Modification method for titanium silicalite molecular sieves

A titanium-silicon molecular sieve, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of decreased catalytic activity, influence of strip catalyst strength, diffusion to the outside, etc., to improve catalytic activity. , excellent catalytic activity, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

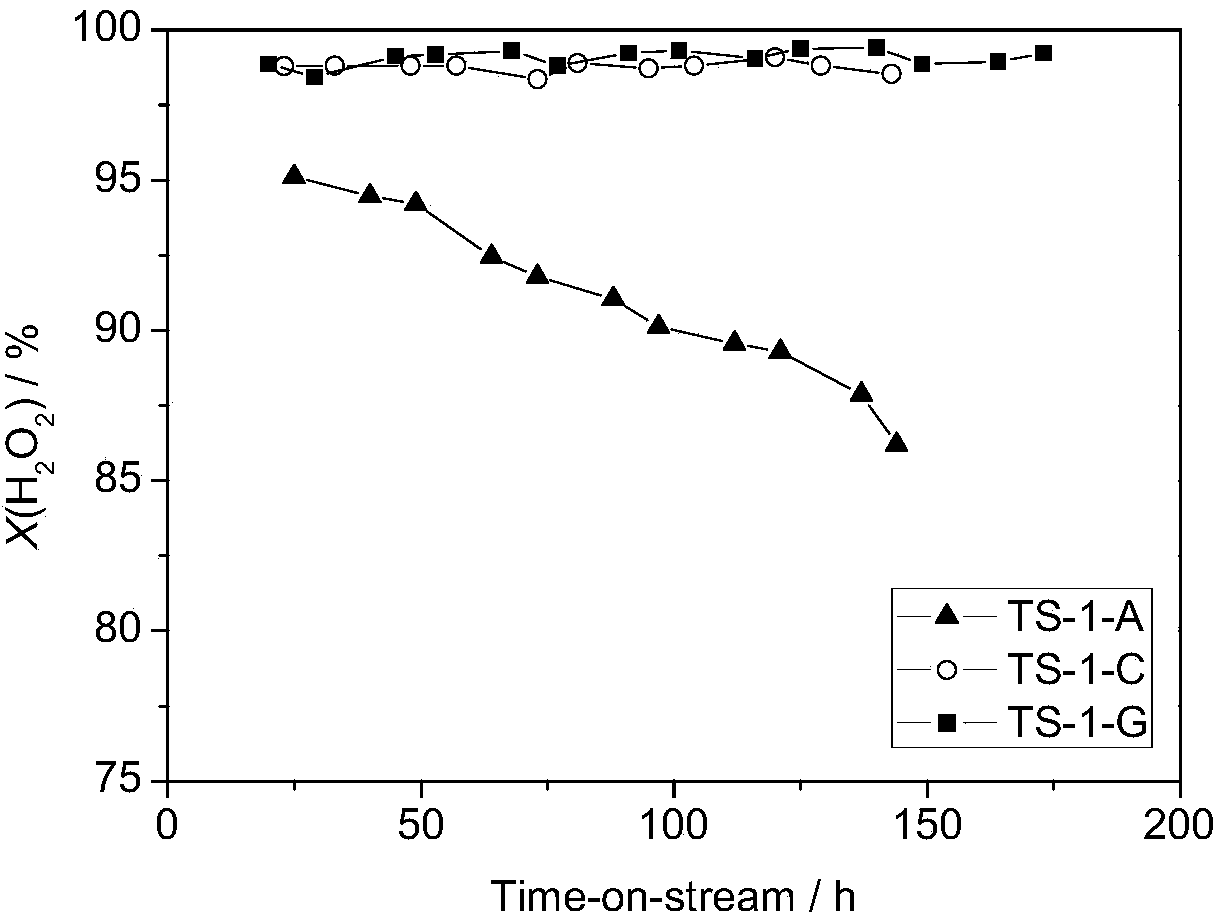

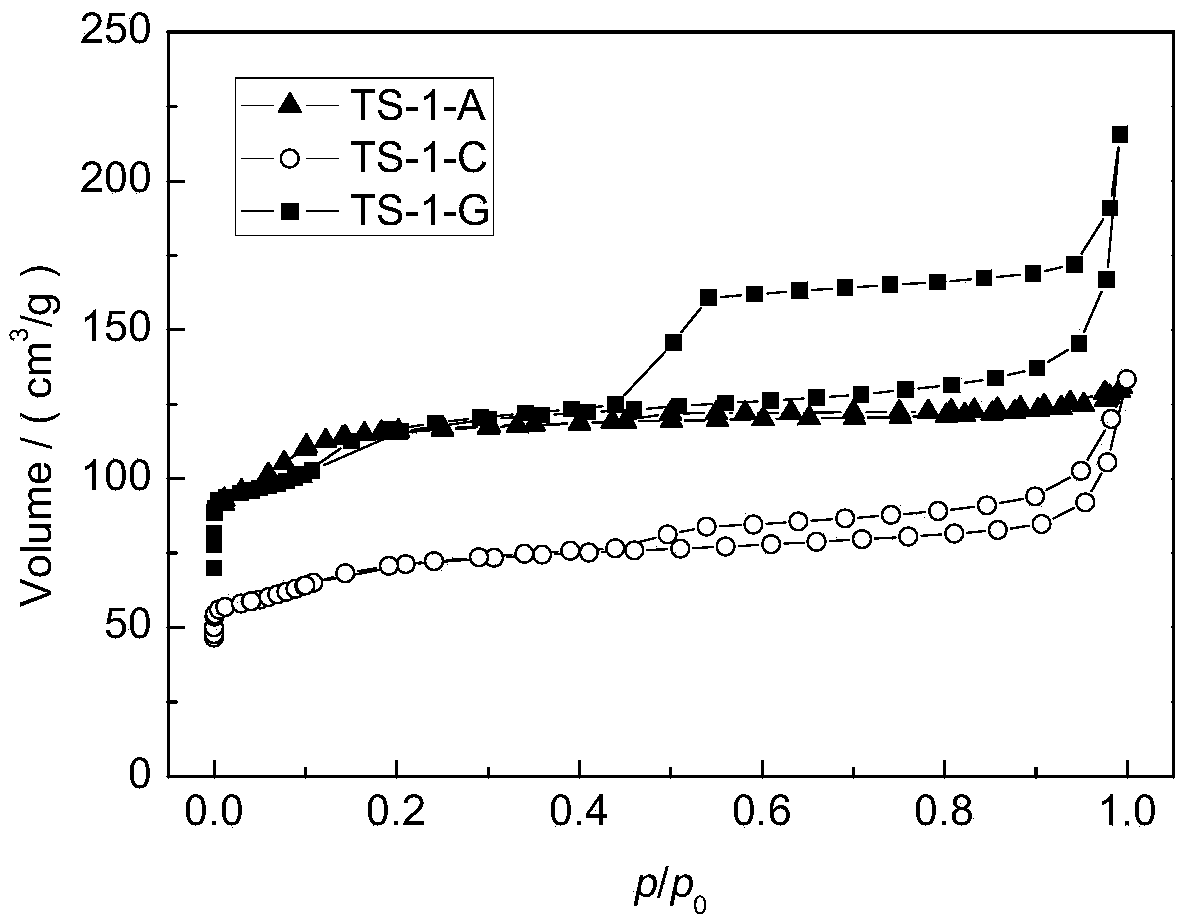

Embodiment 1

[0036] Mix 8g of strip-shaped TS-1-A sample with 80mL of 0.06mol / L ethylamine aqueous solution, put it into a 100mL stainless steel crystallization kettle with polytetrafluoroethylene lining, and modify it at 170℃ under autogenous pressure After 48 hours, it was taken out and subjected to solid-liquid separation, and the solid was washed with deionized water until neutral, then dried and roasted at 540°C for 6 hours, and the obtained TS-1 sample was numbered TS-1-C.

