Copper and titanium composition for metal layer etching solution

A technology of composition and etching solution, applied in electrical components, circuits, semiconductor/solid-state device manufacturing, etc., can solve problems such as slow etching rate and unstable composition time, achieve fast etching rate, excellent etching performance, and simplify etching effect of steps

Inactive Publication Date: 2014-12-10

DONGWOO FINE CHEM CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the case of potassium persulfate-based etchant compositions, the etch rate is slow and the composition becomes unstable over time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 and comparative example 1

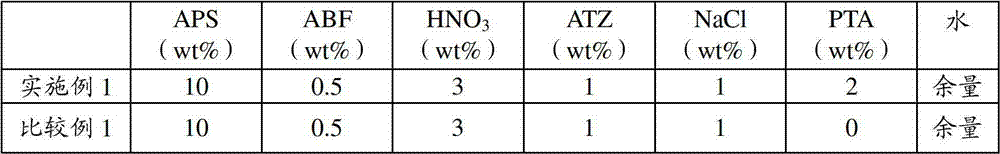

[0037] Embodiment 1 and comparative example 1: preparation of etching solution composition

[0038] 180 kg of an etching liquid composition was prepared using the amounts of components shown in Table 1 below.

[0039] [Table 1]

[0040]

[0041] *APS: Ammonium persulfate

[0042] ABF: Ammonium bifluoride

[0043] ATZ: 5-Aminotetrazole

[0044] PTA: p-toluenesulfonic acid

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a copper and titanium composition for a metal layer etching solution comprising the following, based on the total weight of the composition: 5 to 20 wt % of persulfate; 0.01 to 2 wt % of a fluorine compound; 1-10 wt % of an additive containing one or more acids selected from inorganic acids, salts of inorganic acids, and a mixture thereof; 0.3 to 5 wt % of a cyclic amine compound; 0.1 to 5 wt % of a chlorine compound; 0.1 to 5 wt % of a p-toluene sulfonic acid; and with the remainder being water.

Description

technical field [0001] The present invention relates to an etchant composition for a metal layer containing copper and titanium, the etchant composition is used for gate, source / drain wiring, and electrodes of semiconductor devices and flat panel displays, especially for Electrode of a thin film transistor (TFT). Background technique [0002] In semiconductor devices and flat panel displays, the process of forming metal wiring on a substrate generally includes forming a metal layer by sputtering, coating photoresist, forming photoresist on selected regions by exposure and development, and etching. Furthermore, washing steps are performed before or after each individual step. The etching step leaves the metal layer on selected areas using the photoresist as a mask, and typically includes dry etching using plasma or wet etching using an etchant. [0003] For semiconductor devices and flat panel displays, especially TFTs, the gate and source / drain array wiring consists of a m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23F1/18C23F1/30H01L21/205

CPCH01L21/32134C23F1/18C23F1/26C23F1/02C23F1/10C23F1/14C23F1/16C23F1/30H01L21/306H01L21/2855

Inventor 林玟基权五柄李喻珍刘仁浩

Owner DONGWOO FINE CHEM CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com