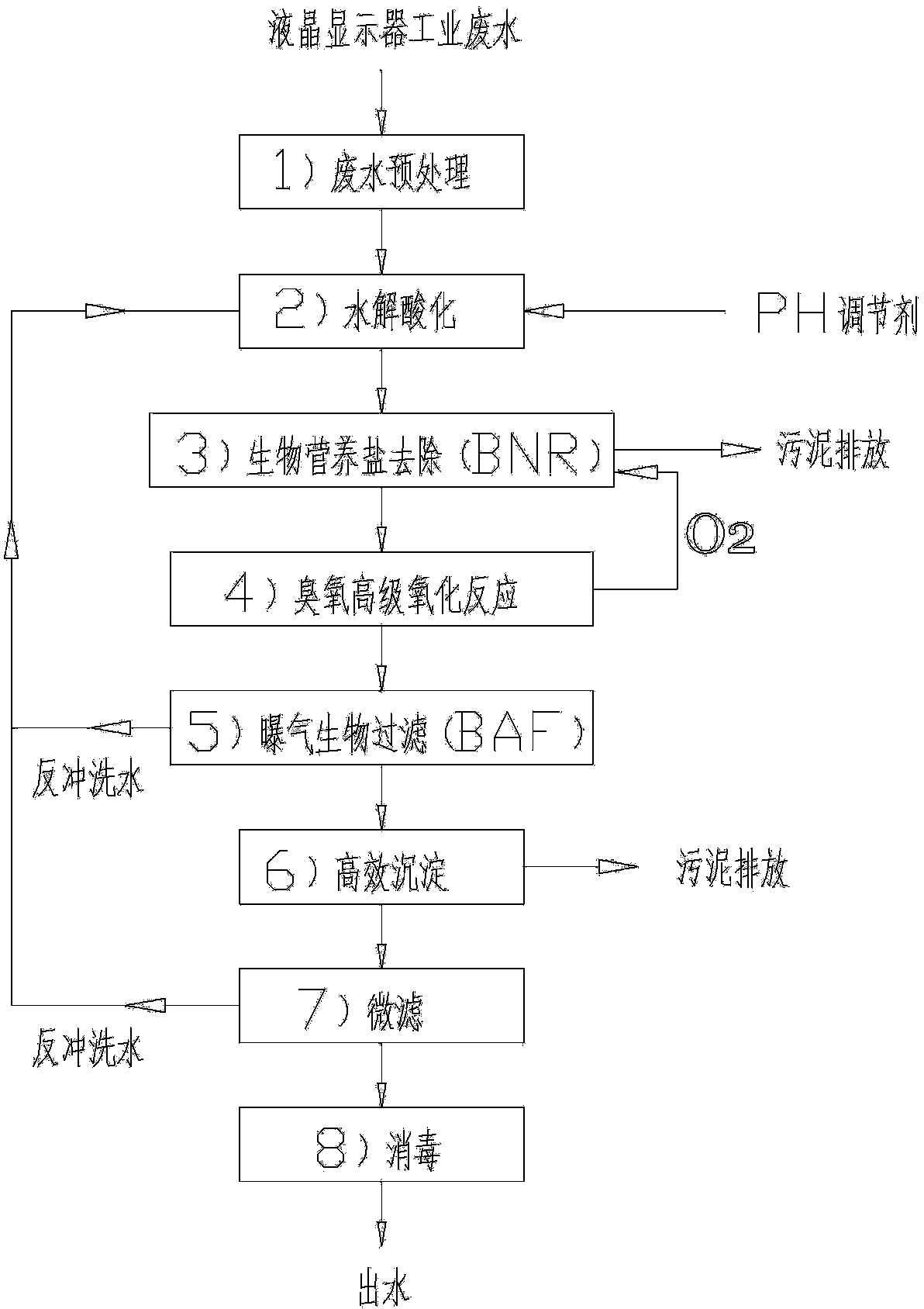

LCD (liquid crystal display) industrial wastewater advanced treatment technology

A liquid crystal display and industrial wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high concentration, difficult industrial wastewater treatment, and many types of pollutants , to achieve the effects of improving degradation efficiency, reducing energy consumption and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a certain LCD project, all kinds of production wastewater produced by various production processes are mixed and discharged after being classified and treated by the sewage treatment station in the factory. This embodiment is aimed at the treatment of the mixed discharge water.

