Acrylamide monomer and its method of preparation, acrylamide copolymer and method of preparation, and application

An acrylamide copolymer and acrylamide copolymerization technology are applied in the preparation of sulfonic acid, compositions for drilling, chemical instruments and methods, etc., can solve problems such as poor temperature resistance and salt resistance, and achieve less curling and improved salt resistance. performance, the effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This example is used to illustrate the acrylamide monomer and acrylamide copolymer provided by the present invention and its preparation method

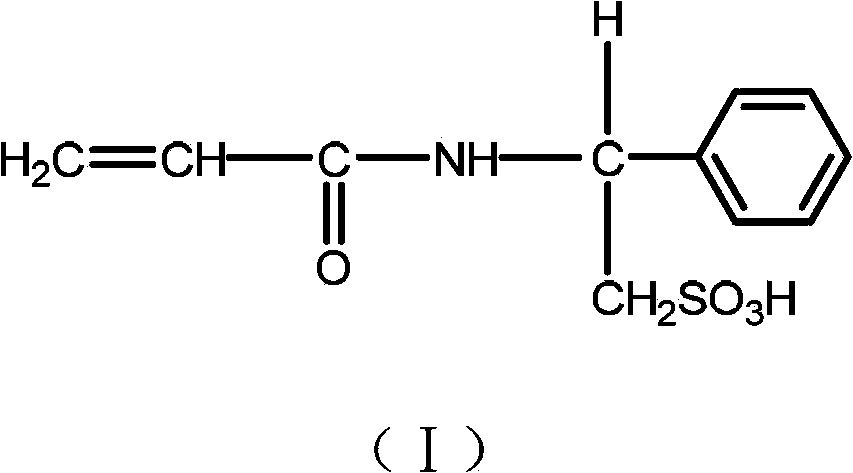

[0094] (1) Preparation of acrylamide monomer

[0095] Add 100 kg of concentrated sulfuric acid with a weight concentration of 98% into the reaction kettle, add 530 kg of acrylonitrile, cool the mixture to -5°C, stir evenly, add 104.14 kg of styrene, and keep the temperature of the reaction system below 5°C. Continue to stir the reaction for 2h, static, and crystals are precipitated. After filtering, washing, refining and drying, the pure monomer was obtained, and the product yield was 95.5%, and the acrylamide monomer M1 was obtained.

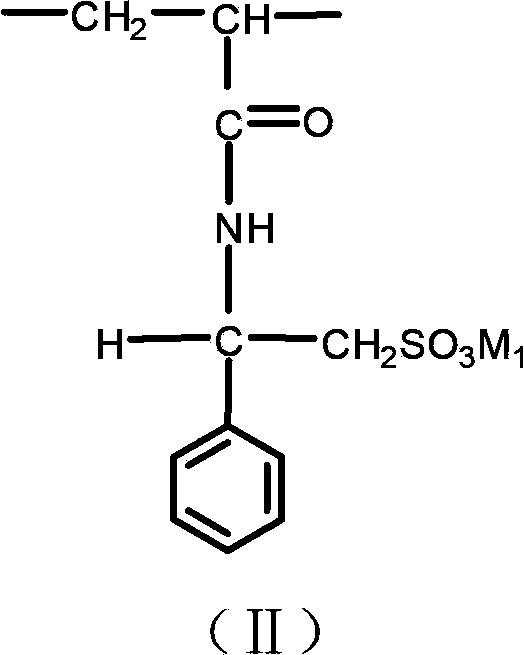

[0096] (2) Preparation of acrylamide copolymer

[0097] Add 927.09 kg of acrylamide (AM) and 831.46 kg of acrylamide monomer M1, and 7034.2 kg of deionized water into the batching kettle. While stirring, use frozen brine to control the solution temperature -7°C, and add sodium hydroxide to ad...

Embodiment 2

[0101] This example is used to illustrate the acrylamide monomer and acrylamide copolymer provided by the present invention and the preparation method thereof.

[0102] (1) Preparation of acrylamide monomer

[0103] Add 117.6 kg of concentrated sulfuric acid with a weight concentration of 98% to the reaction kettle, add 1060 kg of acrylonitrile, cool the mixture to 15°C, stir evenly, add 104.14 kg of styrene, and keep the temperature of the reaction system below 5°C. Continue to stir the reaction for 4h, static, and crystals are precipitated. After filtering, washing, refining and drying, the pure monomer was obtained, and the product yield was 96%, and the acrylamide monomer M2 was obtained.

[0104] (2) Preparation of acrylamide copolymer

[0105] Add 1108.85 kg of AM, 102.00 kg of acrylamide monomer M2, and 2825.3 kg of deionized water into the batching kettle. While stirring, control the temperature of the solution with frozen brine to 15°C, and add sodium hydroxide to a...

Embodiment 3

[0107] This example is used to illustrate the acrylamide monomer and acrylamide copolymer provided by the present invention and the preparation method thereof.

[0108] (1) Preparation of acrylamide monomer

[0109] Add 107.8 kg of concentrated sulfuric acid with a weight concentration of 98% to the reaction kettle, add 636 kg of acrylonitrile, cool the mixture to 5°C, stir evenly, add 104.14 kg of styrene, and keep the temperature of the reaction system below 5°C. Continue to stir the reaction for 3h, static, and crystals are precipitated. After filtering, washing, refining and drying, the pure monomer was obtained, and the product yield was 97%, and the acrylamide monomer M3 was obtained.

[0110] (2) Preparation of acrylamide copolymer

[0111] Add 1,080.4 kg of AM, 204.0 kg of temperature-resistant and salt-resistant monomer M3, and 3,853.2 kg of deionized water into the batching kettle. While stirring, use frozen brine to control the solution temperature at 0°C, and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com