Biodiesel nano-emulsion as well as preparation method and application thereof

A biodiesel and nanoemulsion technology, which is applied in chemical instruments and methods, petroleum industry, drilling compositions, etc., can solve the problems of difficult breakthroughs in key technologies, limitations, shortage of raw materials, etc., and achieve excellent lubricating effect and long-term stability. the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 40g of biodiesel, 4.4g of Span80, 5.6g of Tween80, and 50g of water prepared from waste oil by immobilized enzyme method, mix the biodiesel with the nonionic surfactant composed of Span80 and Tween80, add it to the reactor and heat To 60°C, under the condition of constant stirring, water was gradually added dropwise into the reactor at a rate of 3ml / min to make a mixed solution, the mixed solution was naturally cooled to room temperature, and the biodiesel nanoemulsion was obtained by standing at room temperature.

[0020] The performance of the prepared biodiesel nanoemulsion was evaluated according to the following methods:

[0021] 1. Long-term stability:

[0022] The biodiesel nanoemulsion prepared by the present invention is left to stand for half a year, and the appearance is observed. If the emulsion does not appear clear delamination, it shows that the biodiesel nanoemulsion has good long-term stability.

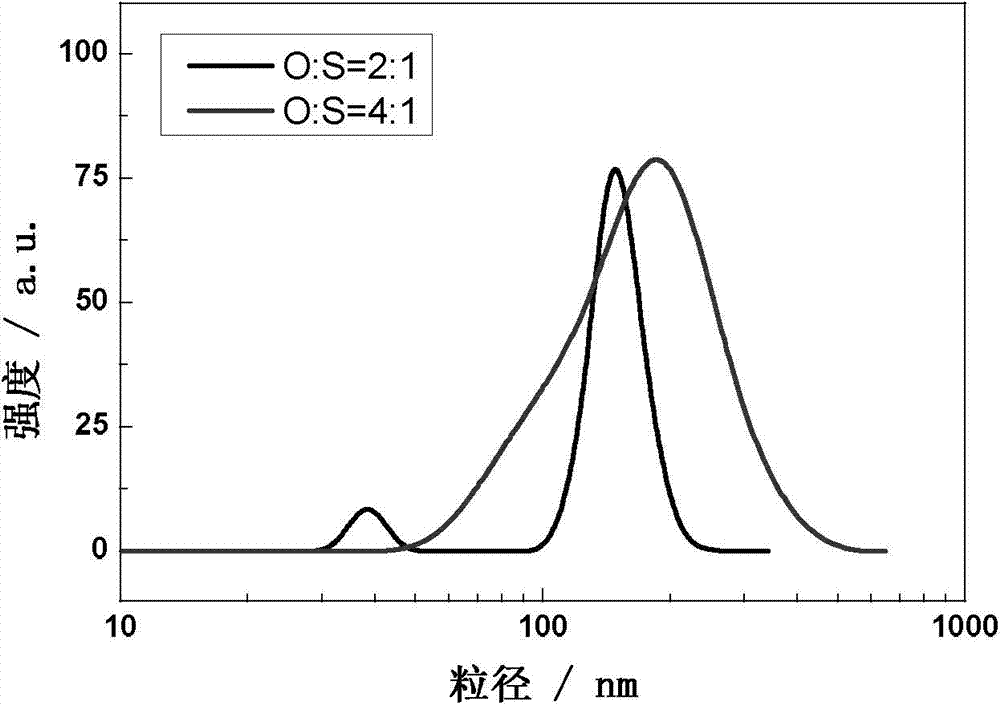

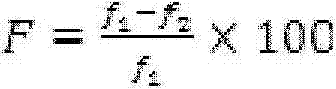

[0023] 2. Particle size distribution measurement:...

Embodiment 2

[0041] Weigh 13.3g of biodiesel produced from gutter oil by immobilized enzyme method, 2.68g of Span80, 4.02g of Tween80 and 80g of water. Mix biodiesel with non-ionic surfactants composed of Span80 and Tween80, add it into the reactor and heat it to 60°C, and gradually add water into the reactor dropwise at a rate of 3ml / min under constant stirring to prepare to form a mixed solution, naturally cool the mixed solution to room temperature, and let stand at room temperature to obtain biodiesel nanoemulsion.

[0042] Detected by the method described in Example 1, the results are shown in Table 2.

[0043] Table 2

[0044] Appearance

Embodiment 3

[0046] Weigh 5g of biodiesel produced from gutter oil by immobilized enzyme method, 2.2g of Span80, 2.8g of Tween80 and 90g of water. Mix the biodiesel with the non-ionic surfactant composed of Span80 and Tween80, add it into the reactor and heat it to 60°C, under the condition of constant stirring, water is gradually added dropwise into the reactor at a rate of 3ml / min, A mixed liquid is prepared, the mixed liquid is naturally cooled to room temperature, and left standing at room temperature to obtain the biodiesel nanoemulsion.

[0047] Detected by the method described in Example 1, the results are shown in Table 3.

[0048] table 3

[0049] Appearance

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com