Colloidal microsphere ink for coloring textile digital printing structure and application of colloidal microsphere ink

A technology of colloidal microspheres and structural coloring, applied in textiles and papermaking, applications, inks, etc., can solve the problems of material waste, long assembly time, inability to position, assemble and color as required, and achieve quantitative controllable materials and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

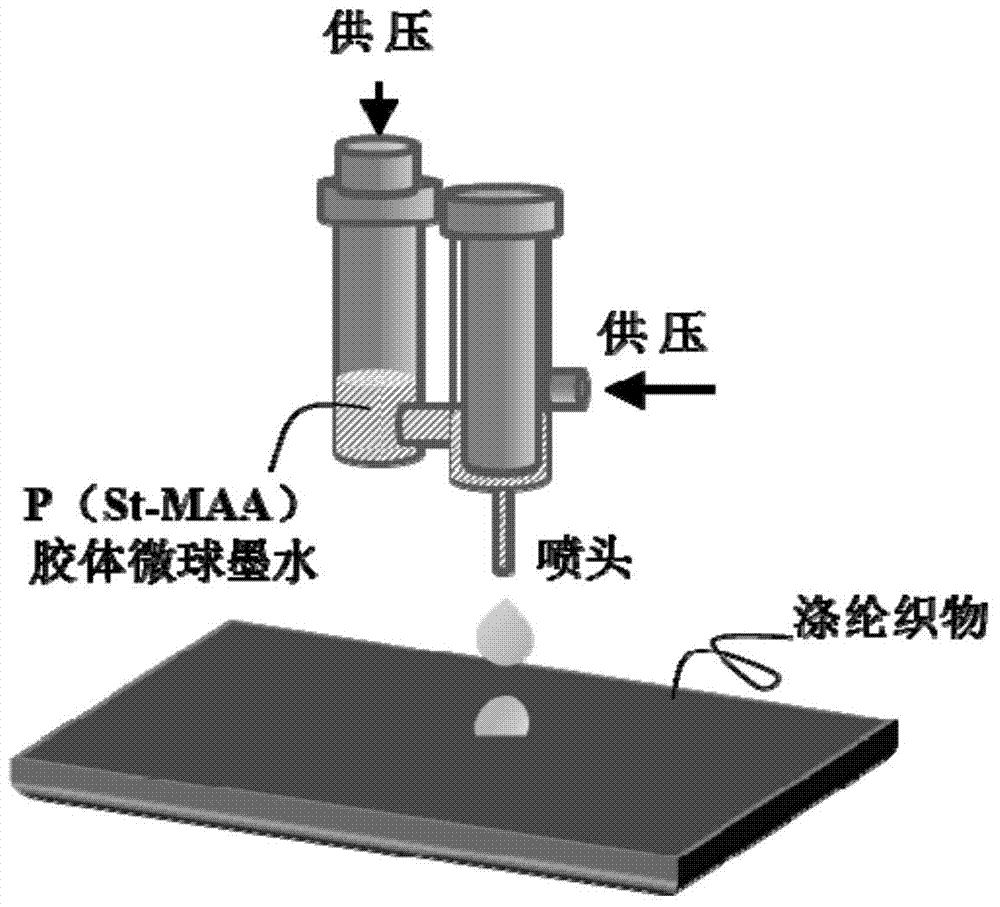

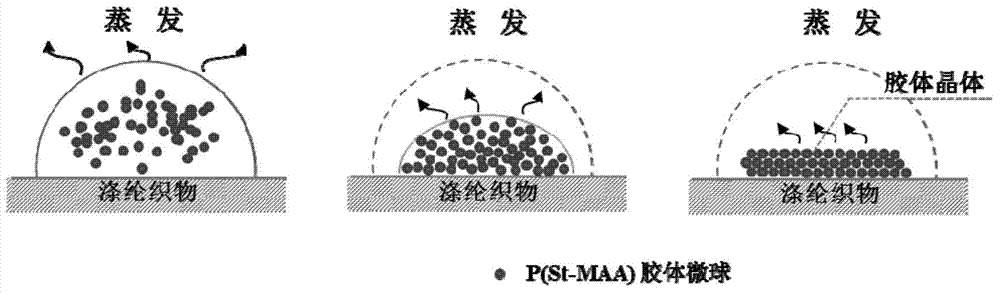

Method used

Image

Examples

Embodiment 1

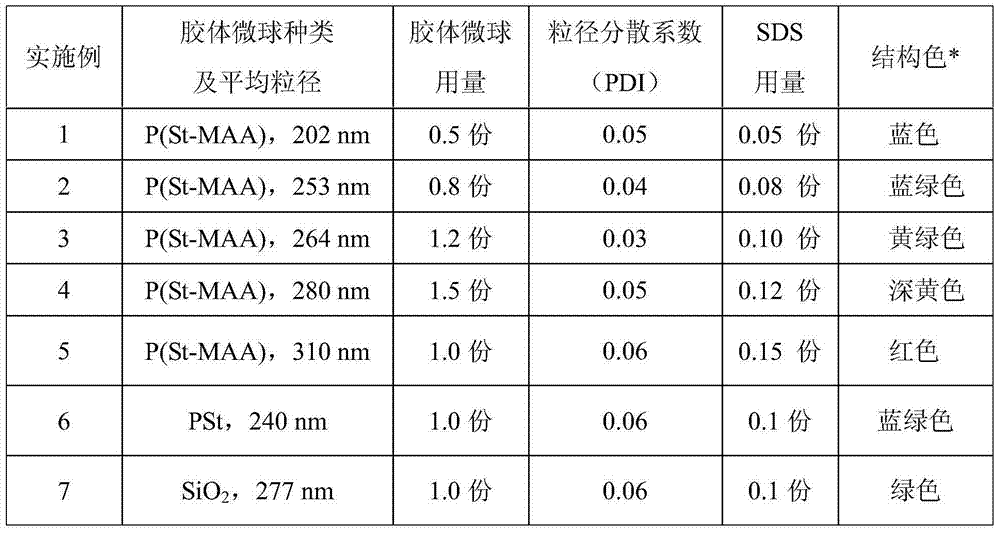

[0030] (1) Accurately weigh 0.5 part (based on solid content) of self-made P(St-MAA) colloidal microsphere emulsion (particle size: 202nm, dispersion coefficient: 0.05), add 0.05 part of anionic surfactant SDS, deionize 100 parts of water, then add sodium carbonate solution to adjust the pH of the system within the range of 7-8 (add while stirring), and then disperse in an ultrasonic disperser for 15 minutes to obtain uniformly dispersed colloidal microsphere ink;

[0031] Note: For the preparation method of P(St-MAA) colloidal microspheres, please refer to the reference - Zhu Wen, Huang Fangting, Zhang Ming, Zhou Jian, Preparation and Characterization of Styrene / Methacrylic Acid Copolymer Microspheres, "Functional Materials" , 2012, 