Embodiment 2

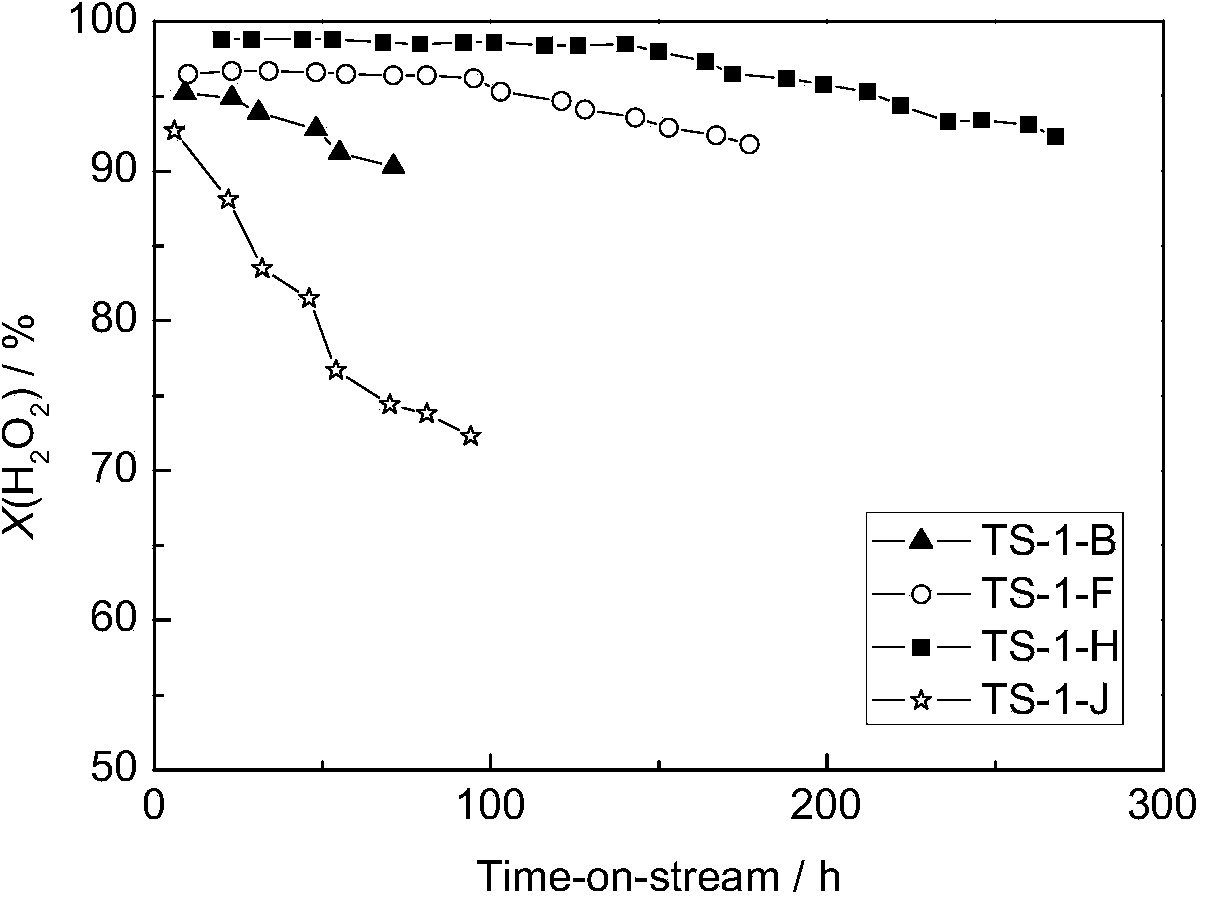

[0038] The strip-shaped TS-1-B sample was treated in the same manner as in Example 1, and the obtained TS-1 sample was numbered TS-1-D.

Embodiment 3

[0040] The strip TS-1-A sample is treated in the same way as in Example 1, except that the modifier is replaced by a 0.04mol / L tetrapropylammonium hydroxide aqueous solution, and the obtained TS-1 sample is numbered for TS-1-E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com