Vehicle magneto-rheological oil gas suspension damping valve

An oil-pneumatic suspension and magneto-rheological technology, applied in the direction of springs, shock absorbers, spring/shock absorbers, etc., can solve the problems of easy damage of sensors, lower viscosity, lower reliability of shock absorbers, etc., to facilitate heat dissipation , large damping force and small outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

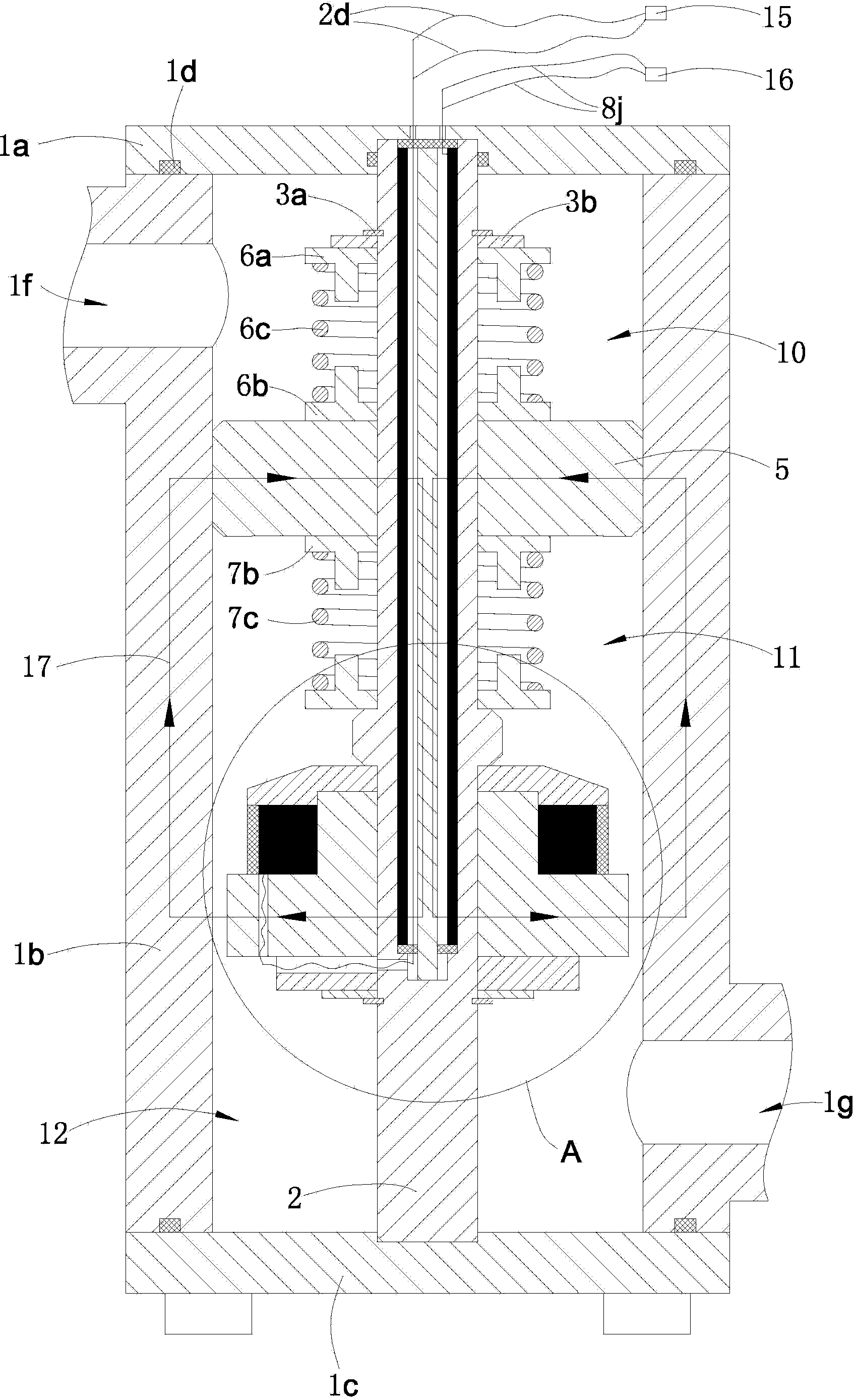

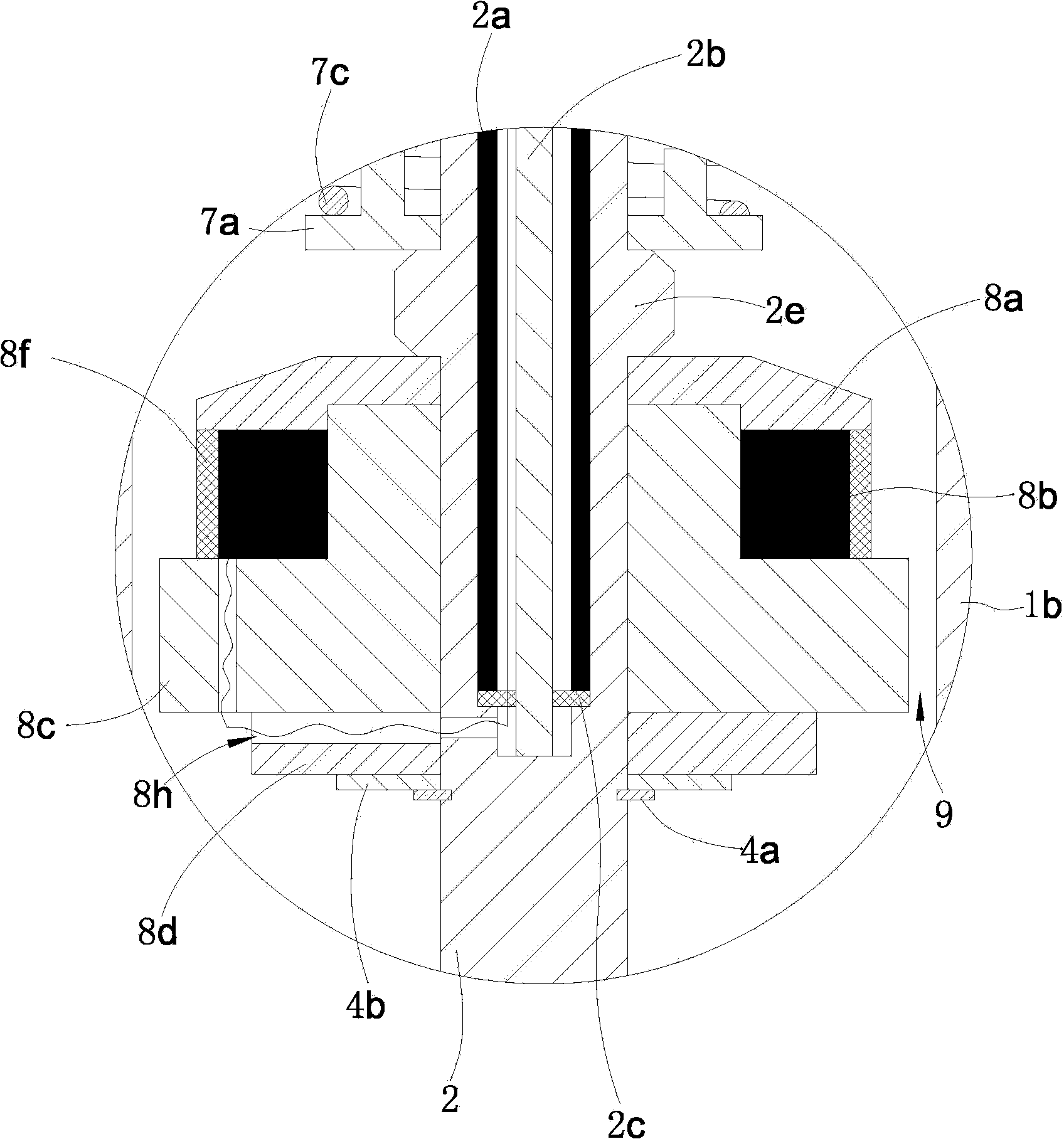