43(11): 1418-1424. The specific method is: prepared by soap-free emulsion polymerization, the monomers are styrene (St) and methacrylic acid (MAA); the initiator is potassium persulfate (KPS), and the mass ratio of the feed is: m (St): m(MAA):m(H...

Embodiment 2

[0036] Accurately weigh 0.8 parts of self-made P(St-MAA) colloidal microsphere emulsion (particle size: 253nm, dispersion coefficient: 0.04) (based on solid content), add 0.08 parts of anionic surfactant SDS, and 100 parts of deionized water , then add sodium carbonate solution to adjust the pH = 7-8 (add while stirring), and then disperse in an ultrasonic disperser for 15 minutes to obtain uniformly dispersed colloidal microsphere ink;

[0037] The conditions and methods of jet printing and self-assembly are the same as in Example 1.

Embodiment 3

[0039] Accurately weigh 1.2 parts (based on solid content) of homemade P(St-MAA) colloidal microsphere emulsion (particle size: 264nm, dispersion coefficient: 0.03), add 0.10 parts of anionic surfactant SDS, and 100 parts of deionized water , then add sodium carbonate solution to adjust the pH = 7-8 (add while stirring), and then disperse in an ultrasonic disperser for 15 minutes to obtain uniformly dispersed colloidal microsphere ink;

[0040] The conditions and methods of jet printing and self-assembly are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com