Electrolytic tinning liquid

An electro-tin plating solution and electro-tin technology, applied in the field of electro-tin plating, can solve problems such as equipment corrosion, empty plating product inflow, thickness fluctuation, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of electroplating tin bath of the present embodiment comprises following raw material components:

[0051] (A) stannous salt: stannous methanesulfonate, the concentration of stannous ion is 13g / L;

[0052] (B) Acid: methanesulfonic acid, the concentration is 50g / L;

[0053] (C) Surfactant: polyoxyethylene laurate ((C) 2 h 4 O) 10 ) ester, the concentration is 10g / L;

[0054] (D) Current dispersant: 2-ethylene glutaric acid, the concentration is 0.01g / L;

[0055] (E) Conductive salt: sodium phenolsulfonate, the concentration is 10g / L;

[0056] (F) pH regulator: KOH to adjust the pH to 3.2.

[0057] The electroplating process is as follows:

[0058] 1. Prepare the tin plating solution according to the ratio of the above raw materials;

[0059] 2. Filter, circulate and freeze the plating solution with a filter (filter element no more than 5 μm) and a freezer;

[0060] 3. Control the ratio of steel ball and plated parts;

[0061] 4. Rack plating and barrel ...

Embodiment 2-11

[0082] The raw material composition of the tin electroplating solution of embodiment 2-11 is as shown in table 1, and electroplating condition and test item are identical with embodiment 1, and result is as follows:

[0083] Table 1

[0084]

[0085]

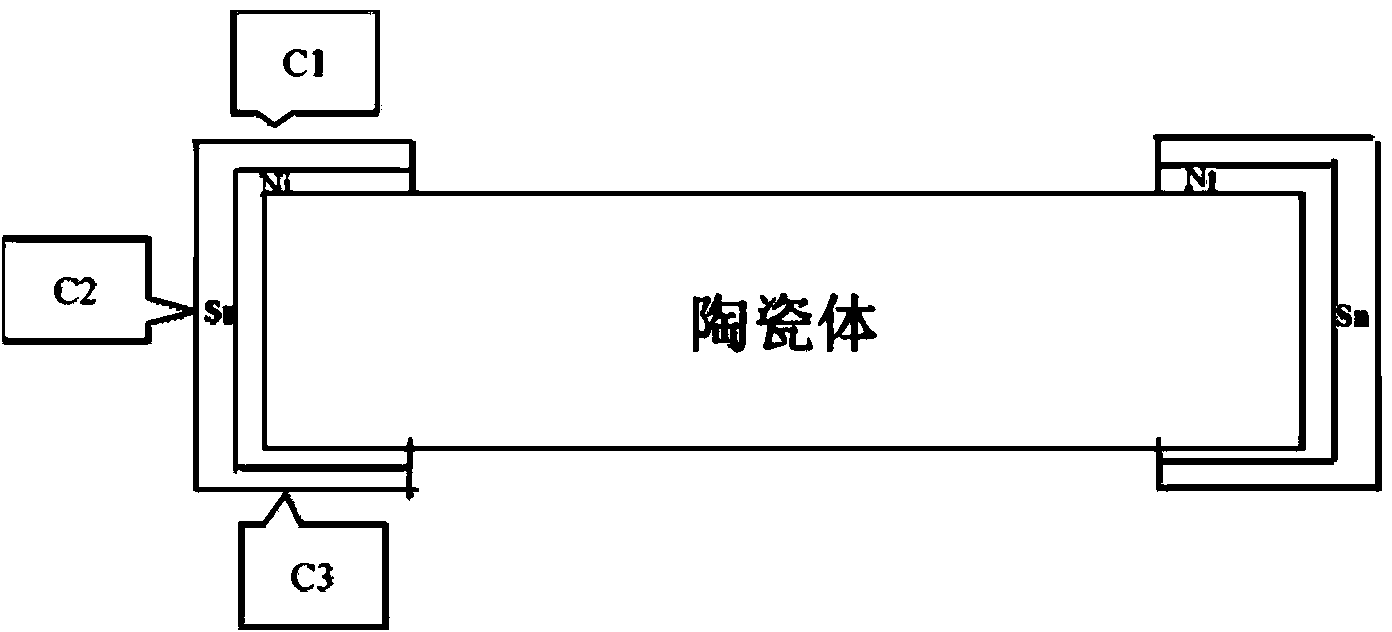

[0086] Δ indicates that the test result is good; X indicates that the test result is not good; the smaller the bonding rate, the higher the yield, generally not more than 10%; the HullCell test result indicates the length of bright and sub-bright areas, the length of bright and sub-bright The larger the range of the bright area, the wider the current window; the coating thickness range of 4-10 μm is qualified, and the closer the thickness of C1, C2, and C3 is, the better the throwing ability is; the voltage is lower than 1 / 2 of the current value. Low means less power consumption (voltage lower than 6V).

[0087] Through the comparison of Examples 1-11, it can be found that Examples 3 and 4 have lower voltage, the conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com