Etchant composition for metal layers including copper and titanium

A technology of composition and etching solution, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as decomposed time, unstable time, and low etching rate, and achieve excellent etching performance, improved productivity, and Effect of Simplified Etching Step

Active Publication Date: 2016-07-27

DONGWOO FINE CHEM CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, in the process of etching copper-titanium bilayers, the problem is that different etchants with different compositions should be used for each layer

However, hydrogen peroxide-based etchant compositions have the disadvantage of being decomposed and unstable over time

And the shortcoming of potassium hydrogen persulfate type etchant composition is that its etch rate is low and can be unstable with time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 and comparative example 1

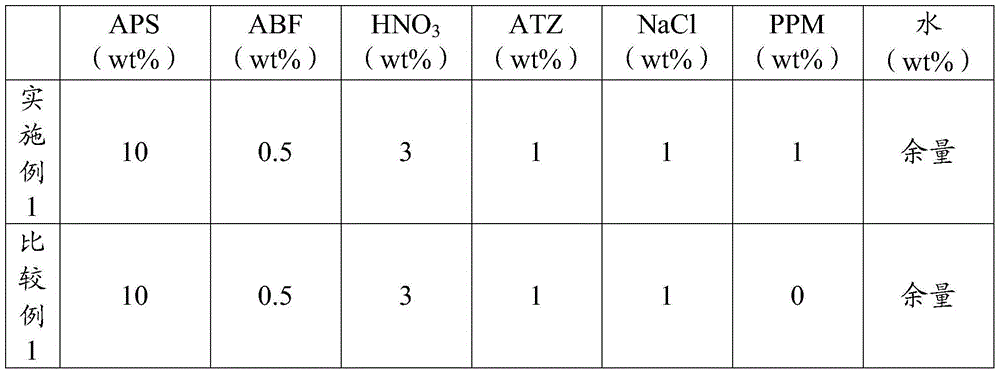

[0045] Embodiment 1 and comparative example 1: preparation of etching solution composition

[0046] 180 kg of each etching solution composition was prepared according to the ingredients and contents shown in Table 1 below.

[0047] [Table 1]

[0048]

[0049] Remarks: APS: ammonium persulfate; ABF: ammonium sodium hydrofluoride;

[0050] ATZ: 5-aminotetrazole; PPM: Potassium dihydrogen phosphate

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to an etchant liquid composition for a metal layer, the composition comprising: persulfate; a fluorine-containing compound; an inorganic acid; a ring-type amine compound; a compound containing chlorine; phosphate; and water. More particularly, the present invention relates to an etchant liquid composition for a metal layer, the composition comprising copper and titanium.

Description

technical field [0001] The present invention relates to an etchant composition for a metal layer comprising copper and titanium, and used for gate wiring, source / Drain wiring, gate electrodes, and source / drain electrodes. Background technique [0002] The process of forming metal wiring on substrates of semiconductor devices and flat panel display devices generally includes the following processes: forming a metal layer by sputtering; coating, exposing and developing a photoresist pattern on selected regions; and performing etching. Furthermore, the etching process is carried out before or after each individual step. [0003] The etching process means a process of patterning a metal layer using a photoresist as a mask, and generally includes a dry etching process using plasma or a wet etching process using an etching solution. [0004] In recent years, the resistance of metal wiring in semiconductor devices or flat panel display devices has become a major concern. Since ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/18C23F1/44C23F1/02

CPCC23F1/02C23F1/18C23F1/26C23F1/44H01L21/32134

Inventor 朴英哲李昔准姜京敏张尚勋

Owner DONGWOO FINE CHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com