Underwater electromagnetic separation electric connector

A technology of electromagnetic separation and electrical connectors, which is applied in the direction of connection and connection of parts and circuits of devices, can solve the problems of increasing equipment space occupancy, reducing equipment use efficiency, and being unfavorable for equipment maintenance, so as to reduce the overall occupancy Space, reduce maintenance costs, improve the effect of repeated utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

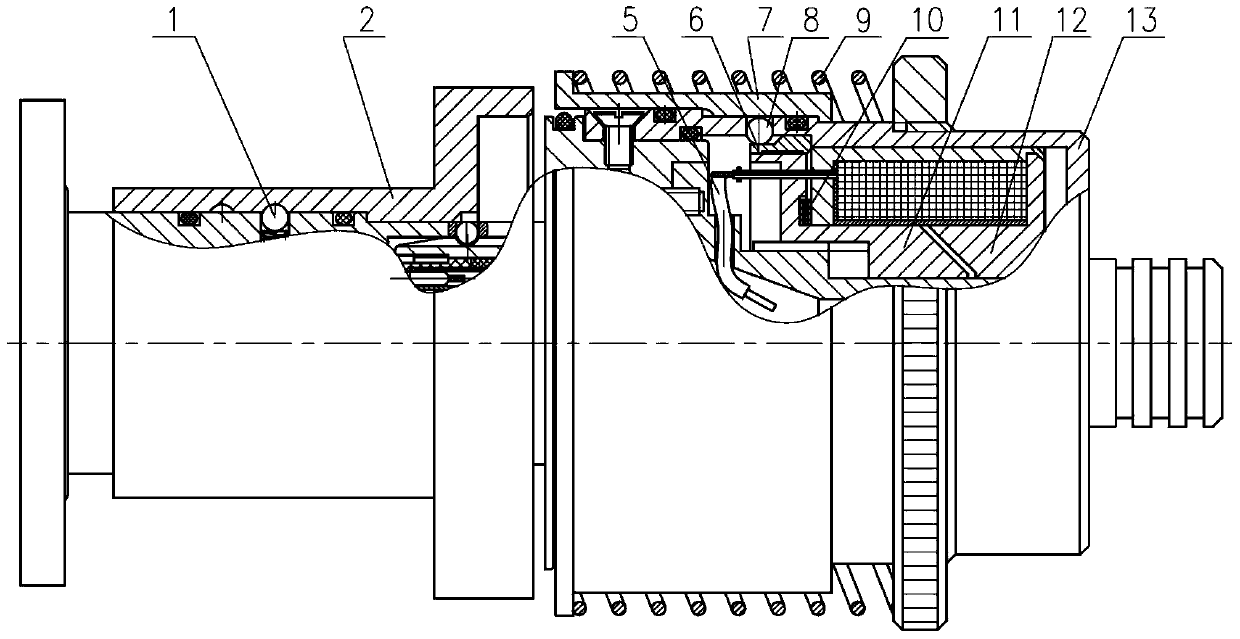

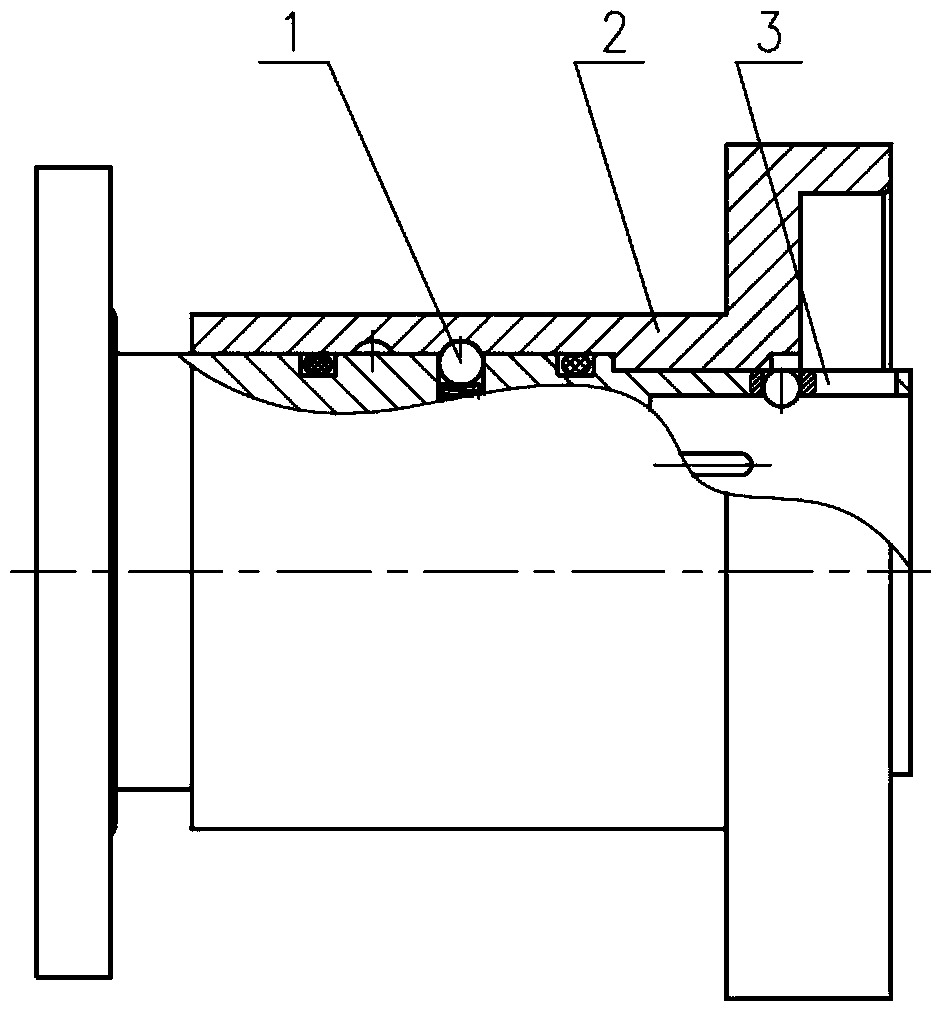

[0016] Such as figure 1 , 2 , 3, the underwater electromagnetic separation electrical connector of the present invention includes two parts, a plug and a socket. The socket includes a socket limit steel ball 1, an unlocking sleeve 