The preparation method of z-1-halo-3,3,3-trifluoropropene

A trifluoropropene, Z-1- technology, applied in the preparation of halogenated hydrocarbons, halogen substitution preparation, organic chemical methods, etc., to achieve the effects of high single-pass single rate, long service life and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

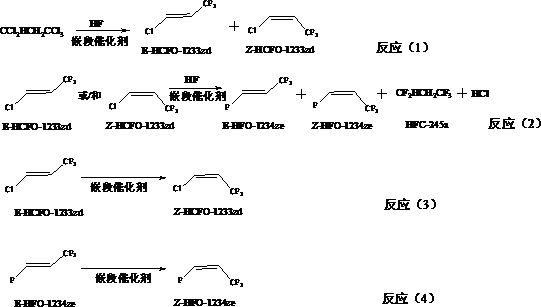

Method used

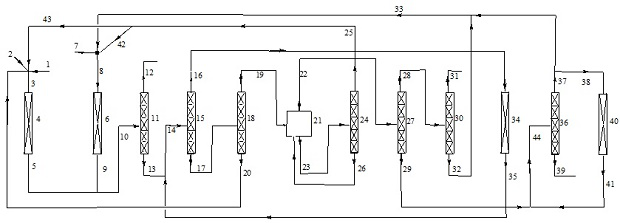

Image

Examples

Embodiment 1

[0052] Preparation of block catalyst: (1) Dissolve tungsten trichloride in water, then dropwise add 10% by mass ammonia water to completely precipitate metal ions, adjust the pH value to 7.0-9.0, and make it fully precipitate under stirring conditions , aged for 24 hours, filtered the formed slurry, then dried at 150°C for 18 hours, pulverized the solid, and pressed into shape to obtain a carrier precursor; the obtained carrier precursor was roasted at 400°C under a nitrogen atmosphere After 18 hours, it was activated at 300°C for 18 hours with a mixed gas consisting of hydrogen fluoride and nitrogen with a molar ratio of 1:2 to obtain a carrier, which was confirmed to be tungsten oxyfluoride by XPS detection; (2) in dry, high-purity In nitrogen or helium or argon atmosphere, according to 20% SbF in block catalyst 5 Composed of 80% tungsten oxyfluoride mass percentage content, the precursor of the active component SbCl 5 Coating on tungsten oxyfluoride to obtain a catalyst pr...

Embodiment 2

[0055] The same operation as in Example 1, the difference is that the block catalyst is made of 30%SbF 5 Composed with 70% tungsten oxyfluoride, and the reaction temperature was changed to 100°C, the reaction result was: the conversion rate of 1,1,1,3,3-pentachloropropane was 54.6%, E-1-chloro-3,3, The selectivity of 3-trifluoropropene was 99.1%, and the selectivity of Z-1-chloro-3,3,3-trifluoropropene was 0.9%.

Embodiment 3

[0057] The same operation as in Example 1, the difference is that the block catalyst is made of 25%SbF 5 Composed with 75% tungsten oxyfluoride, and the reaction temperature was changed to 150°C, the reaction result was: the conversion rate of 1,1,1,3,3-pentachloropropane was 71.6%, E-1-chloro-3,3, The selectivity of 3-trifluoropropene was 97.4%, and the selectivity of Z-1-chloro-3,3,3-trifluoropropene was 2.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com