Integrated device for heavy metal contaminated soil remediation and leacheate recycling and method thereof

A technology for polluted soil and heavy metals, applied in the restoration of polluted soil and other directions, can solve the problems of unreusable washing liquid, low efficiency of cyclic leaching, secondary pollution, etc. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 An integrated device for remediation of heavy metal-contaminated soil and recycling of eluent

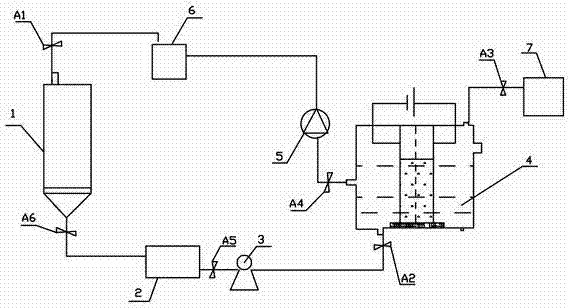

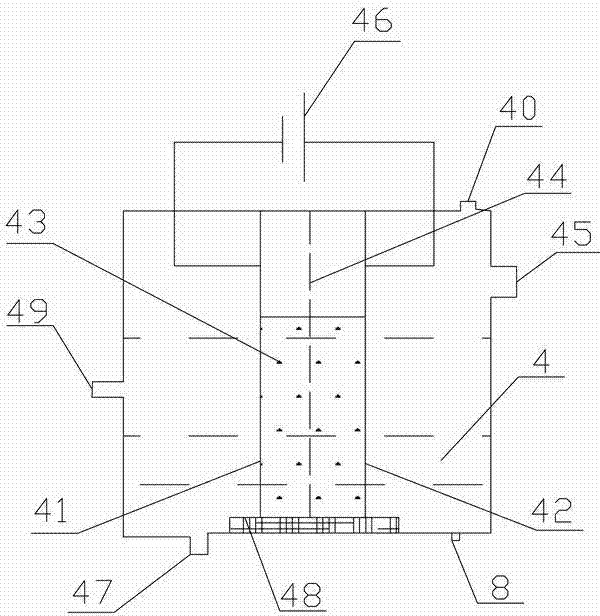

[0040] Such as figure 1 As shown, this embodiment is an integrated device for remediation of heavy metal-contaminated soil and eluent recycling, which includes a leaching tower 1, a sedimentation tank 2, a water pump 3, and an electrochemical reactor 4 that are sequentially connected in a ring through communication pipes. , a circulation pump 5, a first liquid storage tank 6, and a second liquid storage tank 7 is arranged outside the electrochemical reactor 4.

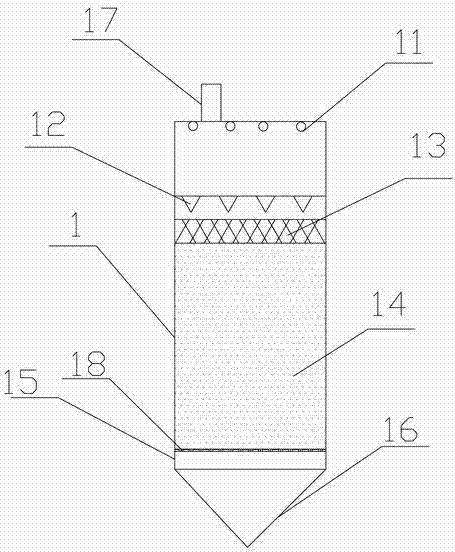

[0041] Such as figure 2 As shown, the washing tower 1 includes a first liquid inlet 17 , a nozzle 11 , a baffle 15 , a first gauze layer 13 , a second gauze layer 18 , a pebble layer 12 , heavy metal contaminated soil 14 , and a funnel 16 . The top of the leaching tower 1 is provided with a first liquid inlet 17 connected to the first liquid storage tank 6 through a connecting pipe, and a plurality of s...

Embodiment 2

[0050] Example 2 A method for remediation of heavy metal-contaminated soil and recycling of eluent

[0051] This embodiment is a method for remediation of heavy metal-contaminated soil and recycling of eluent, which is realized by relying on the integrated device described in Embodiment 1, and is carried out according to the following sequence of steps:

[0052] ①In the leaching tower, the heavy metal contaminated soil is leached by EDTA solution with a pH of 3 and a concentration of 0.01mol / L. The liquid-solid ratio in the leaching tower is 20, and liquid A is obtained at the bottom of the tower;

[0053] ② After liquid A was settled in the sedimentation tank for 10 minutes, the upper layer obtained liquid B;

[0054] ③Liquid B is pumped into the electrochemical reactor filled with 0.01mol / L sodium sulfate solution, and the valve of the second liquid storage tank is opened to flow into Fe 2+ with H 2 o 2 The molar ratio of Fenton's reagent is 1:2, the flow rate of Fenton...

Embodiment 3-6

[0058] Embodiment 3-6 Method for remediation of heavy metal contaminated soil and recycling of eluent

[0059] Embodiments 3-6 are respectively a method for remediation of heavy metal-contaminated soil and recycling of eluent, and the device used is the same as in Example 1. In each embodiment, the method for remediation of heavy metal-contaminated soil and recycling of eluent, heavy metal pollution The soil is similar to that of Example 2, except that the difference is shown in Table 1, which is that the relevant control parameters in the restoration process are different.

[0060] Table 1 The corresponding control parameters in the method of heavy metal contaminated soil remediation and eluent recycling

[0061]

[0062] As can be seen from the above table, after the treatment of heavy metal-contaminated soil in Examples 3-6, the removal rate of heavy metals is high, the efficiency of repair is high, and the number of leaching times is small. Secondary pollution, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com