[0038] A liquid crystal display industrial wastewater advanced treatment process, including equipment: fine grid 1, hydrolytic acidification tank 2, biological nutrient removal (BNR) unit 3, ozone advanced oxidation reactor 4, biological aerated filtration (BAF) tank 5 , high-efficiency sedimentation tank 6, post-microfiltration tank 7, chlorine dioxide disinfection tank 8, in which biological nutrient salt removal (BNR) unit 3 adopts sedimentation tank + microfiltration tank, which includes anaerobic / anoxic 1 / aerobic 1 / Anoxic 2 / aerobic 2 biochemical reaction tank, secondary sedimentation tank and pre-microfiltration.

[0039] The wastewater treatment steps of the present embodiment are as ...

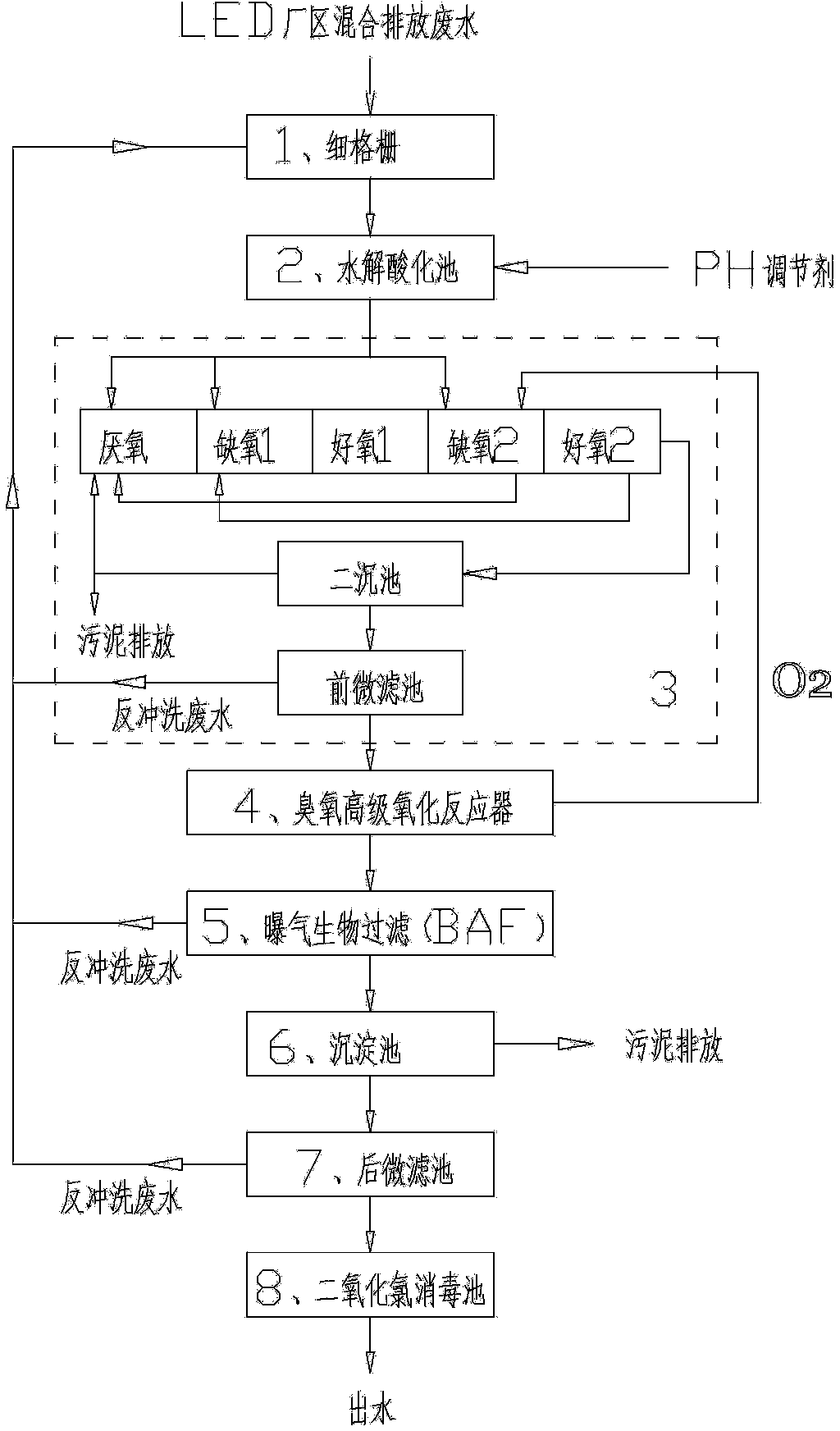

Embodiment 2

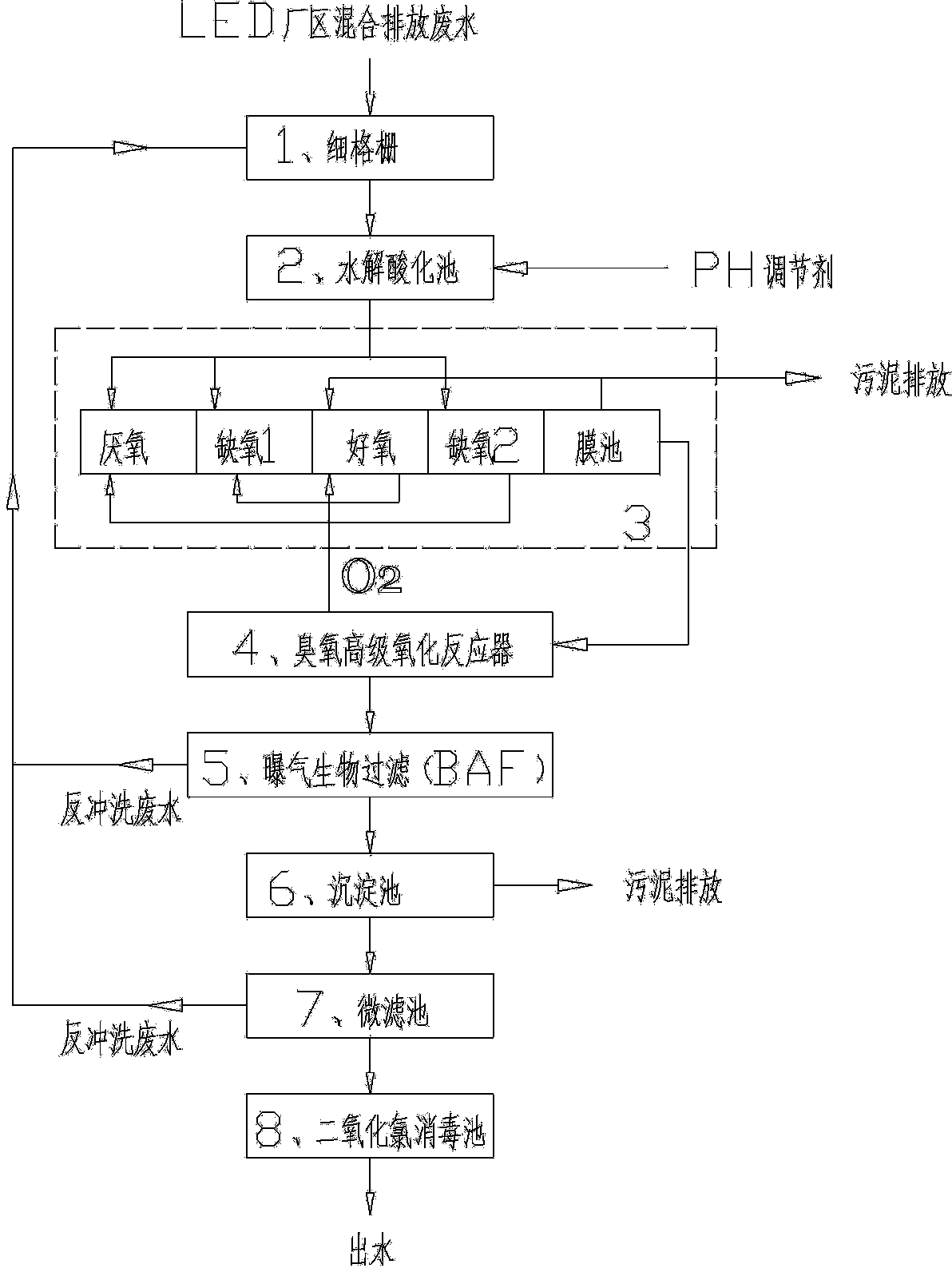

[0055] The waste water generated by each production process in the LCD factory area is mixed and discharged after classified treatment at each treatment station. image 3 The process shown treats this mixed effluent.

[0056] A liquid crystal display industrial wastewater advanced treatment process, including equipment: fine grid 1, hydrolytic acidification tank 2, biological nutrient removal (BNR) unit 3, ozone advanced oxidation reactor 4, biological aerated filtration (BAF) tank 5 , high-efficiency sedimentation tank 6, microfiltration tank 7, chlorine dioxide disinfection tank 8, in which biological nutrient salt removal (BNR) unit 3 adopts membrane tank, including anaerobic / anoxic 1 / aerobic / anoxic 2 / membrane pool .

[0057] The wastewater treatment steps of the present embodiment are as follows:

[0058] A liquid crystal display industrial wastewater advanced treatment process, comprising the following treatment steps:

[0059] 1) Pretreatment, the traditional water tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com