2 and a socket body 3. The unlocking sleeve 2 is set on the outside of the socket body 3, and there is a clearance fit between the two. The steel ball 1 is located in the blind hole of the socket body 3 and closely fits with the inner surface of the unlocking sleeve 2.

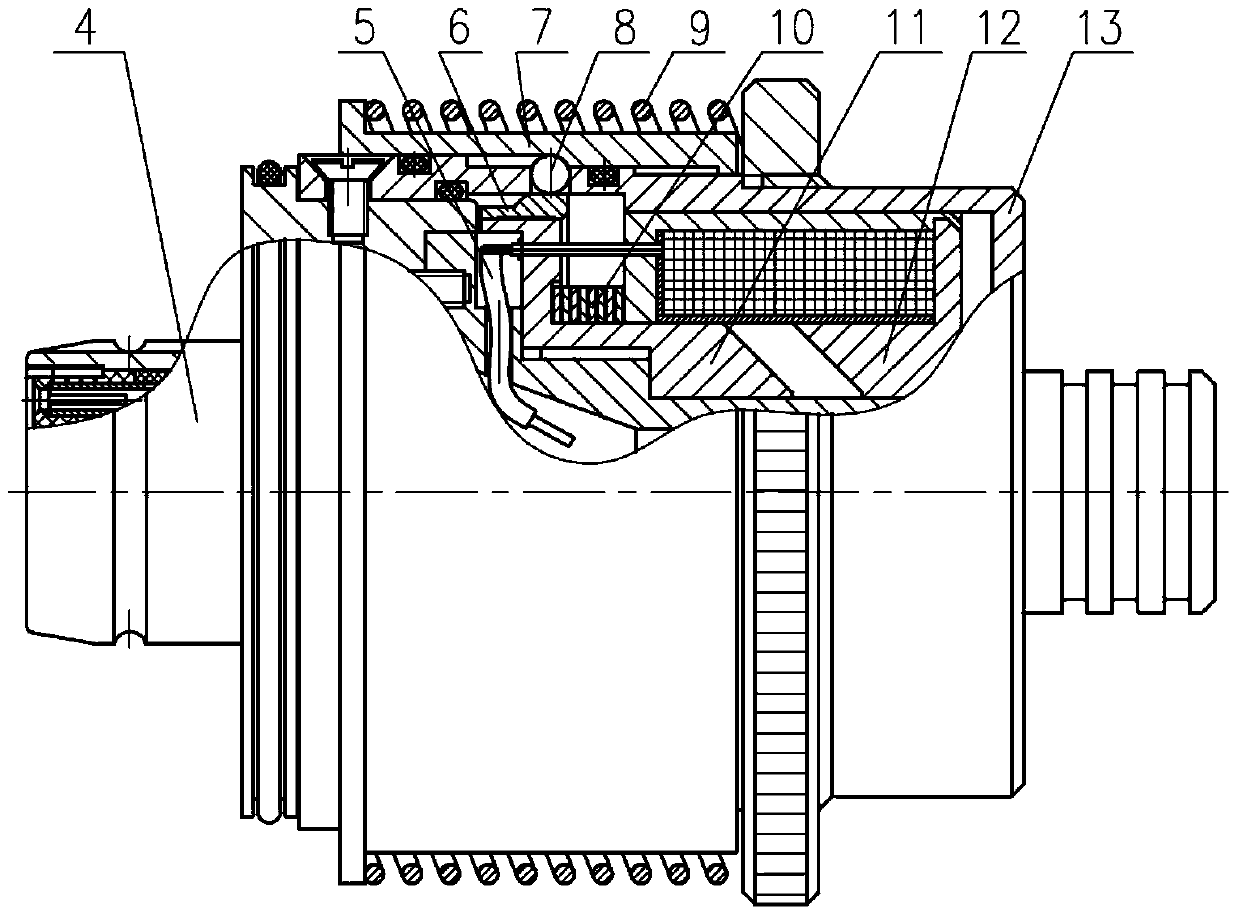

[0017] The plug includes a plug body 4, an electrical signal receiving end 5, a limit collar 6, a collision sleeve 7, a plug limit steel ball 8, a spring 9, a reed set 10, a movable electromagnet 11, a fixed electromagnet 12 and a tail cover 13 . The limit collar 6 is set on the outer circle of the movable electromagnet 11, and the two are glued and fixed together, and the electric signal receiving end 5, the limit collar 6, the reed group 10, the movable electromagnet 11 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com