Oil-in-water submicron emulsion serving as vaccine adjuvant and preparation method thereof

An oil-in-water vaccine adjuvant technology, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, can solve the problems of antigen titer reduction and inactivation, and achieve stability sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

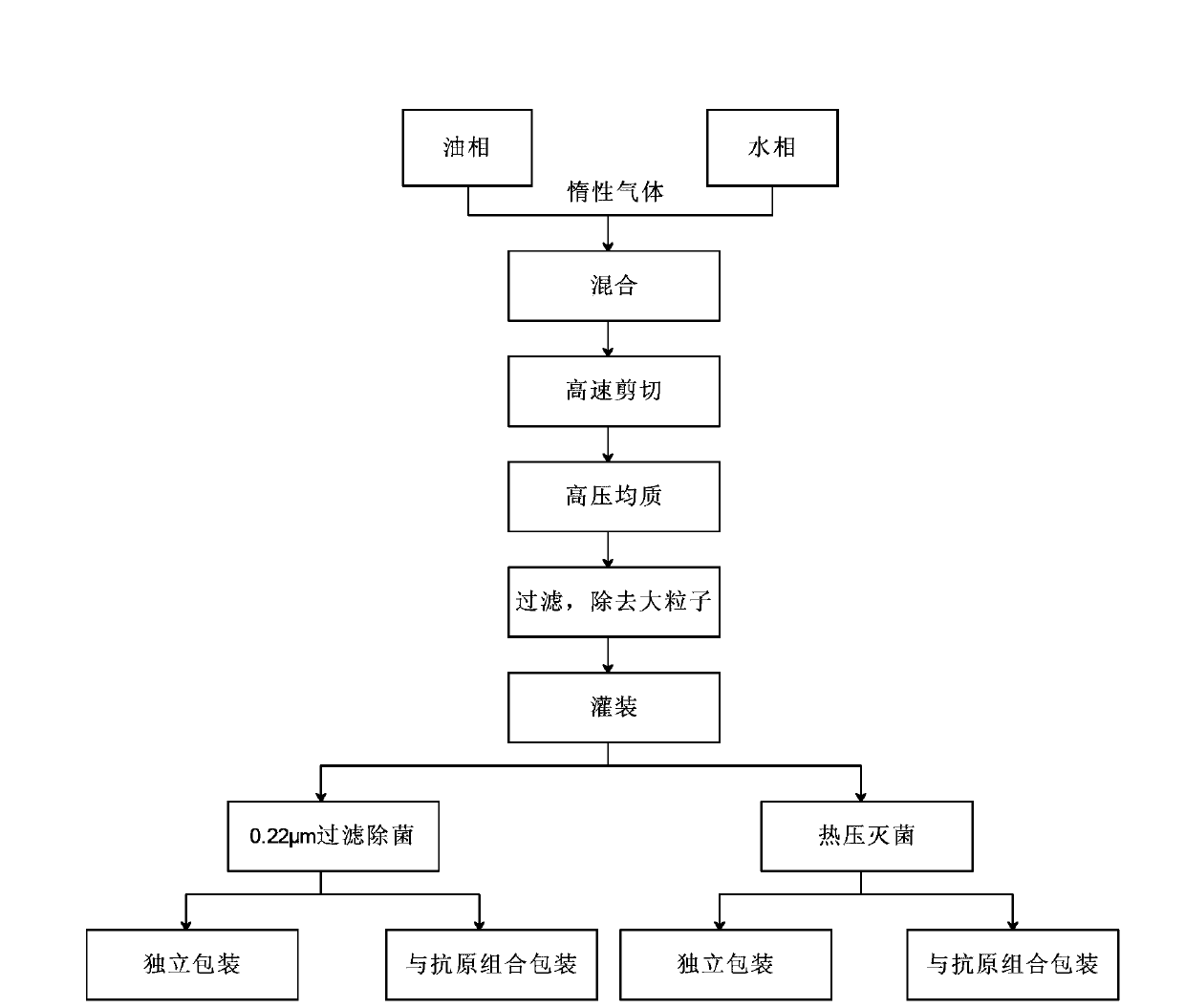

[0050] Embodiment 1: the preparation of oil-in-water type submicroemulsion

[0051] Under an inert gas environment, 50 g of squalene and 6.0 g of egg yolk lecithin (containing 80% phosphatidylcholine) were weighed, stirred and mixed evenly, as the oil phase.

