Cos2 catalyzed high-capacity hydrogen storage alloy and preparation method thereof

A hydrogen storage alloy and high-capacity technology, which is applied in the field of hydrogen storage alloy materials, can solve the problems of poor hydrogen absorption and desorption cycle stability of ball-milled magnesium-based alloys, and achieve excellent hydrogen absorption and desorption kinetics, high hydrogen absorption and desorption capacity, and high The effect of hydrogen absorption and desorption capacity

Inactive Publication Date: 2015-09-16

INNER MONGOLIA UNIV OF SCI & TECH

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the metastable structure formed by ball milling will gradually disappear in the process of multiple hydrogen absorption and desorption cycles, so that the hydrogen absorption and desorption cycle stability of ball milled magnesium-based alloys is very poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Example 1: Mg 20 Y 3 Zr 1 Ni 9.5 co 2 Fe 0.5 +6 wt.%CoS 2 .

Embodiment 2

[0031] Example 2: Mg 22 Y 1 Zr 1 Ni 9.5 co 2 Fe 0.5 +6 wt.%CoS 2 .

Embodiment 3

[0032] Example 3: Mg 19 Y 4 Zr 1 Ni 9.5 co 2 Fe 0.5 +6 wt.%CoS 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

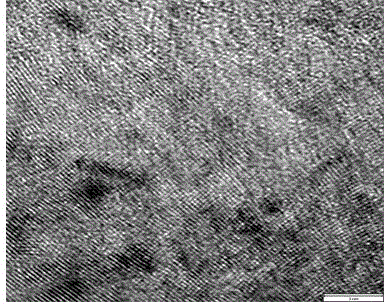

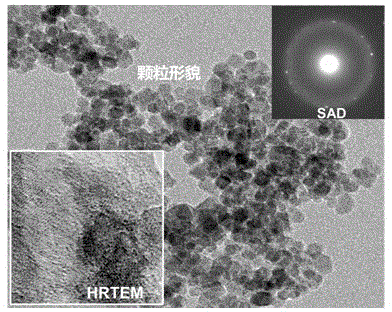

The invention discloses CoS2-catalyzed high-capacity hydrogen storage alloy and a preparation method thereof. The hydrogen storage alloy comprises the following component: Mg[24-x-y]Y[x]Zr[y]Ni[12-z-m]Co[z]Fe[m] and n wt.% of CoS2, wherein x is more than 1 and less than 4, y is more than 0.5 and less than 2, z is more than 1 and less than 3, m is more than 0.2 and less than 1, and n is more than 2 and less than 10. The preparation method comprises the following steps: heating and smelting under the protection of inert gas, filling a copper casting mould with molten alloy, putting into a quartz tube, and after heating and melting, continuously spraying down to the surface of a rotary water-cooling copper roller through the bottom of the quartz tube under the pressure of the inert gas to obtain quickly quenched alloy; putting ground alloy powder into a ball mill tank for pre-ball-milling; after pre-ball-milling, adding a catalyst CoS2 and continuing to perform ball-milling under the same process to obtain alloy powder with nanocrystalline-noncrystalline structure. According to the preparation method, the thermal stability of alloy hydride is reduced, the gaseous hydrogen absorption and desorption capacity of the alloy is increased, and the dynamics performance of the alloy is improved.

Description

technical field [0001] The present invention relates to a CoS 2 Catalyzed high-capacity hydrogen storage alloys and methods for their preparation, particularly involving a CoS 2 Catalytic high capacity Mg-Y-Zr-Ni-Co-Fe based Mg 2 The invention relates to Ni-type hydrogen storage alloy powder and a preparation method thereof, belonging to the technical field of hydrogen storage alloy materials. Background technique [0002] Mg 2 Ni-type alloys are considered as the most promising hydrogen storage materials and anode materials for Ni-MH batteries due to their high hydrogen storage capacity, such as Mg 2 NeH 4 3.6 wt.%, Mg 2 CoH 5 4.5 wt.%, Mg 2 FeH 6 It is 5.4 wt.%. [0003] However, the extremely high thermal stability of the above-mentioned hydrides leads to extremely poor hydrogen absorption and desorption kinetics. In order to overcome the above shortcomings, various methods, including mechanical alloying, rapid quenching of melts, adding catalysts, etc., have b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C30/00C22C1/02B22F1/00

Inventor 张羊换胡锋冯佃臣

Owner INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com