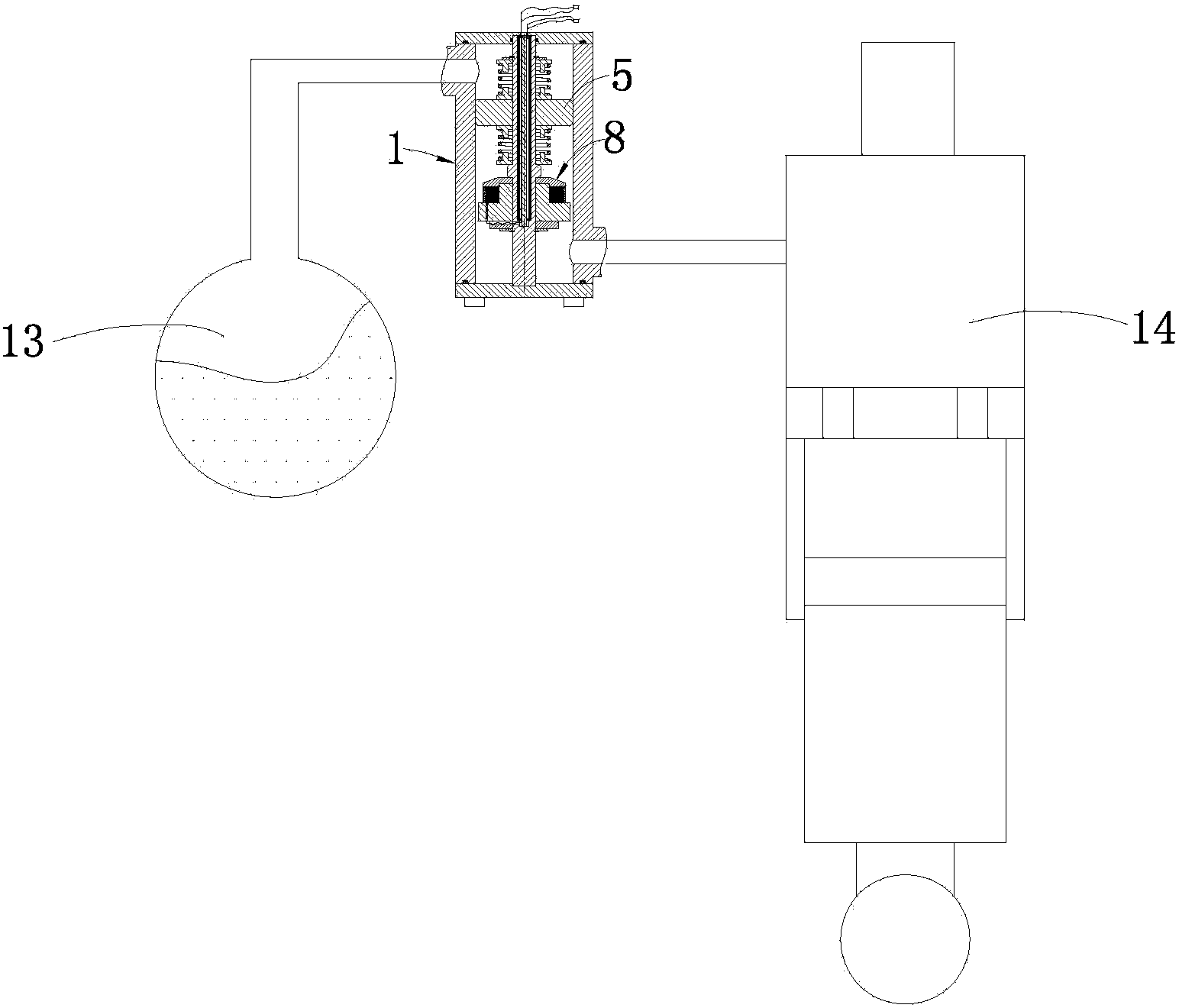

[0028] Such as Figures 1 to 2 shown

[0029] The damping valve includes a valve body 1, a mounting pipe 2, a floating piston 5, an upper limit assembly, a lower limit assembly, an upper fixing member, a fixed valve core 8 and a lower fixing member.

[0030] The valve body 1 includes an upper cover plate 1a, a sleeve 1b and a lower cover plate 1c, a sealing ring 1d is arranged between the upper cover plate 1a and the sleeve 1b, and a sealing ring 1d is also arranged between the lower cover plate 1c and the sleeve 1b , The upper cover 1a and the lower cover 1c are made of extremely low magnetic permeability materials; the sleeve 1b is made of high magnetic permeability materials.

[0031] An installation pipe 2 is fixed between the upper cover plate 1a and the lower cover plate 1c. An induction coil 2a and a winding rod 2b are arranged inside the installation pipe 2. The induction coil 2a is wound outside the winding rod 2b. The upper and lower ends of the induction coil 2a ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com