[0052] Weigh 0.3 g of sodium oleate and 25 g of glycerin, add an appropriate amount of water for injection, stir and mix evenly, and use it as the water phase.

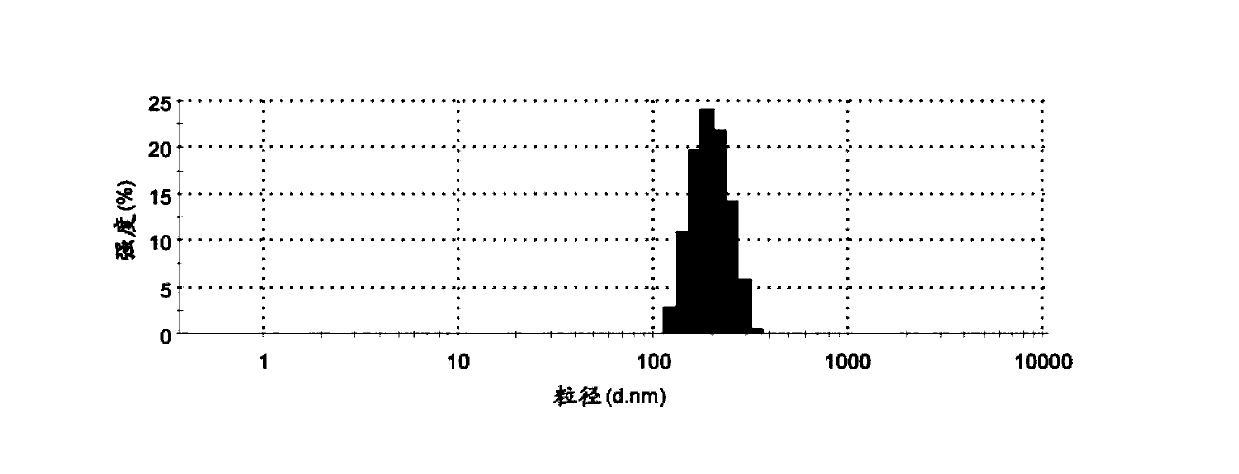

[0053] In an inert gas environment, the oil phase and the water phase are mixed, and the high-speed shear is continued to form colostrum. Add about 0.1ml of 1mol / L NaOH to adjust the pH value of colostrum to 5.0-10.0, and dilute to 1000ml with water for injection. Transfer to a high-pressure homogenizer for homogenization until the emulsion droplet size is reduced to a qualified level, after filtering, filling, autoclaving, and cooling to obtain the submicroemulsion vaccine adjuvant.

Embodiment 2

[0054] Embodiment 2: the preparation of oil-in-water type submicroemulsion

[0055] Under an inert gas environment, 50 g of squalene and 6.0 g of egg yolk lecithin (containing 80% phosphatidylcholine) were weighed, stirred and mixed evenly, as the oil phase.

[0056] Weigh 25g of glycerin, add an appropriate amount of water for injection, stir and mix evenly, and use it as the water phase.

[0057] In an inert gas environment, the oil phase and the water phase are mixed, and the high-speed shear is continued to form colostrum. Add about 0.1ml of 1mol / L NaOH to adjust the pH value of colostrum to 5.0-10.0, and dilute to 1000ml with water for injection. Transfer to a high-pressure homogenizer for homogenization until the emulsion droplet size is reduced to a qualified level, after filtering, filling, autoclaving, and cooling to obtain the submicroemulsion vaccine adjuvant.

Embodiment 3

[0058] Embodiment 3: the preparation of oil-in-water type submicroemulsion

[0059] Under an inert gas environment, 10 g of squalene and 0.5 g of egg yolk lecithin (containing 80% phosphatidylcholine) were weighed, stirred and mixed evenly, and used as the oil phase.

[0060] Weigh 20 g of glycerin, add an appropriate amount of water for injection, stir and mix evenly, and use it as the water phase.

[0061] In an inert gas environment, the oil phase and the water phase are mixed, and the high-speed shear is continued to form colostrum. Add an appropriate amount of 1mol / L KOH to adjust the pH value of the colostrum to 5.0-10.0, and dilute to 1000ml with water for injection. Transfer to a high-pressure homogenizer for homogenization until the emulsion droplet size is reduced to a qualified level, after filtering, filling, autoclaving, and cooling to obtain the submicroemulsion vaccine adjuvant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com