Single-matrix white fluorescent powder for warm white LED (Light Emitting Diode) and preparation method thereof

A fluorescent powder and warm white light technology, applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of low luminous efficiency and achieve the effect of simple operation, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for warm white fluorescent powder for LED, comprising the following steps:

[0030] 1) According to the molar ratio of 0.5:0.5:1:1:x / 2:y / 4:z / 2 (x=0.15, y=0.05, z=0.0025), respectively weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O. WO 3 、Tm 2 o 3 , Tb 4 o 7 and Sm 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0031] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to heat up to 200°C at a rate of 1°C / min, then to 500°C at a rate of 3°C / min, then to 1100°C at a rate of 5°C / min, hold for 3 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ , yTb 3+ , zSm 3+ White light phosphor, where x=0.15, y=0.05, z=0.0025.

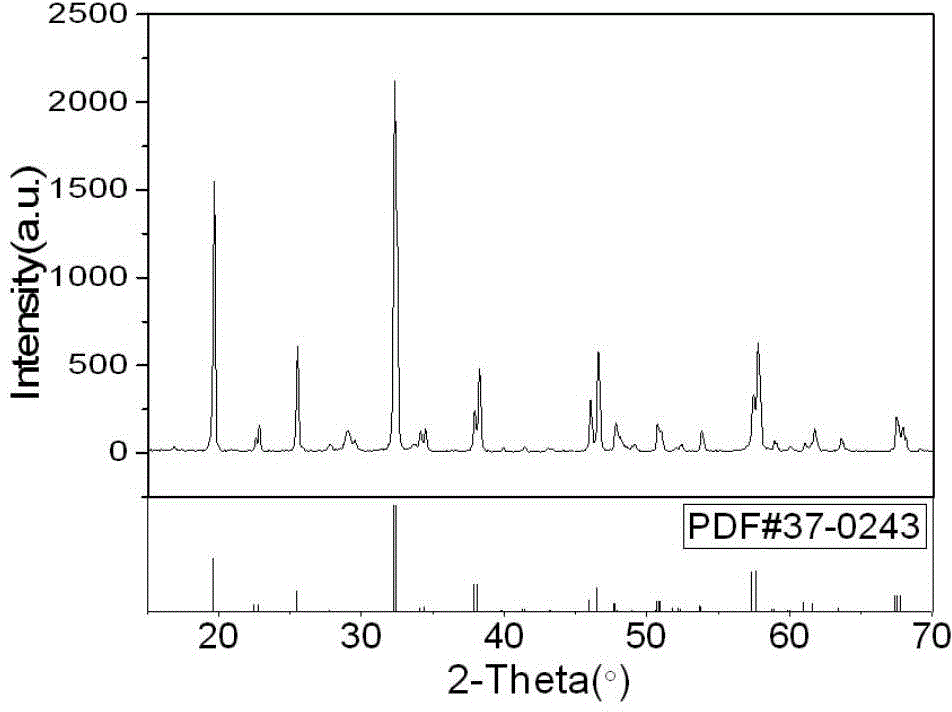

[0032] see figure 1 ,From figure 1 It can be seen that NaLaMgWO 6 :xTm 3+ , yTb 3+ , zSm 3+ Powder and NaLaMgWO 6 The standard card JCPDS#37-0243 is completely consistent, and th...

Embodiment 2

[0034] A preparation method of white phosphor powder for LED, comprising the following steps:

[0035] 1) Weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O. WO 3 、Tm 2 o 3 , Tb 4 o 7 and Sm 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0036] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to heat up to 100°C at a rate of 1°C / min, then to 300°C at a rate of 2°C / min, and then to 1000°C at a rate of 7°C / min, hold for 5 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ , yTb 3+ , zSm 3+ White light phosphor, where x=0.25, y=0.01, z=0.01.

