Resistance welding process of fluid reservoir of compressor

A technology of resistance welding and liquid storage tank, which is applied in the direction of resistance welding equipment, curved surface seam welding, roller electrode welding, etc., which can solve the problems of high energy consumption of welding process, high cost of welding seam, large work site, etc., and achieve saving The effect of welding materials, reducing welding costs, and reducing site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below.

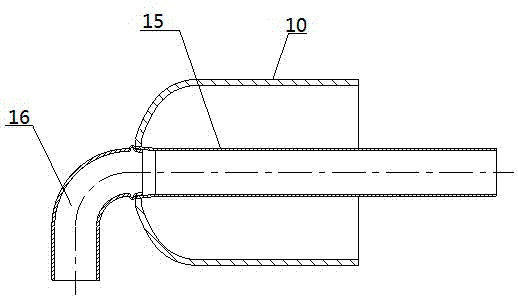

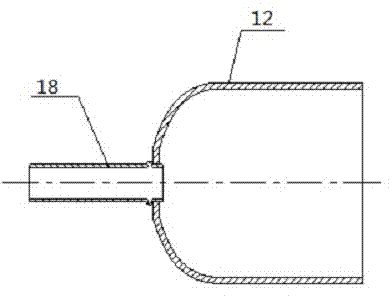

[0021] The embodiment of the present invention is to weld the upper shell of the air conditioner compressor liquid storage tank and its attached external butt joint copper pipe and internal butt joint steel pipe, abandoning the traditional high-cost and high-pollution brazing process in the furnace, and using resistance welding The process method replaces the traditional furnace brazing process, making the welding manufacturing process more environmentally friendly and cost-effective. refer to figure 1 As shown, the embodiment of the present invention mainly redesigns the welding structure of the upper casing of the liquid storage tank of the air conditioner, so that it has the feasibility of the resistance welding process, and discharges the copper pipe, the internal steel pipe, and the liquid storage tank from the upper casing of the liquid storage tank. The upper shell of the tank is firstly welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com