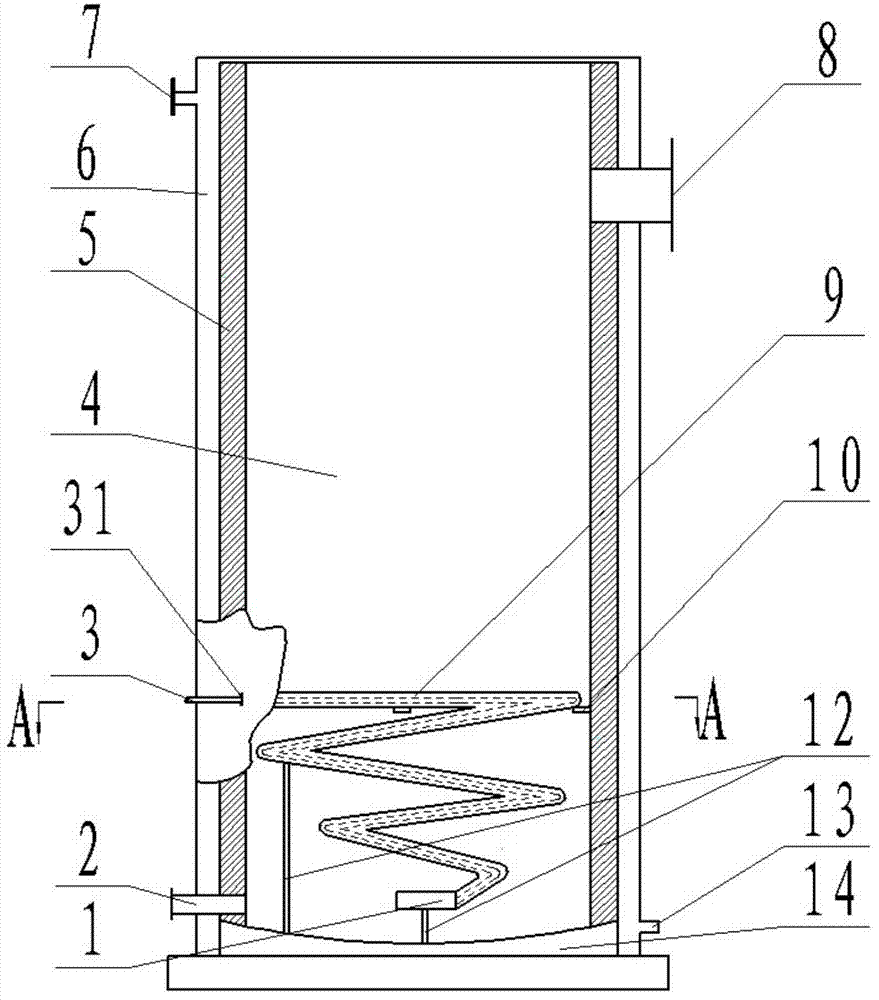

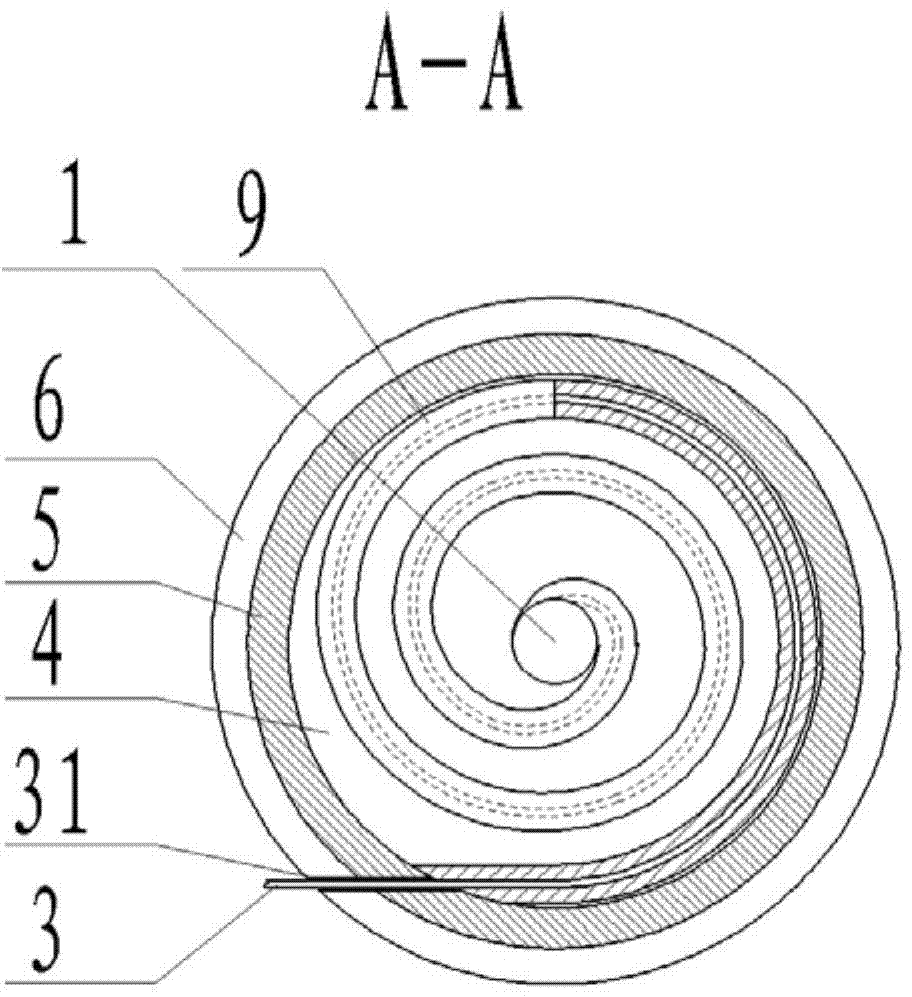

Yellow phosphorus spiral pipe type gasifying combustion furnace

A combustion furnace and yellow phosphorus tube technology, which is applied in the direction of phosphorus oxides, phosphoric acid, phosphorus oxyacids, etc., can solve the problems of increasing investment in equipment funds, increasing energy consumption, and high requirements for transportation safety performance, achieving good economy Benefits and social benefits, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A spiral tube yellow phosphorus gasification combustion furnace includes a combustion furnace 4 connected to a phosphorus melting tank, and the combustion furnace 4 is provided with a spiral gasification tube 3 , a supporting hook 10 and a support frame 11 . The gasification pipe 3 spirals downward around the furnace center in the combustion furnace 4. The tail end of the gasification pipe 3 is placed in the middle of the bottom of the combustion furnace 4. The gasification pipe 3 is fixed on the bracket 10 on the inner wall of the combustion furnace 4. and the supporting frame 11, and the nozzle 1 is arranged at the tail end of the gasification pipe 3, and the nozzle 1 is arranged upward. The other end of the high-temperature graphite layer 9 is connected to the phosphorus melting tank through the sleeve pipe 31 provided by the furnace jacket 6 of the combustion furnace 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com