Nano optical waterproof glue and nano waterproof lamp employing same

A technology of nano optics and waterproof glue, which is applied in the fields of nano optics waterproof glue and nano waterproof lights, can solve problems such as aging, water leakage, elastic fatigue, etc., and achieve the effect of yellowing and aging solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The invention discloses a nano optical waterproof glue, which comprises 30 parts of chloropropylene oxide, 30 parts of nano-sized phenol methane, and 40 parts of nano-sized polyvinyl chloride in parts by weight. The nano-sized optical waterproof glue is obtained by mixing the above components evenly. The preparation method of the nano-sized phenolic methane is as follows: the phenolic methane is collided and rubbed with a nanosphere with a diameter of 400 nm for 11 hours; the preparation method of the nano-sized polyvinyl chloride is: the polyvinyl chloride is collided with a diameter of 400 nm Get it by rubbing for 11 hours.

Embodiment 2

[0018] The invention discloses a nano optical waterproof glue, which comprises 25 parts by weight of propylene oxide, 30 parts of nano-sized phenolic methane, and 45 parts of nano-sized polyvinyl chloride. The nano-sized optical waterproof glue is obtained by mixing the above components evenly. The preparation method of the nano-sized phenolic methane is as follows: the phenolic methane is collided and rubbed with a nanosphere with a diameter of 300 nm for 10 hours; the preparation method of the nano-sized polyvinyl chloride is: the polyvinyl chloride is collided with a diameter of 500 nm Get it after 12 hours of rubbing.

Embodiment 3

[0020] A nanometer optical waterproof glue, which comprises 30 parts by weight of propylene oxide, 35 parts of nanometer phenolmethane, and 35 parts of nanometer polyvinyl chloride. The nanometer optical waterproof glue is obtained by mixing the above components evenly. The preparation method of the nano-sized phenolic methane is as follows: the phenolic methane is collided and rubbed with a nanosphere with a diameter of 500 nm for 12 hours; the preparation method of the nano-sized polyvinyl chloride is: the polyvinyl chloride is collided with a diameter of 300 nm Get it after 10 hours of rubbing.

[0021] The penetration rate of the nano-optical waterproof glue prepared in the above examples is above 90%, and the refractive index is similar to that of water, so the glue can efficiently introduce light into the water.

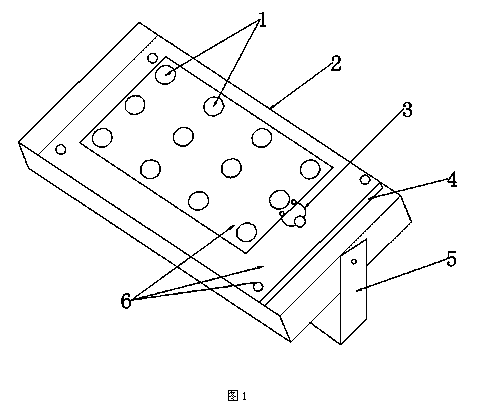

[0022] see figure 1 , a nano-waterproof lamp using the above-mentioned nano-optical waterproof glue, directly apply nano-optical waterproof glue 6 to the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com