High-frequency vibration aging system and method for eliminating residual stress of small-size component

A technology of high-frequency vibration and residual stress, applied in the field of small-sized components, to achieve the effects of reducing difficult clamping, eliminating residual stress, and small macroscopic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] With reference to accompanying drawing, further illustrate the present invention:

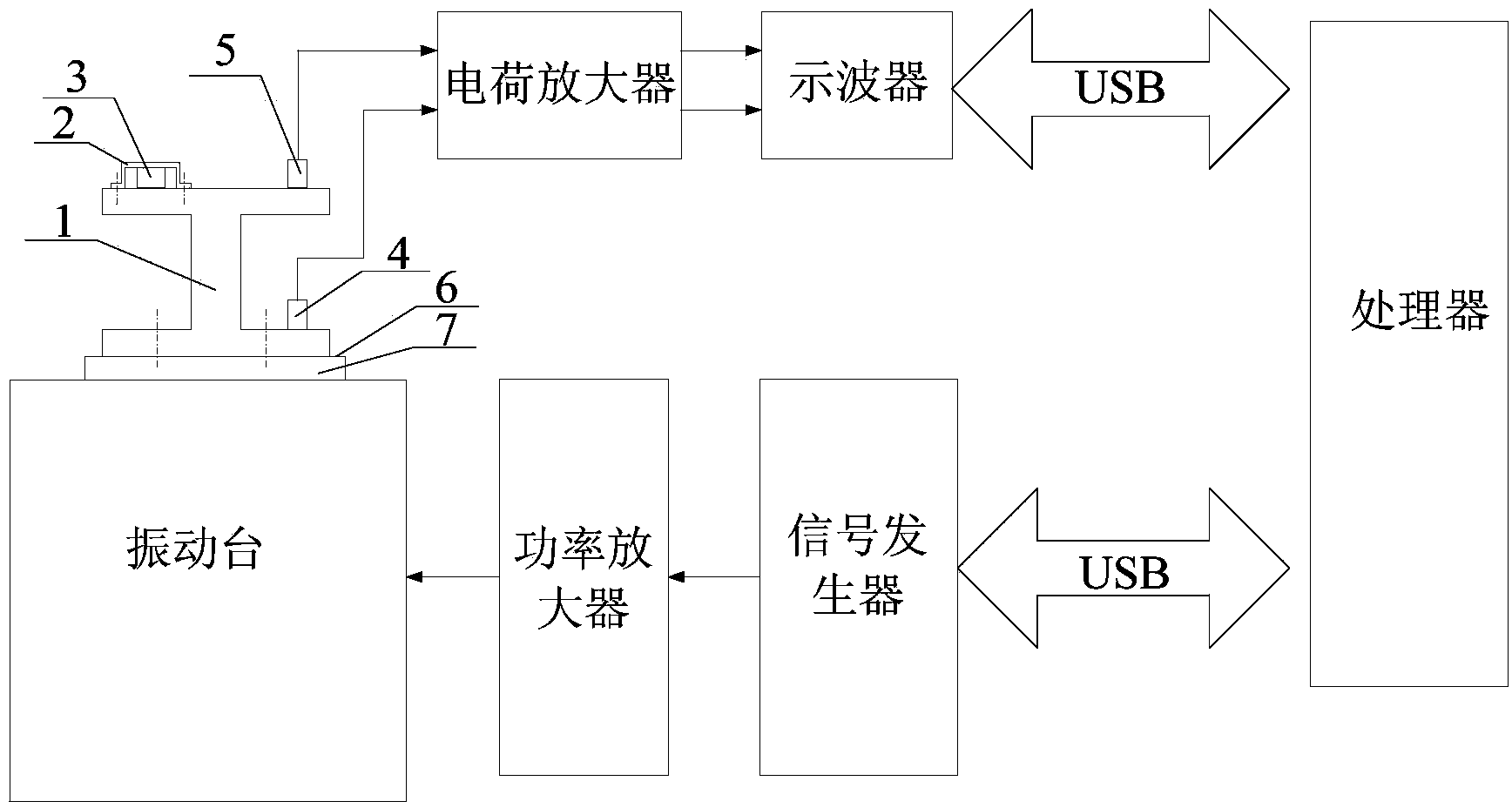

[0038]A high-frequency vibration aging system for eliminating the residual stress of small-sized components, including a signal generator, a power amplifier, a vibration table, a vibration level amplification device 1, a charge amplifier, an oscilloscope, and a processor; the processor controls the output amplitude of the signal generator and The sinusoidal excitation signal whose frequency can be independently and continuously adjusted; the sinusoidal excitation signal is input to the vibration table through the power amplifier;

