Preparation method for high isotactic polybutene-1

A high-tactic polybutene and pre-polymerization technology, applied in the field of olefin polymerization, can solve the problem of unspecified particle shape characteristics of products in the polymerization process, and achieve the effects of low cost, high efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The main catalyst (titanium-containing solid catalyst active component) is obtained by the method described in Example 1 of Chinese Patent CN93102795, its Ti content: 2.2wt%, diisobutyl phthalate content: 11.2wt%.

[0040] Add 50ml of hexane into a 500ml pressure-resistant glass reactor, lower the temperature of the system to 0°C, and then add the main catalyst, cocatalyst (triethylaluminum) and part of the external electron donor that have been pre-complexed at room temperature for 2 minutes (tetraethoxysilane), then add 0.5 bar of hydrogen, and then add 20ml of butene to start the pre-polymerization reaction. After 4 minutes, more fine sand-like polymers appear, and filter out the system with a filter head with a filter pore size of 5um. Most of the hexane, 300ml of butene was added to the system, the temperature was raised to 30°C to enter the bulk polymerization stage, and the polymerization was continued for 2 hours.

[0041] After the reaction is finished, the sys...

Embodiment 2

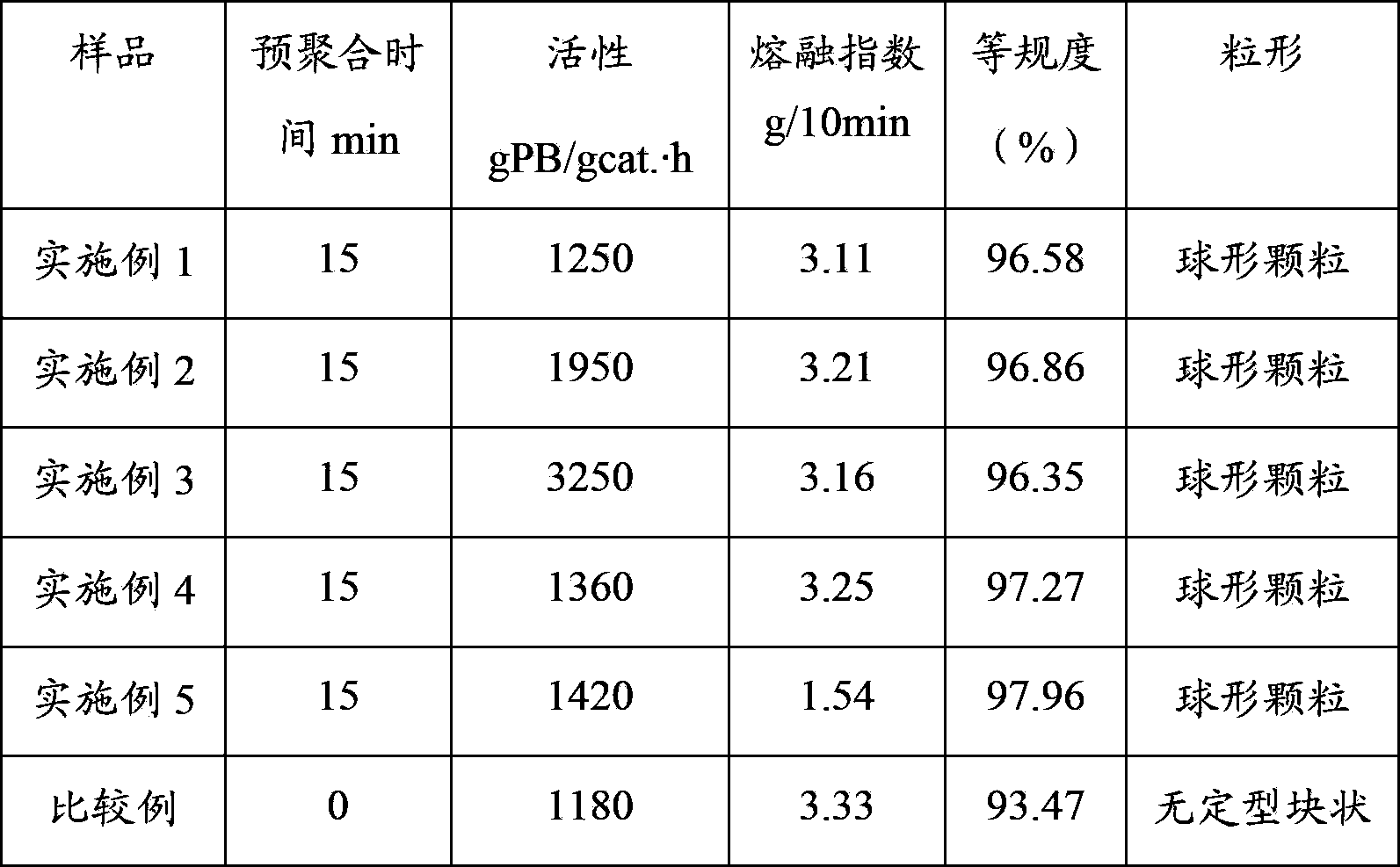

[0043] The cocatalyst, aluminum alkyl, precomplexation and polymerization process conditions used in embodiment 2 are the same as in embodiment 1. The difference from Example 1 is that the main catalyst used in Example 2 is the catalyst described in Example 8 of Chinese Patent CN200410073623.8. The specific process conditions are shown in Table 1.

Embodiment 3

[0045] The cocatalyst, aluminum alkyl, precomplexation and polymerization process conditions used in embodiment 3 are the same as in embodiment 1. The difference from Example 1 is that the main catalyst used in Example 3 is the catalyst described in Example 1 of Chinese Patent No. 200910163055.X. The specific process and product performance characterization are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com