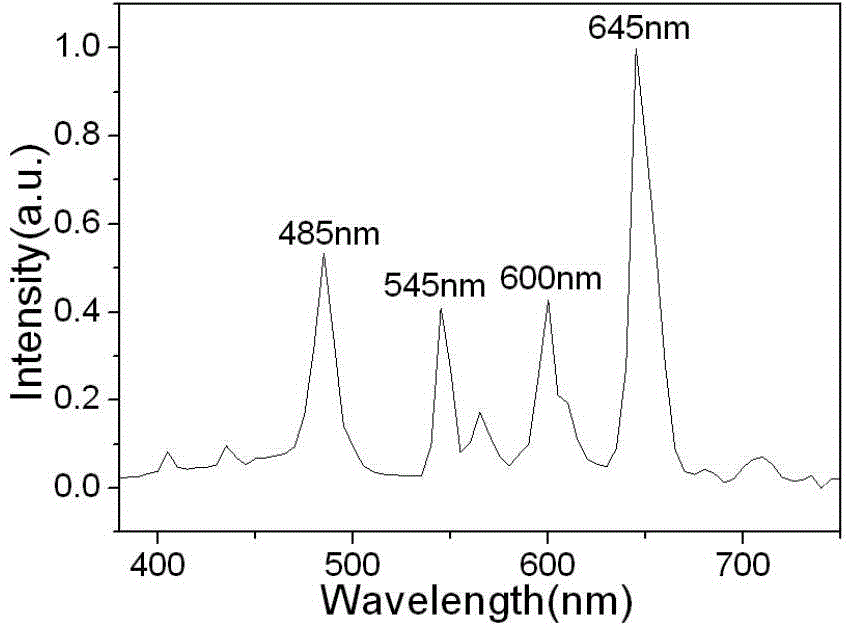

[0037] see figure 2 ,From figure 2 It can be seen that the emission band of the phosphor is distributed in the range of 450nm to 670nm, and the emission spectrum is mainly composed of four strong emission peaks, which are at 480nm, 545nm, 600nm, and 645nm respectively. Among them, 4...

Embodiment 3

[0039] A preparation method of white phosphor powder for LED, comprising the following steps:

[0040] 1) Weigh Na 2 CO 3 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O. WO 3 、Tm 2 o 3 , Tb 4 o 7 and Sm 2 o 3 , and the above raw materials are mixed and ground to obtain a mixed powder;

[0041] 2) Put the mixed powder in an alumina crucible and sinter in a resistance furnace. The sintering system in the resistance furnace is to heat up to 300°C at a rate of 3°C / min, then to 600°C at a rate of 4°C / min, then to 1200°C at a rate of 5°C / min, hold for 3 hours, and finally cool with the furnace , to get NaLaMgWO 6 :xTm 3+ , yTb 3+ , zSm 3+ White light phosphor, where x=0.05, y=0.01, z=0.0025.

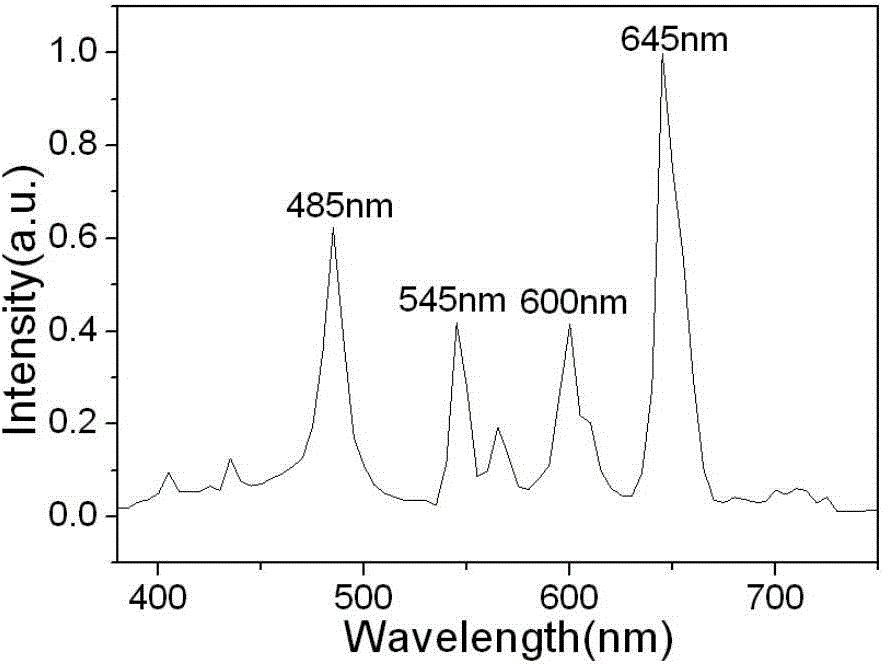

[0042] see image 3 ,From image 3 It can be seen that the emission band of the phosphor is distributed in the range of 450nm to 670nm, and the emission spectrum is mainly composed of four strong emission peaks, which are at 480nm, 545nm, 600nm, and 645nm respectively. Among them, 480nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com