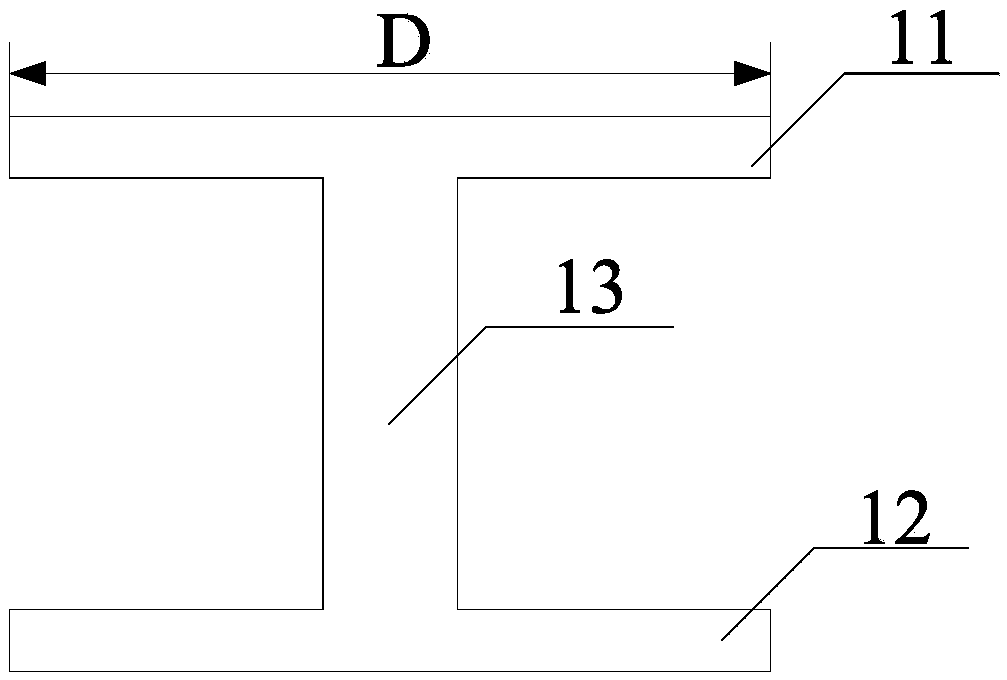

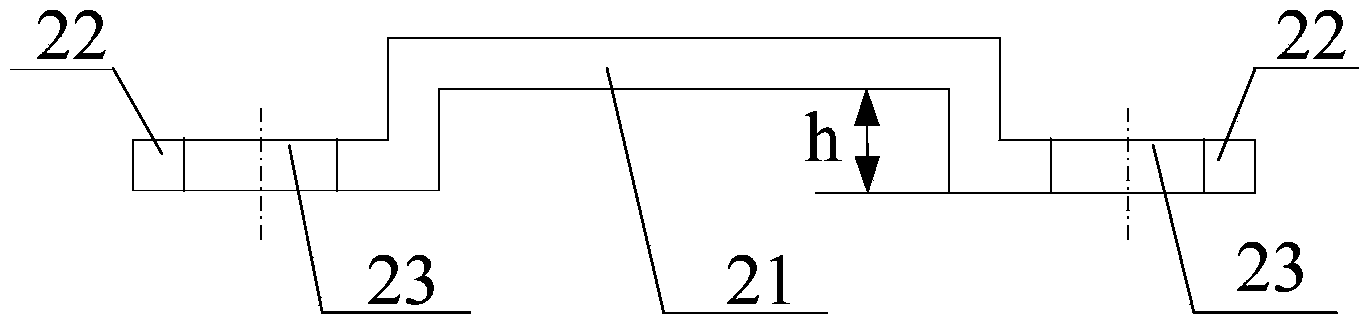

[0039] The vibration level amplifying device 1 is fixed on the excitation table surface 6 of the moving part 7 of the vibration table. The vibration level amplification device 1 includes an upper support platform 11, a lower chassis 12 fixed on the vibration excitation platform 6 and a connection between the upper support platform 11 and the lower chassis. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com