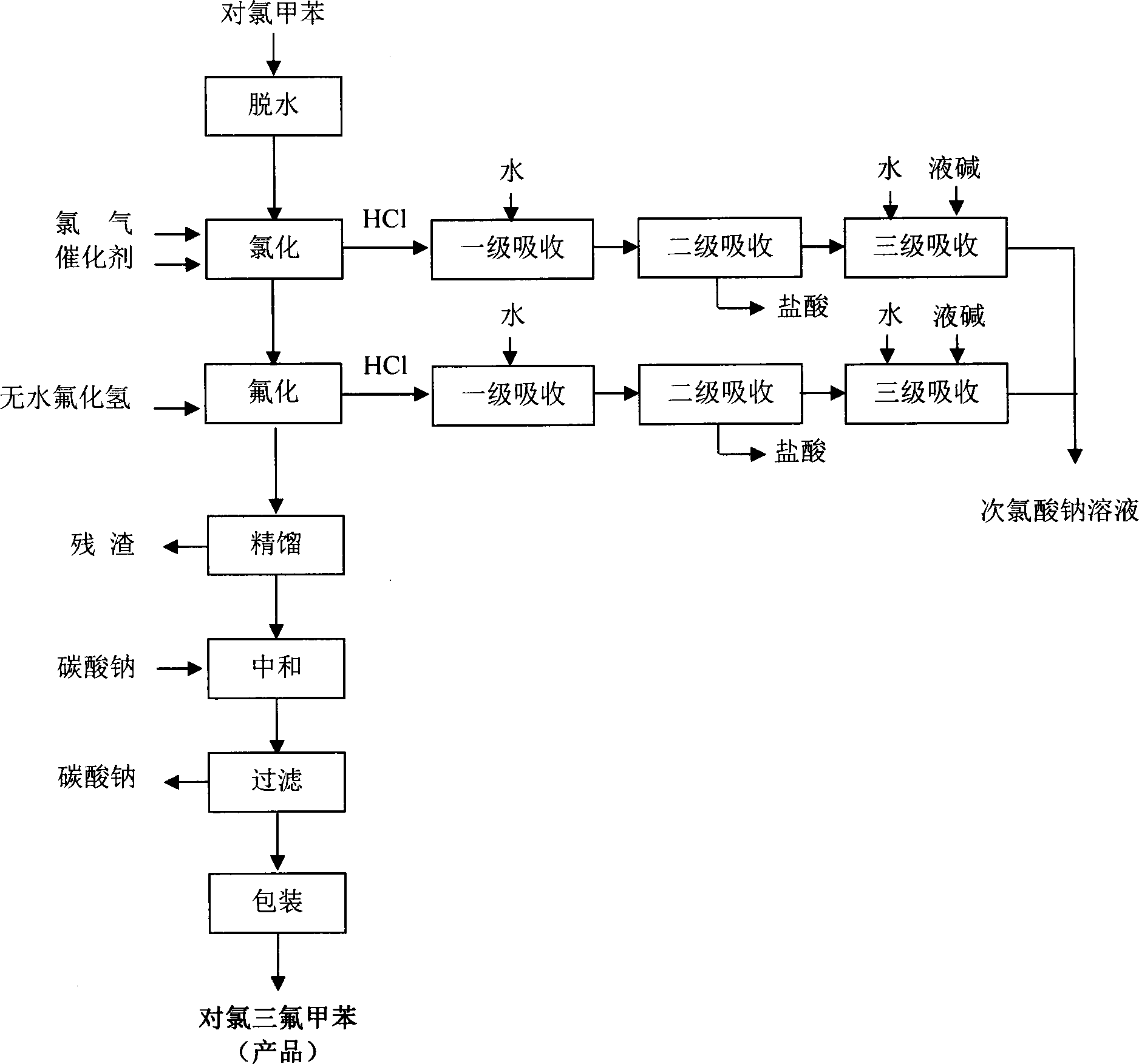

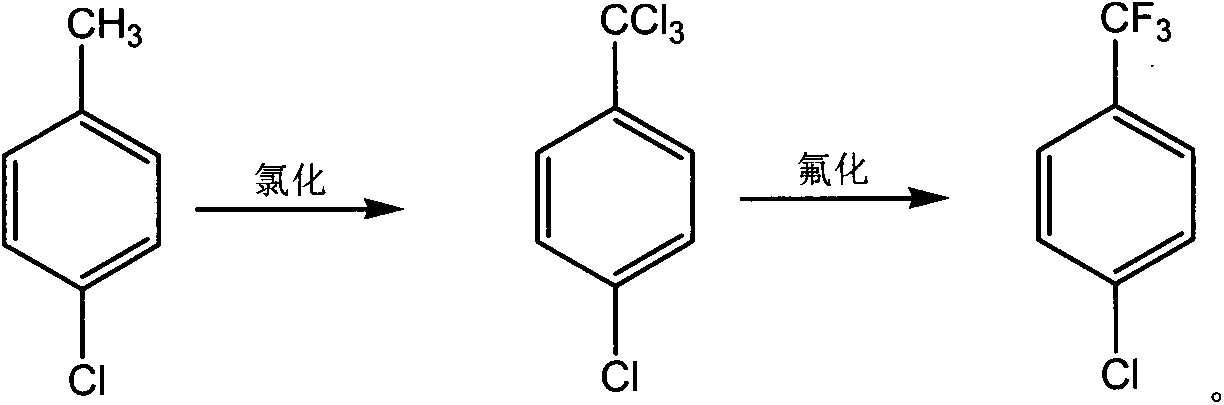

P-chlorobenzotrifluoride synthesizing method

A technology of p-chlorobenzotrifluoride and p-chlorobenzotrichloride, which is applied in the field of preparation of pesticide chemical intermediate products, can solve the problems of low absorption and utilization rate of chlorine gas, low reaction yield, etc., and achieve remarkable economic and social benefits , easy operation, reduction of by-products and exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Chlorination: 630g p-chlorotoluene is put into dehydration kettle, after being heated to 80 ℃ to remove moisture content, obtain 629g p-chlorobenzotrifluoride, put into 3L chlorination reaction kettle, heat up to 110 ℃, add 40g catalyst (minutes) Add 4 batches, each batch 10g), start to feed dry chlorine gas, the flow rate is 40-80m 3 / h, then add the catalyst every 30 minutes, control the temperature at 110-112°C, and the reaction time is 24 hours. After sampling and analyzing the chlorinated material as qualified, stop the chlorine flow. The p-chlorotrichlorotoluene produced by chlorination is pumped into the chlorination tank for use, and the tail gas generated by the reaction is sent to the tail gas absorption device.

[0030] (2) Fluorination: Press 4 moles of p-chlorotrichlorotoluene and 12 moles of anhydrous hydrogen fluoride into a 3L fluorination reaction kettle, open the frozen brine system, press hydrogen fluoride into the fluorination kettle with 0.2MPa...

Embodiment 2

