Nickel-based methanation catalyst promoted by in-situ growth of carbon nanotubes and preparation method thereof

A technology of in-situ growth of carbon nanotubes, applied in the petroleum industry, gas fuels, fuels, etc., can solve the problems of technology dependence, lack of mastery of synthesis gas methanation process, etc., and achieve good reactivity and good low-temperature methanation reactivity , The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

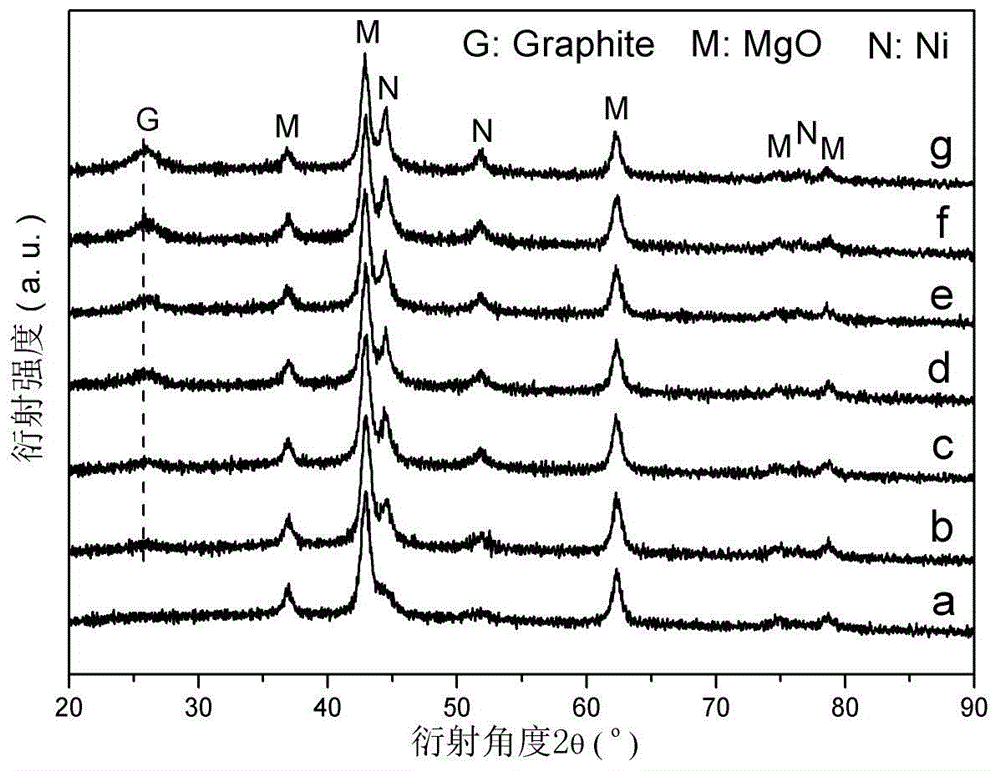

[0033] 1) 9.319g Ni(NO 3 ) 2 ·6H 2 O and 17.949g Mg(NO 3 ) 2 ·6H 2 O (purities are all AR pure) mixed, add 50mL deionized water to dissolve and prepare solution A; mix 9.330g NaOH and 6.181g NaHCO 3 (Purities are all AR pure) dissolved in 145mL deionized water to prepare solution B.

[0034] 2) At room temperature, add solution A and solution B dropwise into the reaction vessel at the same time, and keep the pH value of the mixture at 9.8-10.2 by controlling the drop rate of solution A and solution B under the condition of constant stirring, and drop solution A After the addition, use solution B to adjust the pH of the precipitation solution to 10. Place the precipitate in an oil bath at 363K for 12 hours, filter the obtained precipitate, and wash repeatedly for 3 to 4 times until the filtrate is neutral, then dry it in a 383K oven for 12 hours, and roast it in an air atmosphere of 723K for 5 hours to obtain Ni / MgO catalyst precursor.

[0035] 3) The catalyst precursor...

Embodiment 2

[0038] 1) Same as step 1) in Example 1.

[0039] 2) Same as step 2) in Example 1.

