Batch process PI-PD control method for state space prediction function control optimization

A predictive function control, PI-PD technology, applied in the field of automation, can solve problems such as reducing batch production qualification rate, large overshoot and oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Take the temperature object control in the reboiler in a batch distillation column as an example:

[0067] The temperature object in the reboiler in the batch distillation column is a process of first-order inertia plus pure lag, and the adjustment method is to adjust the opening of the steam valve. The temperature in the reboiler is controlled by controlling the amount of steam entering.

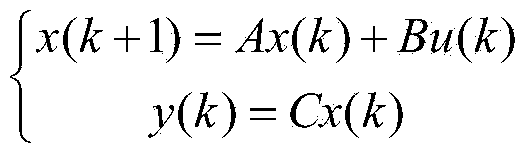

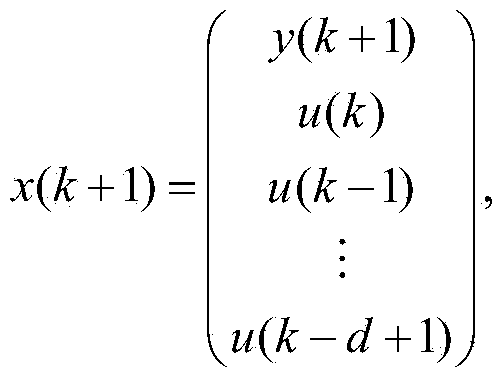

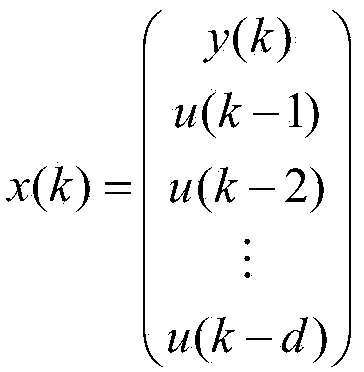

[0068] Step (1). Establish the state-space model of temperature object in the reboiler in the batch distillation tower, concrete method is:

[0069] a. Establish a real-time database of temperature objects in the reboiler, and establish a local prediction model through the real-time database. The specific method is: collect the real-time operation data of the temperature objects in the reboiler through the data acquisition device, and use the collected real-time process operation data as Data Driven Sample Collection in, Indicates the opening degree of the i-th group of steam va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com