800ml of ethanol, mix well, add 80g of 3-aminopropyltriethoxysilane modified rutile-type titanium dioxide into the beaker, and Place in a condensing reflux device, adjust the temperature of the water bath to 80°C, and carry out condensing and reflux operation for 4 hours. After reflux, filter and wash to obtain high-reflective phase-change microcapsules.

[0030] Add ...

Embodiment 2

[0033] Take 120g of rutile titanium dioxide (using NTR-606) and put it into a beaker, add 500ml of ethanol, stir for 5-10 minutes to dissolve the rutile titanium dioxide in ethanol, then add tridecafluorooctyltriethoxysilane into the beaker (Using the modifier of ACTYGLON-G617 model) 11g, after stirring evenly, place it in the condensing reflux device, carry out the condensing reflux operation at 70°C for 4 hours to obtain a mixture, which is filtered, washed and dried under normal conditions Tridecafluorooctyltriethoxysilane modified rutile titanium dioxide was obtained.

[0034] Weigh 180g of acrylic wall-type phase-change microcapsules (model ESM-44) into a beaker, add 800ml of ethanol, mix well, and add 110g of tridecafluorooctyltriethoxysilane modified rutile titanium dioxide into the beaker , adjusting the temperature of the water bath to 70° C., performing condensation and reflux operation for 5 hours, and obtaining high-reflective phase-change microcapsules by filterin...

Embodiment 3

[0038] Take 100g of rutile titanium dioxide (using R-258) and put it into a beaker, add 500ml of ethanol, stir for 5-10 minutes, dissolve the rutile titanium dioxide in ethanol, and then add γ-(methacryloyloxy) propane to the beaker 7.5g of trimethoxysilane (using KH570), stirred evenly, and condensed and refluxed at 70°C for 6 hours to obtain a mixture. The mixture was filtered, washed and dried under normal conditions to obtain γ-(methacryloyloxy ) Propyltrimethoxysilane modified rutile titanium dioxide.

[0039] Weigh 160g of acrylic wall-type phase-change microcapsules (model ESM-44) into a beaker, add 800ml of ethanol, mix well, add γ-(methacryloyloxy)propyltrimethoxysilane to the beaker to modify 85g of non-volatile rutile titanium dioxide, adjust the temperature of the water bath to 75°C, carry out the condensation and reflux operation for 6 hours, after reflux, filter and wash to obtain high-reflective phase-change microcapsules.

[0040] Add 120g of water, 2.5g of am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com