Environment-friendly humic acid containing water-soluble fertilizer and production method thereof

A production method and technology of humic acid are applied in fertilizer mixtures, fertilization devices, applications, etc., to achieve the effects of long use time, not easy precipitation, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

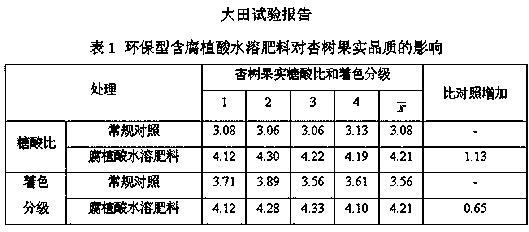

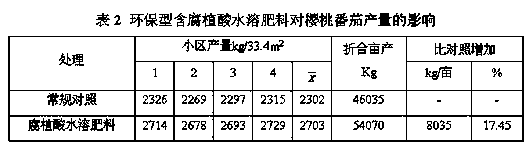

Examples

Embodiment 1

[0022] Mix 120~170kg of potassium humate containing 55~65% of humic acid with 350~400kg of demineralized water, keep the temperature at 70~80°C for 0.5 hours, and continue to add 60~100kg of dihydrogen phosphate in the finished product batching tank Potassium, 100~120kg potassium chloride, 50~90kg potassium carbonate, 10~20kg boric acid, 5~20kg γ-polyglutamic acid, 10~30kg rhamnolipid and 200~350kg urea, react at 55°C for 1.5 hours, During the pulping reaction, fully stir and dissolve 50~70kg hydroxyethyl cellulose with hot water at 75~85℃ in the liquid storage tank to obtain the suspension mother liquor, and finally mix the suspension mother liquor in the liquid storage tank with the finished product preparation tank The liquid is mixed and emulsified and ground for 3 hours under the action of the emulsification pump (the emulsification pump is a part of the finished product preparation tank), and then placed at room temperature to obtain dark brown, moderate viscosity, pH 7.6...

Embodiment 2

[0024] Mix 150~200kg of sodium humate containing 55~65% of humic acid with 300~380kg of demineralized water, keep the temperature at 70~80°C for 1 hour, and continue to add 100~130kg of dihydrogen phosphate in the finished product batching tank Potassium, 100~130kg potassium chloride, 30~70kg potassium carbonate, 8~15kg boric acid, 10~80kg γ-polyglutamic acid, 15~50kg rhamnolipid and 250~300kg urea, react at 55°C for 1.5 hours, During the pulping reaction, fully stir and dissolve 60~100kg hydroxyethyl cellulose with hot water at 75~85°C in the liquid storage tank to obtain the suspension mother liquor, and finally mix the suspension mother liquor in the liquid storage tank with the finished product preparation tank The liquid is mixed and emulsified and ground for 3.5 hours under the action of the emulsification pump (the emulsification pump is a part of the finished product preparation tank), and then placed at room temperature to obtain dark brown, moderate viscosity, pH 7.81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com