Anti-dazzle film and manufacturing method therefor

An anti-glare film and anti-glare layer technology, applied in coatings, instruments, electrical components, etc., can solve the problems of reducing glare, easy to produce glare, difficult anti-glare, etc., and achieve both anti-glare and glare resistance, Excellent haze and sharpness, and the effect of suppressing blurring of characters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

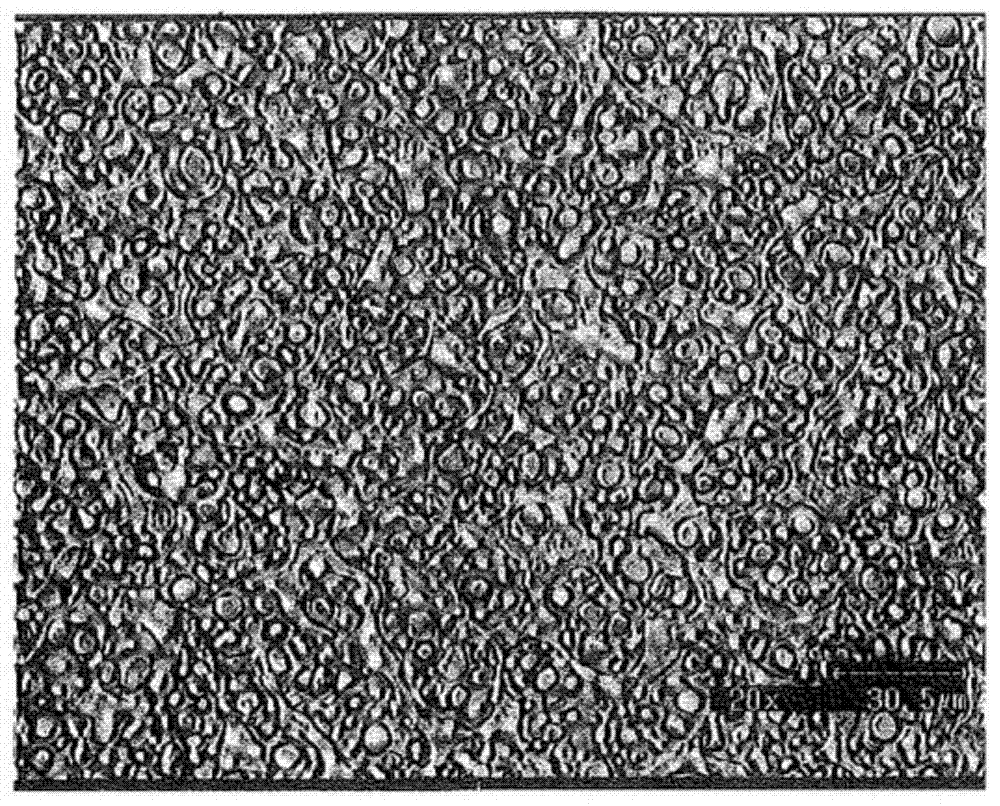

[0184] An acrylic resin having a polymerizable unsaturated group in the side chain [made by adding 3,4-epoxycyclohexenyl methacrylate to a part of the carboxyl group of (meth)acrylic acid-(meth)acrylate copolymer The compound; "CYCLOMER P (ACA) 320M" manufactured by Daicel Co., Ltd., solid content: 49.6% by weight] 5.65 parts by weight, cellulose acetate propionate (degree of acetylation = 2.5%, degree of propionylation = 46%, poly Styrene-equivalent number average molecular weight: 75,000; "CAP-482-20" manufactured by Eastman Co., Ltd.) 1.2 parts by weight, polyfunctional acrylic UV-curable compound ("DPHA" manufactured by Daicel-Cytec Co., Ltd., viscosity: 5250 mPa·s) 4 Parts by weight, 2.77 parts by weight of an acrylic UV curable compound ("PET1A" manufactured by Daicel-Cytec, viscosity 1100mPa·s), and 0.53 parts by weight of a photoinitiator ("IRGACURE907" manufactured by BASF Corporation) were dissolved in methyl ethyl ketone (MEK ) in a mixed solvent of 25 parts by weig...

