Rotational connection method of rotational inserting structures of filter cylinders of water purifier, and closed filter cylinder

A water purifier and filter cartridge technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems affecting the popularization of water purifiers, and achieve the effects of light weight, stable assembly quality and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

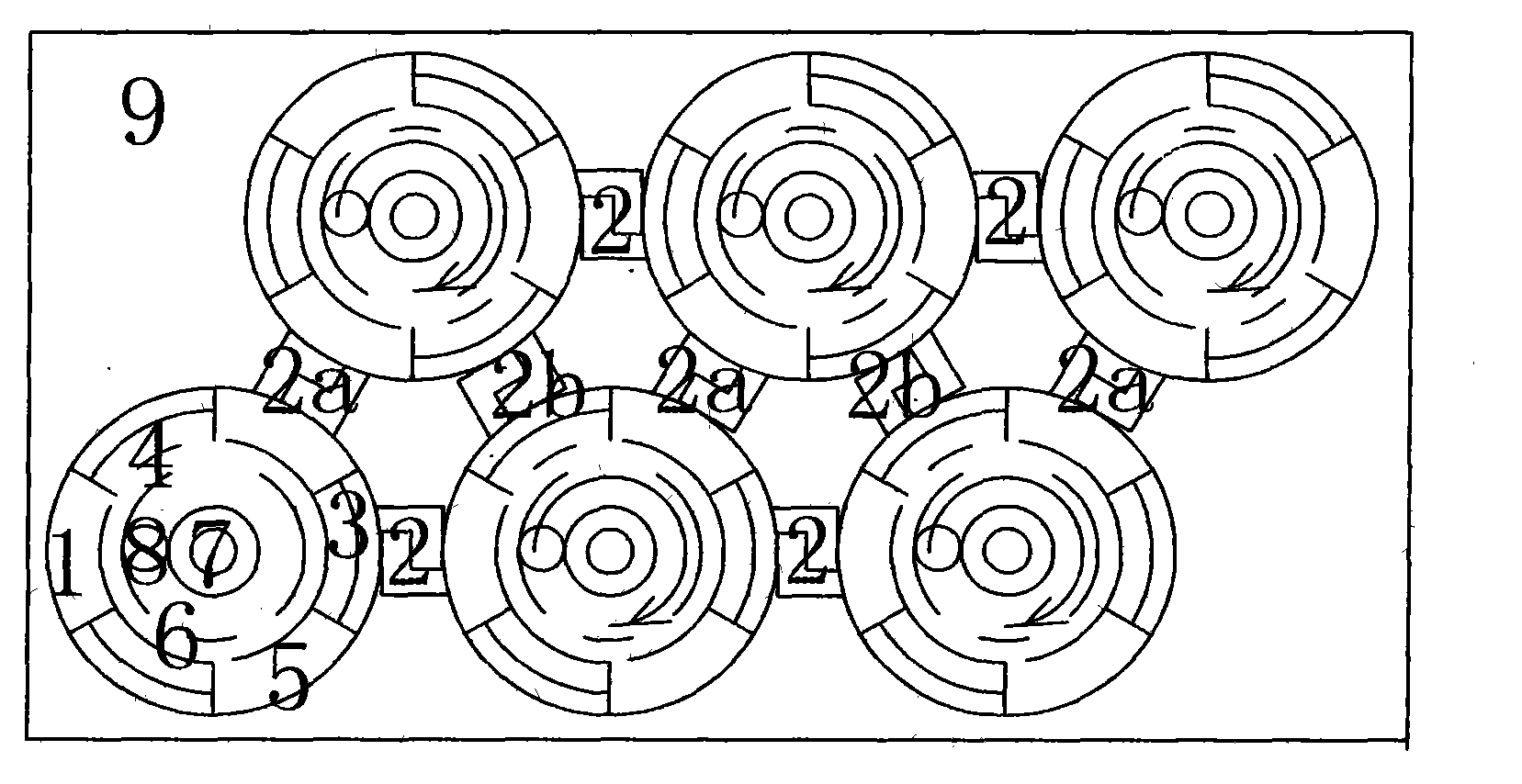

[0029] Example 1, figure 1 is a schematic diagram of Example 1.

[0030] The six individual filter cartridges 1 of the present invention are arranged in a double-row staggered arrangement, and the individual filter cartridges 1 are arranged in an equilateral triangle. On the base 9 corresponding to the position of each individual filter cartridge 1, an outwardly protruding and suspended arc-shaped radially fixed thread mouth 4 is provided. The angle corresponding to the arc-shaped radial fixed mouth 4 is 60°, and a notch 5 with a corresponding angle of 60° is provided between two adjacent arc-shaped radial fixed mouths 4 . The individual filter cartridges 1 are screwed and fitted with each other at four angles of 0°, 60°, 120° and 180° in turn. Each filter cartridge 1 is provided with screw-in structures 2, 2a, 2b on the outer circumference of the cylinder wall, and the corresponding angles of the lower arc-shaped radial tooth buckles 3, and the corresponding angles of the g...