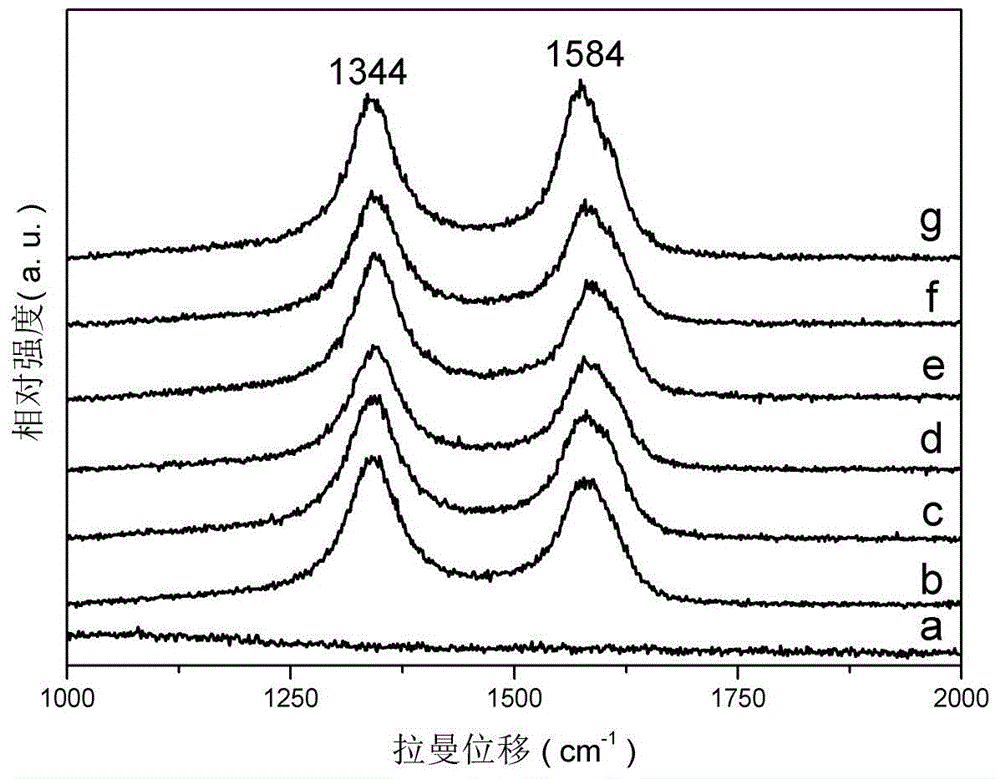

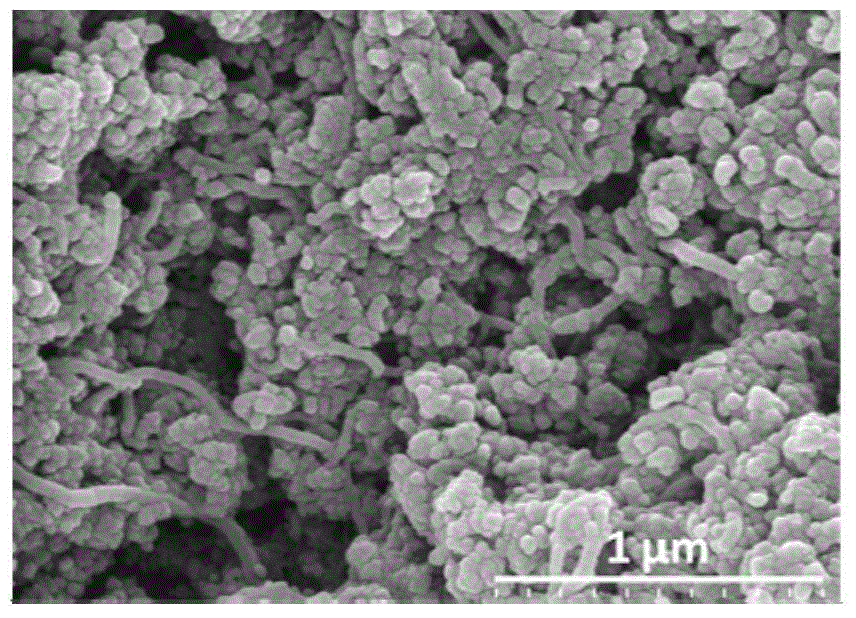

[0040] 3) The catalyst precursor is pressed into tablets and sieved to 40-80 mesh, the dosage is 100 mg, and mixed with 500 mg of quartz sand of the same mesh and diluted in the reactor, under normal pressure of 5% H 2 / Ar (volume percent) airflow (flow rate: 30mL / min) in 5K / min programmed temperature to 873K for 5h reduction to obtain the reduced nickel catalyst. Switch the gas flow to high-purity CO (99.9%) at 873K for 7.5 minutes with a space velocity of 18000mL STP h -1 · g-cat -1 , switch to 5%H 2 / Ar (flow rate 30mL / min), then lower the temperature to 823K for 2h to remove impurity carbon, and finally lower to 473K for evaluation. The catalyst obtained at this time is a catalyst for in-situ growth of carbon nanotubes, and the mass percentages of each component in the catalyst are: carbon nanotubes 16.4%; Ni 33.4%, and the balance is MgO.

[0041] The catalyst activity evaluation re...

Embodiment 3

[0043] 1) Same as step 1) in Example 1.

[0044] 2) Same as step 2) in Example 1.

[0045] 3) The catalyst precursor is pressed into tablets and sieved to 40-80 mesh, the dosage is 100 mg, and mixed with 500 mg of quartz sand of the same mesh and diluted in the reactor, under normal pressure of 5% H 2 / Ar (volume percent) airflow (flow rate: 30mL / min) in 5K / min programmed temperature to 873K for 5h reduction to obtain the reduced nickel catalyst. Switch the gas flow to high-purity CO (99.9%) at 873K for 10 minutes with a space velocity of 18000mL STP h -1 · g-cat -1 , switch to 5%H 2 / Ar (flow rate 30mL / min), then lower the temperature to 823K for 2h to remove impurity carbon, and finally lower to 473K for evaluation. The catalyst obtained at this time is the catalyst for growing carbon nanotubes in situ, and the mass percentages of the components in the catalyst are: carbon nanotubes 22.2%, Ni 31.1%, and the balance MgO.

[0046] The catalyst activity evaluation result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com