Birnessite type manganese dioxide nanosheet hydrogen sensor and preparation method thereof

A technology of manganese dioxide and birnessite is applied in the field of hydrogen sensors, which can solve the problems of high working temperature of the sensor, limited application range, low sensitivity, etc., and achieve the effects of low cost, stable response, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

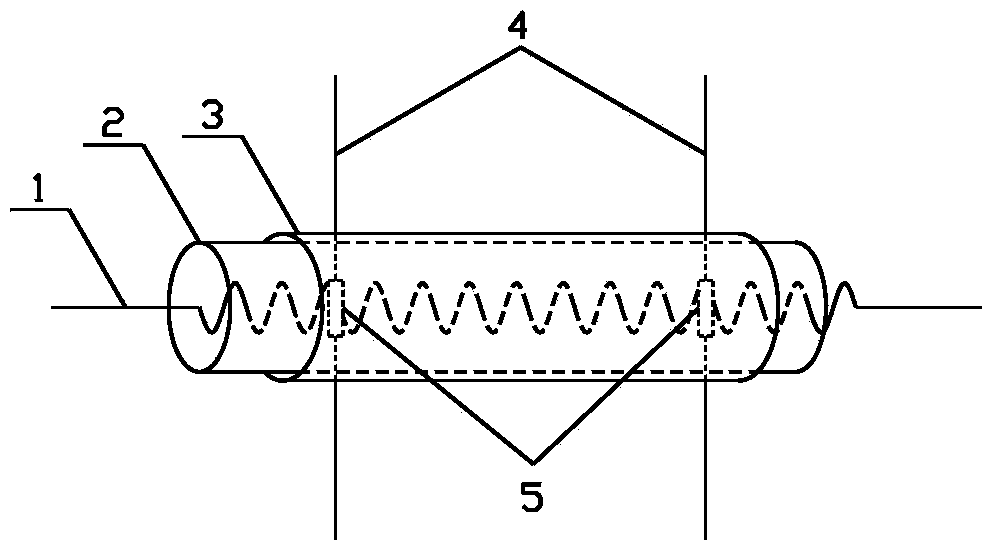

[0028] The present invention will be further described below in conjunction with accompanying drawing. Such as figure 1 As shown, this embodiment discloses a birnessite-type manganese dioxide nanosheet hydrogen sensor and a preparation method thereof. The hydrogen sensor structure includes a heating resistance wire and a ceramic tube 2, and the ceramic tube 2 is set on the heating resistance wire In addition, at least a pair of electrodes 4 are symmetrically arranged on the ceramic tube 2, and the electrodes 4 are provided with wires, and the wires are located in the ceramic tube 2, and the electrodes 4 and the ceramic tube 2 are coated with a gas-sensitive material layer, the gas-sensitive material layer is manganese dioxide nanosheet 3, so that a circuit is formed between the two electrodes 4 on the ceramic tube 2, the heating resistance wire is a Ni-Cr heating resistance wire 1, and the wire is a Pt wire wire 5.

[0029] Birnessite-type manganese dioxide nanosheet hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com