Embodiment 2

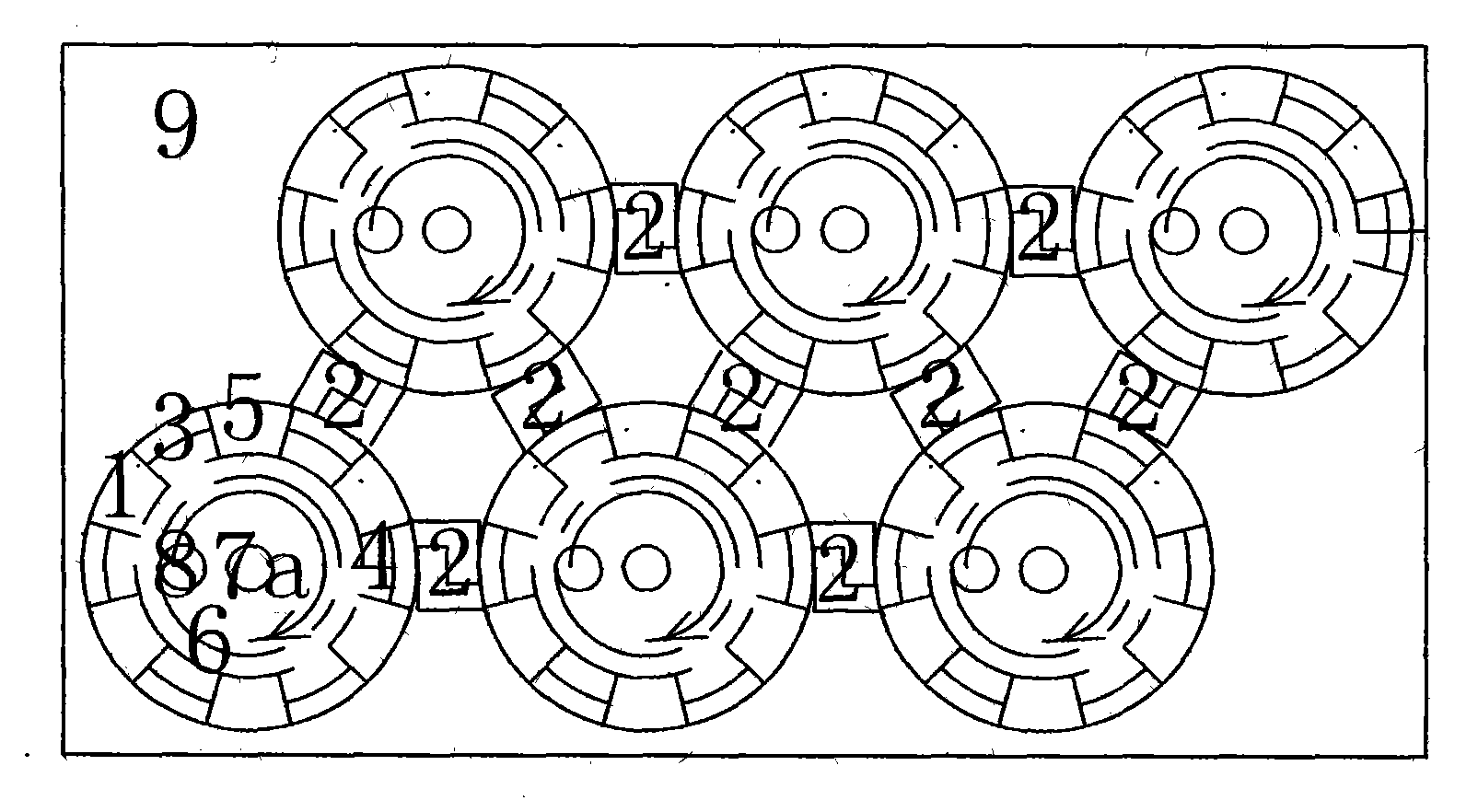

[0038] Example 2. On the basis of Example 1, the respective screw-in structures 2 of the six individual filter cartridges 1 are set at the same height and adjacently spaced by 60°; each filter cartridge 1 is provided with six inwardly protruding arc-shaped diameter To buckle 3, its corresponding angle is 30 °. The outwardly protruding and suspended arc-shaped radially fixed tooth buttons 4 provided on the corresponding base 9 have a corresponding angle of 30°. The angle corresponding to the gap 5 between the two arc-shaped radially fixed tooth buttons 4 is also 30°. Each filter cartridge 1 arc-shaped radial tooth buckle 3 is sequentially inserted into the gap 5 between the arc-shaped radial fixed tooth buckles 4 and rotated 30° in the same direction, and contacts with the machine base 9 arc-shaped radial fixed tooth buckles 4 up and down , Rotary fit. At the same time, two adjacent filter cartridges 1 are plugged and fitted with each other along the rotation tangent directi...

Embodiment 3

[0045] Embodiment 3, on the basis of Embodiments 1 and 2, the arc-shaped radial tooth button 3 at the lower part of the filter cartridge 1 is changed to the same outward screwing structure as the upper screwing structure 2, which is screwed and fitted along the tangential direction of rotation 2. Each filter cartridge 1 is inserted and matched with each other along the respective tangential directions through the upper and lower sets of screw-in structures on the outer peripheral surface of the cylinder wall to form the connection structure of the upper and lower parts of the filter cartridge. The machine base 9 corresponding to each filter cartridge 1 is connected with the cylinder body 1 through standard parts to form an integral body, and the inner cavity of the filter cartridge 1 and the machine base 9 form a conjoined sealed water channel through a seal; the machine base 9 is provided with a corresponding The water outlets of the water passages are respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com