Protein-based wood adhesive and preparation method thereof

A wood adhesive and protein-based technology, which is applied in the field of protein-based wood adhesive and its preparation, can solve the problems of limited price application range, low market acceptance, and high dark brown color, and achieve lower temperature, low price, and simple synthesis method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

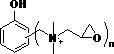

[0053] Synthesis of Quaternary Ammonium Epoxy Resin (Compound IA)

[0054] (IA)

[0055] Add 1404.4 g of water into a 2000 mL three-necked flask, and then slowly add 2,4,6-tris-(dimethylaminomethyl)phenol (DMP30, 167.5 g, 661 mmol, 95%). After the addition, the solution was cooled to 0°C, and epichlorohydrin (174.8 g, 1.89 mol) was slowly added dropwise, and the temperature was controlled below 25°C during the dropwise addition. After dropping, stir at this temperature for 2 h, then increase the temperature to 30°C and stir for 1 h to obtain the aromatic curing agent DMP30-epichlorohydrin IA.

Embodiment 2

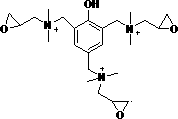

[0057] Synthesis of Quaternary Ammonium Epoxy Resin (Compound IB)

[0058] (IB)

[0059] Add 1048.8 g of water into a 2000 mL three-necked flask, and then slowly add 3,5-bis-(dimethylaminomethyl)phenol (137.5 g, 661 mmol). After the addition, the solution was cooled to 0°C, and epichlorohydrin (124.7 g, 1.22 mol) was slowly added dropwise, and the temperature was controlled to be less than 25°C during the dropwise addition. After dropping, stir at this temperature for 2 h, then raise the temperature to 30°C and stir for 1 h to obtain the aromatic curing agent 3,5-bis-(dimethylaminomethyl)phenol-epichlorohydrin IB.

Embodiment 3

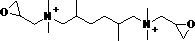

[0061] Synthesis of Quaternary Ammonium Epoxy Resin (Compound IC)

[0062] (IC)

[0063] Add 1048.8 g of water into a 2000 mL three-necked flask, and then slowly add 2,4-bis-(dimethylaminomethyl)phenol (137.5 g, 661 mmol). After the addition, the solution was cooled to 0°C, and epichlorohydrin (124.7 g, 1.22 mol) was slowly added dropwise, and the temperature was controlled to be less than 25°C during the dropwise addition. After dropping, stir at this temperature for 2 h, then raise the temperature to 30°C and stir for 1 h to obtain the aromatic curing agent 2,4-bis-(dimethylaminomethyl)phenol-epichlorohydrin IC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com