Preparation method of Na0.3WO3 nanostructure of photothermal conversion material

A light-to-heat conversion material and nanostructure technology, which is applied in the field of preparation of light-to-heat conversion materials, can solve the problems of high requirements for reaction equipment and high production costs, and achieve the effects of high repetition rate, simple operation, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

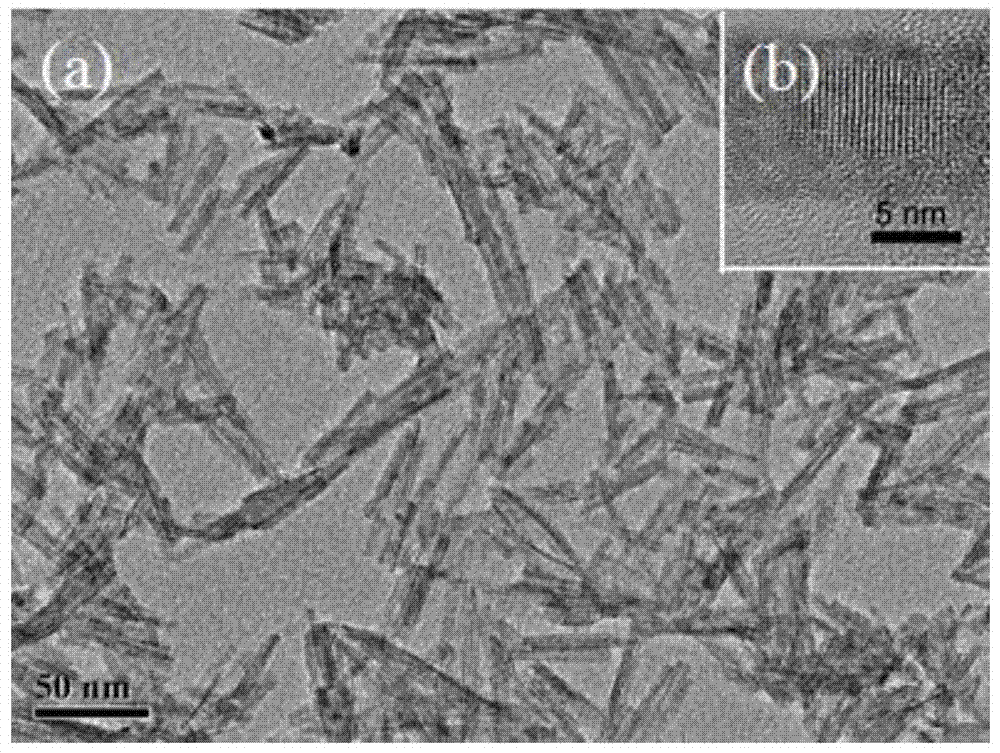

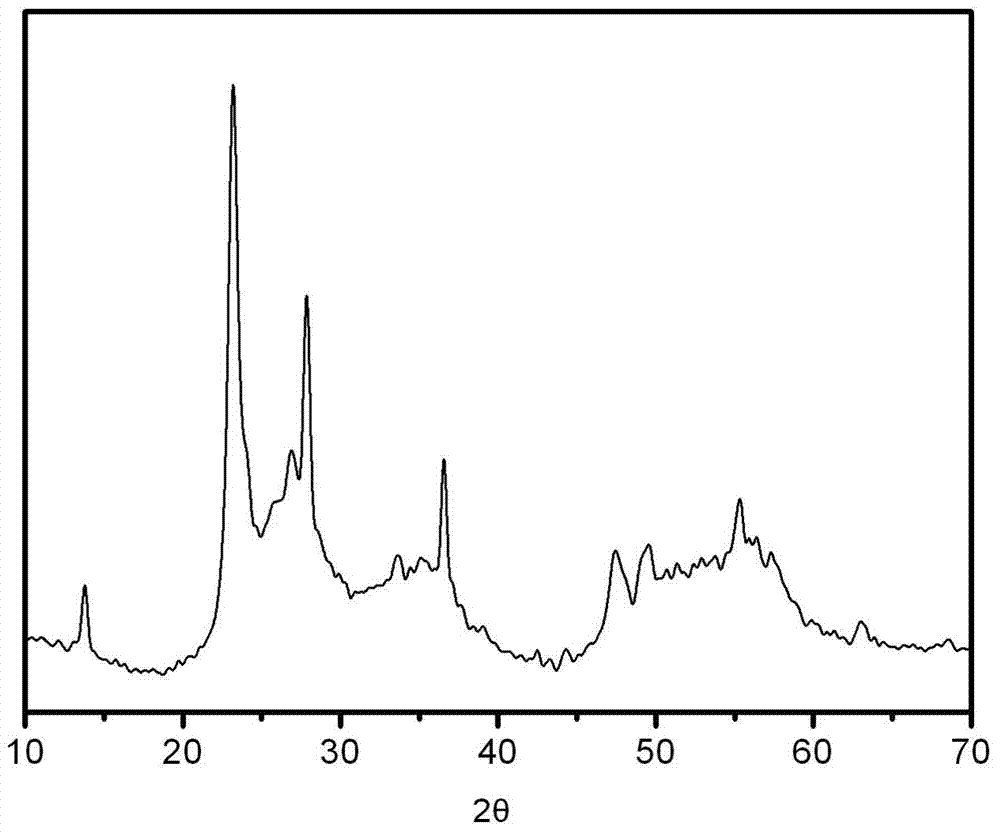

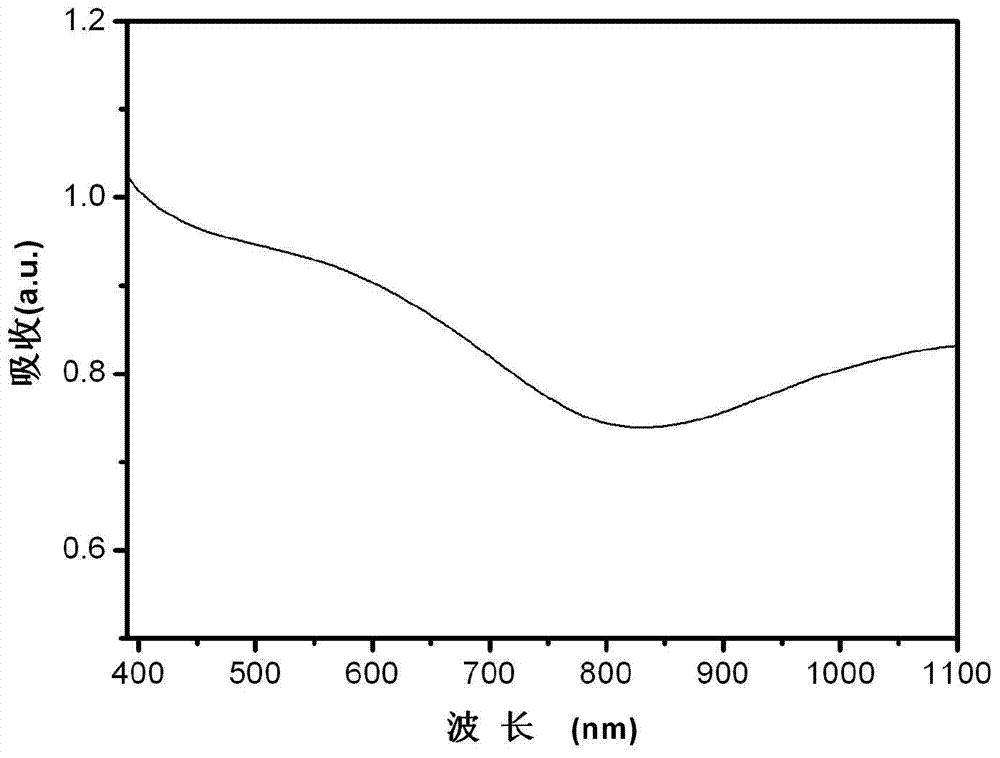

Embodiment 1

[0023] Weigh 0.2380g WCl 6 , 0.0240g NaOH, dissolved in 40mL ethanol, transferred to a 50mL reactor, and reacted at 180°C for 20h. Centrifuge, discard the supernatant, and wash the resulting solid to obtain a blue product, which is Na 0.3 WO 3 Nano-structure. Figure 1-Figure 3 A picture of the product obtained in this example. figure 1 (a) Explain the obtained Na 0.3 WO 3 It is assembled from bundles of nanowires of about 5nm. figure 1 (b) illustrates the growth of the self-assembled structure along the (001) direction (d 001 =0.38nm), and figure 2 Corresponding. image 3 It is the ultraviolet-visible absorption spectrum of the structure, which shows that the self-assembled structure has strong near-infrared absorption and is expected to be used in photothermal therapy.

Embodiment 2

[0025] Weigh 0.2380g WCl 6 , 0.0120g NaOH, dissolved in 40mL ethanol, transferred to a reaction kettle with a capacity of 50mL, and reacted at 180°C for 20h. Centrifuge, discard the supernatant, and wash the resulting solid to obtain a blue product, which is Na 0.3 WO 3 Nano-structure.

Embodiment 3

[0027] Weigh 0.2380g WCl 6 , 0.0120g NaOH, dissolved in 40mL ethanol, transferred to a reaction kettle with a capacity of 50mL, and reacted at 180°C for 24h. Centrifuge, discard the supernatant, and wash the resulting solid to obtain a blue product, which is Na 0.3 WO 3 Nano-structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com