1-ethyl-4-alkylpiperazine ionic liquid and preparation method and application thereof

A technology of alkylpiperazine and ionic liquid, which is applied in the field of 1-ethyl-4-alkylpiperazine ionic liquid, can solve the problems of poor stability, few types, short preparation cycle, etc., and achieve easy functionalization and short cycle , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

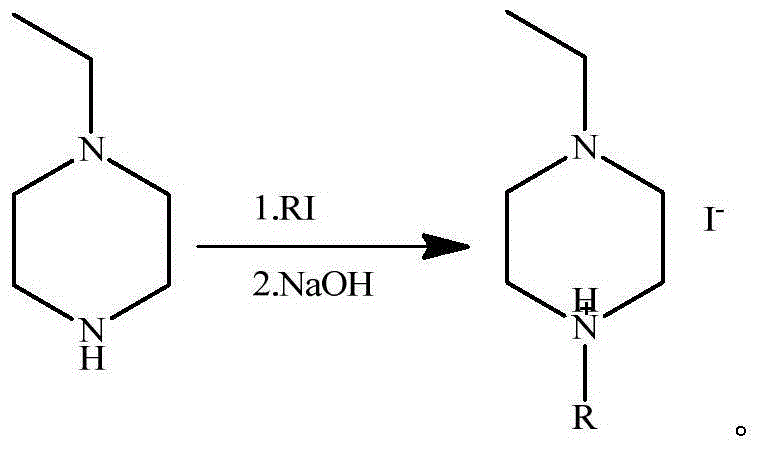

[0036] Embodiment 1: Preparation of iodide 1-ethyl-4-propylpiperazine ionic liquid

[0037] Dissolve 0.11 mol of iodopropane in 50 mL of dichloromethane, drop slowly into 0.1 mol of 1-ethylpiperazine, and react with stirring at 20°C for 20 hours. After the reaction was completed, 0.12 mol of sodium hydroxide was added to the reaction solution, and the reaction was continued at 20° C. for 24 hours. After the reaction, filter to remove solid impurities, evaporate dichloromethane, and wash the crude product twice with n-hexane, evaporate n-hexane, and dry under vacuum at 40°C to obtain 1-ethyl-4-propylpiperazine iodide ion Liquid, 98% purity, 90% yield.

[0038] The reaction formula is:

[0039]

Embodiment 2

[0040] Embodiment 2: Preparation of iodide 1-ethyl-4-butylpiperazine ionic liquid

[0041]Dissolve 0.1 mol of iodobutane in 50 mL of dichloromethane, drop slowly into 0.1 mol of 1-ethylpiperazine, and react with stirring at 5°C for 24 hours. After the reaction was completed, 0.14 mol of sodium hydroxide was added to the reaction liquid, and the reaction was continued at 25° C. for 24 hours. After the reaction, filter to remove solid impurities, evaporate dichloromethane, wash the crude product twice with n-hexane, evaporate n-hexane, and dry under vacuum at 40°C to obtain 1-ethyl-4-butylpiperazine iodide Liquid, 99% purity, 86% yield.

[0042] The reaction formula is:

[0043]

Embodiment 3

[0044] Embodiment 3: Preparation of iodide 1-ethyl-4-hexylpiperazine ionic liquid

[0045] Dissolve 0.09 mol of iodohexane in 50 mL of dichloromethane, drop slowly into 0.1 mol of 1-ethylpiperazine, and react with stirring at 40°C for 24 hours. After the reaction was completed, 0.12 mol of sodium hydroxide was added to the reaction liquid, and the reaction was continued at 40° C. for 24 hours. After the reaction, remove solid impurities by filtration, evaporate dichloromethane, wash the crude product twice with n-hexane, evaporate n-hexane, and dry under vacuum at 40°C to obtain 1-ethyl-4-hexylpiperazine iodide ionic liquid , 98% purity, 88% yield.

[0046] The reaction formula is:

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com