Embodiment 2

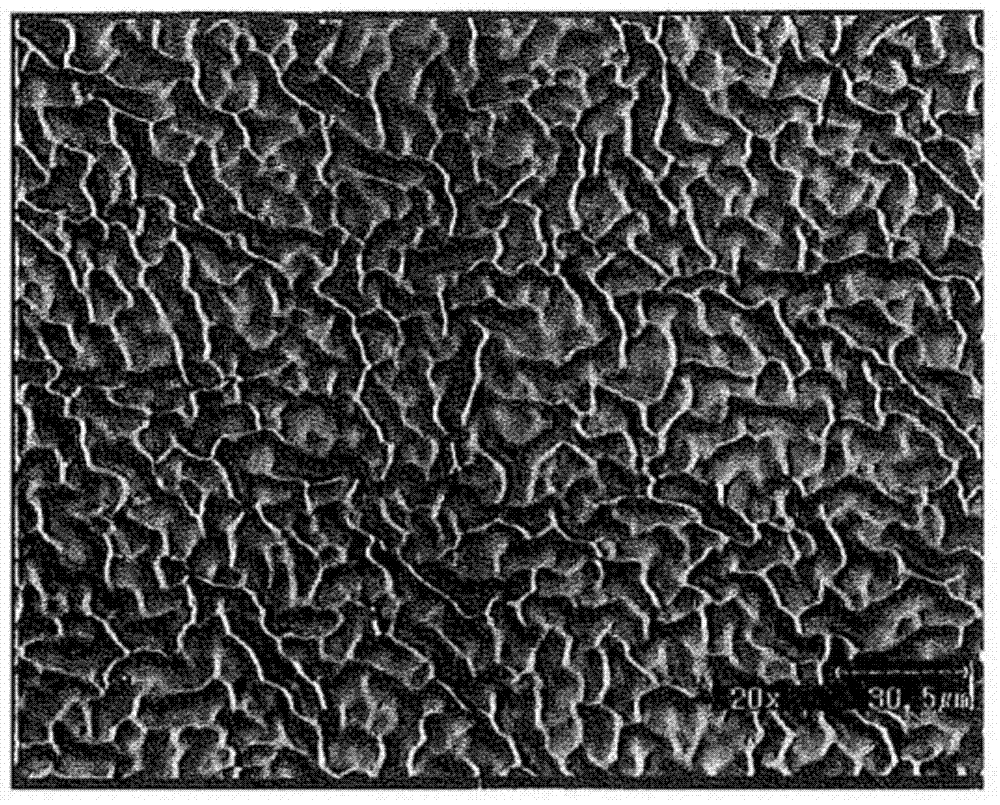

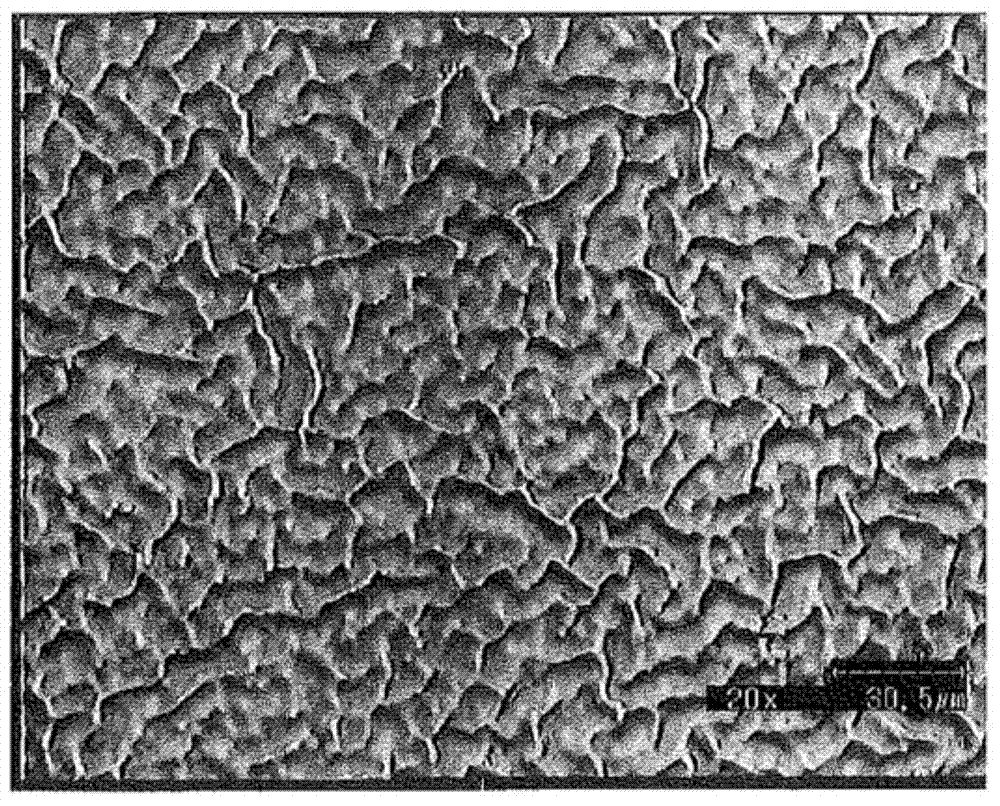

[0188] Acrylic resin [CYCLOMER P (ACA) 320M] 5.65 parts by weight, 1.2 parts by weight of cellulose acetate propionate (CAP-482-20), multifunctional acrylic UV curable compound ( DPHA) 6 parts by weight, 0.77 parts by weight of acrylic UV-curable compound containing silicone ("EB1360" manufactured by Daicel-Cytec Co., Ltd., viscosity: 2100 mPa·s), and 0.53 parts by weight of photoinitiator (IRGACUR907) were dissolved In a mixed solvent of 25 parts by weight of MEK and 12.15 parts by weight of 1-butanol. After casting this solution on a PET film (A4300) with a thickness of 100 μm using a wire-wound paint bar #24, it was placed in an oven at 90°C for 2 minutes to evaporate the solvent and form a coating with a thickness of about 7 μm . Then, the coating was irradiated with ultraviolet light from a high-pressure mercury lamp (manufactured by Eyegraphics) for about 10 seconds to perform UV curing.

[0189] Observation by reflection laser microscope, the results are as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com