Chrome oxide catalyst as well as preparation and application thereof

A catalyst and chromium oxide technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low efficiency of NO treatment technology, high risk of transportation and use , high manufacturing cost of strong oxidants, etc., to achieve long-term stable reaction activity, high conversion rate, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

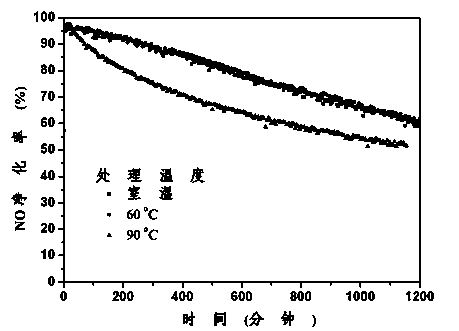

[0020] The chromium oxide catalyst was prepared by the deposition precipitation method. Weigh 10.0 g of chromium nitrate and dissolve it in 100 ml of deionized water. The stirring temperature was at ambient temperature. After adding 14 ml of precipitant ammonia water, the mixture was stirred for 6 h, filtered, washed, and dried at 100 ℃ for 12 h. Calcined at 300°C for 4 h to obtain a catalyst.

[0021] Weigh 1.0 g of the above-obtained catalyst at room temperature and start to pass reaction gas into it for activity test. The gas composition is 15 ppm NO, the rest is air, and the total flow rate is ≥720 ml / min (STP).

Embodiment 2

[0023] Compared with Example 1, the difference is that the stirring temperature is 60° C., and the amount of other materials and operating conditions are the same as Example 1.

Embodiment 3

[0025] Compared with Example 1, the difference is that the stirring temperature is 90°C, and the amount of other materials and operating conditions are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com