Multi-cyclic huff-and-puff late production method for thin heavy oil reservoirs

A technology for heavy oil reservoirs and production methods, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve problems such as pressure reduction and energy reduction, and achieve the reduction of crude oil viscosity, prolongation of cycle production time, and improvement of Effects of steam sweep coefficient and thermal efficiency and displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

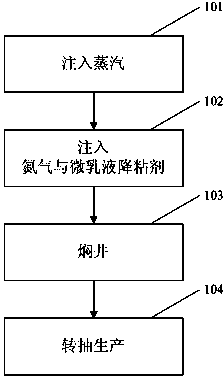

[0018] Such as figure 1 as shown, figure 1 It is a flow chart of the multi-round huff and puff post-exploitation method of the thin-layer heavy oil reservoir of the present invention. Before applying the multi-round huff and puff post-exploitation method of the thin-bed heavy oil reservoir of the present invention, a rough screening should be carried out according to the geological characteristics and development status of the heavy oil reservoir, and the reservoir meets the following conditions: the buried depth of the reservoir is ≤ 1400m , effective oil layer thickness ≤ 6.0m, permeability ≥ 300×10 -3 μm 2 , crude oil viscosity ≤ 20000mPa.s under reservoir conditions, without the influence of bottom water. Reservoir inclination angle ≤ 5°....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com