[0034] (1) Chlorination: 630g p-chlorotoluene is put into dehydration kettle, after being heated to 80 ℃ to remove moisture content, obtain 629g p-chlorobenzotrifluoride, put into 3L chlorination reactor, heat up to 110 ℃, add 80g catalyst (minutes) Add in 4 batches, each batch is 20g), and start to feed dry chlorine gas with a flow rate of 40-80m 3 / h, then add the catalyst every 30 minutes, control the temperature at 110-112°C, and the reaction time is 20 hours. After sampling and analyzing the chlorinated material as qualified, stop the chlorine flow. The p-chlorotrichlorotoluene produced by chlorination is pumped into the chlorination tank for use, and the tail gas generated by the reaction is sent to the tail gas absorption device.

[0035] (2) Fluorination: Press 4 moles of p-chlorotrichlorotoluene and 14 moles of anhydrous hydrogen fluoride into a 3L fluorination reaction kettle, open the frozen brine system, press hydrogen fluoride into the fluorination kettle with 0....

Embodiment 3

[0039] (1) Chlorination: 630g p-chlorotoluene is put into dehydration kettle, is heated to 80 ℃ to remove moisture content and obtains 629g p-chlorobenzotrifluoride, puts into 3L chlorination reaction kettle, heats up to 110 ℃, adds 60g catalyst (minutes) Add in 4 batches, each batch is 15g), and start to feed dry chlorine gas with a flow rate of 40-80m 3 / h, then add the catalyst every 30 minutes, control the temperature at 110-112°C, and the reaction time is 22 hours. After sampling and analyzing the chlorinated material as qualified, stop the chlorine flow. The p-chlorotrichlorotoluene produced by chlorination is pumped into the chlorination tank for use, and the tail gas generated by the reaction is sent to the tail gas absorption device.

[0040] (2) Fluorination: Press 4 moles of p-chlorotrichlorotoluene and 13 moles of anhydrous hydrogen fluoride into a 3L fluorination reaction kettle, open the frozen brine system, press hydrogen fluoride into the fluorination kettle w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com