Three-core yarn spinning device and process

A technology of core yarn and process, which is applied in the direction of continuous winding spinning machine, spinning machine, yarn, etc., and can solve the problems of easy deformation of clothes and insufficient resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

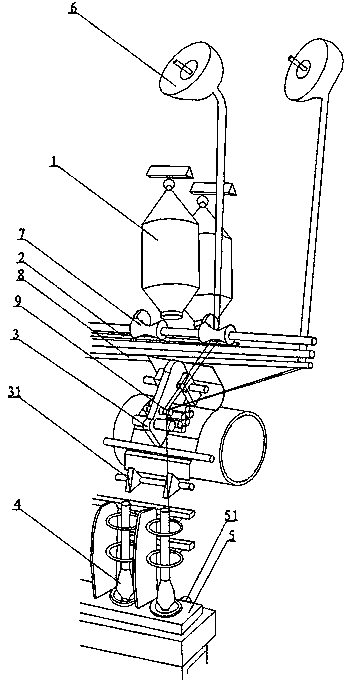

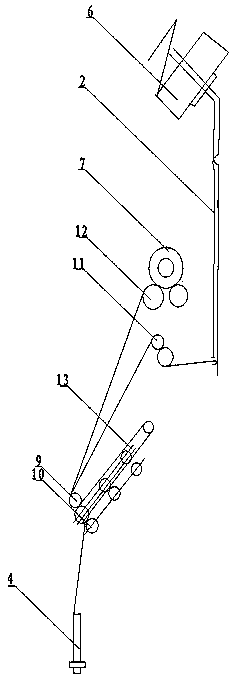

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: 16sCD (40D nylon / 34F+40D)+70D yarn

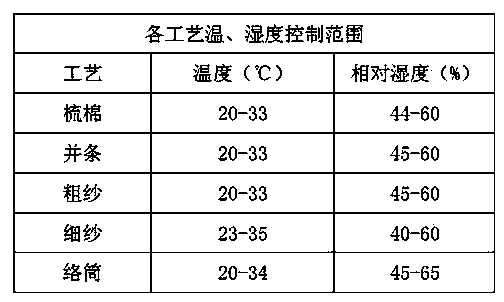

[0029] In the spinning process of the three-core yarn in this example, the raw materials are elastic yarn (filament), non-elastic yarn (filament) and staple fiber, elastic yarn: non-elastic yarn: staple fiber (addition amount) = 2:1: 7. The elastic yarn is made of spandex, of which spandex consists of two parts, half of which is 40D, and the other half is 70D; the non-elastic yarn is nylon filament, which is 40D; the staple fiber is cotton fiber, which is 1.6D. The specific process is as follows:

[0030] (1) Opening and cleaning process:

[0031] The cotton opening and cleaning process is sequentially as follows: cotton grabbing machine → pre-cleaning machine → multi-bin cotton mixing machine → fine cleaning machine → cotton condenser, the raw materials are gently opened with dust sticks to remove foreign particles, broken fibers and dust, and use multiple The silo makes the raw materials fed at the same time output ...

Embodiment 2

[0051] Embodiment 2: 16S polyester (50D polyester+40D)+70D yarn

[0052] In this embodiment, the raw materials are elastic filaments (long filaments), non-elastic filaments (long filaments) and staple fibers, elastic filaments: non-elastic filaments: staple fibers (addition amount) = 1:1:7, elastic filaments are selected from spandex, Among them, spandex includes two parts, half of which is 40D, and the other half is 70D; the non-elastic yarn is polyester, and the fiber is 50D; the short fiber is polyester, and the fiber is 1.5D. During the spinning process, the spindle speed of the spinning machine is 13000r / min, the speed of the winder is 1000r / min, and all the other process designs are identical to embodiment 1.

[0053] The bobbin yarn formed by the above process, that is, the three-core yarn is 16S polyester (50D polyester+40D)+70D yarn, and the three-core yarn is used as the weft yarn. The fabric weave of the gray fabric is 76x48, and the warp yarn is 16S polyester.

...

Embodiment 3

[0063] Embodiment 3: 16S cotton viscose (40D nylon+40D)+7D yarn

[0064] In this example, the raw materials are elastic yarn (long yarn), non-elastic yarn (long yarn) and staple fiber, elastic yarn: non-elastic yarn: staple fiber (addition amount) = 2:1:7, elastic yarn is spandex, Among them, spandex includes two parts, half of which is 40D, and the other half is 70D; the non-elastic yarn is polyester, and the fiber is 40D; the short fiber is viscose blended fiber, and the fiber is 1.5D. Be 13000r / min, the speed of a vehicle of winder is 1200r / min, and all the other technological designs are identical with embodiment 1.

[0065] The bobbin yarn formed by the above process, that is, the three-core yarn is 16S cotton viscose (40D nylon + 40D) + 7D yarn, and the three-core yarn is used as the weft yarn. The gray fabric weave is 155x55, and the warp yarn is 40s cotton.

[0066] After the woven fabric has passed through drawing, sizing, drafting, weaving, and after dyeing and fini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elasticity | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com