Storage capacitor, pixel unit and method for manufacturing storage capacitor

A technology for storing capacitors and pixel units, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as unstable display characteristics of the display panel, affecting the display characteristics of the display panel, and reducing the aperture ratio of the liquid crystal panel, so as to avoid Effects of releasing electrons, maintaining display characteristics, and reducing gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] see Figure 1 to Figure 6 , a method for manufacturing a storage capacitor provided in the first embodiment of the present invention, comprising the following steps:

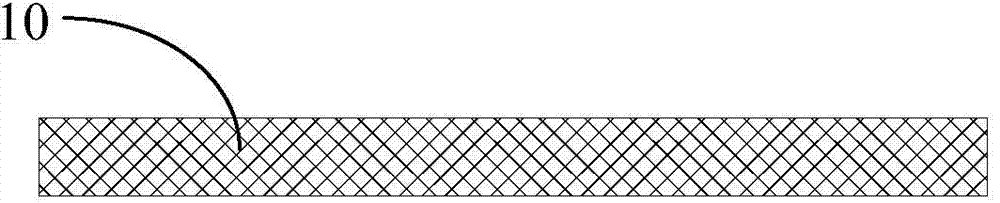

[0022] For a first step, see figure 1 , providing a substrate 10 made of glass or plastic. In this embodiment, the substrate 10 is made of glass.

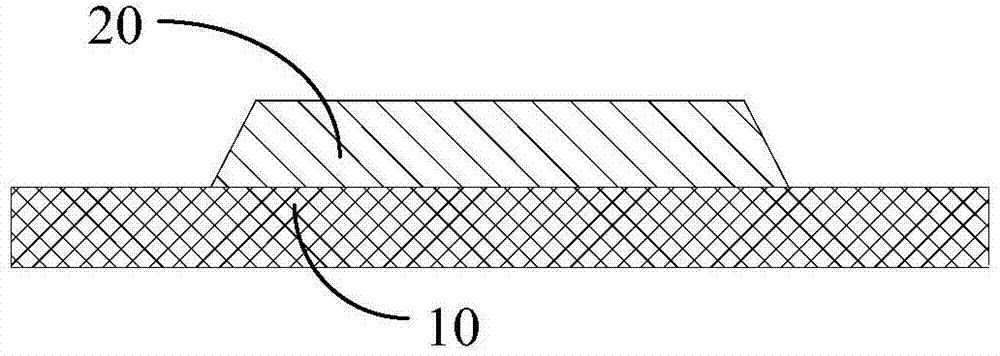

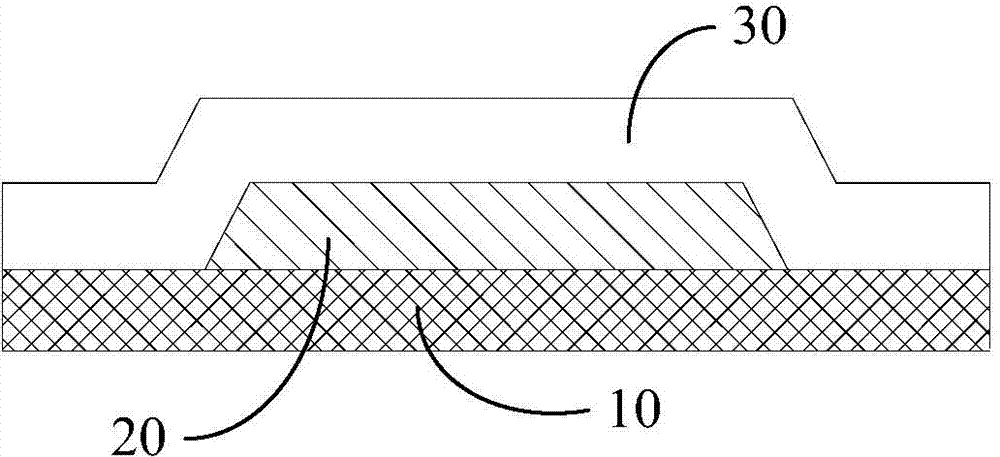

[0023] In the second step, see figure 2 , forming a first metal layer on the substrate 10 , and patterning the first metal layer to form a first electrode 20 . Wherein, the first metal layer is a molybdenum layer, an aluminum layer, a titanium layer or a copper layer, or a stack of any two layers, and the first metal layer is formed on the substrate 10 by a sputtering process, and patterned The first metal layer is used to form the first electrode 20 using a photomask process.

[0024] Wherein, the photomask manufacturing process includes steps such as exposure, development, and etching. Specifically, firstly, a layer of photo-resist (photo-resistance) ...

Embodiment 2

[0030] see Image 6 The storage capacitor 100 provided by the second embodiment of the present invention includes a substrate 10, a first electrode 20 formed on the substrate 10 and formed of a first metal layer, a first electrode 20 formed on the substrate 10 and the first electrode 20 An insulating layer 30, a semiconductor layer 40 formed on the first insulating layer 30, a second metal layer 50 formed on the semiconductor layer 40, formed on the first insulating layer 30, the semiconductor layer 40 and the second The second insulating layer 60 on the metal layer 50 and the pixel electrode 70 formed on the second insulating layer 60 and the second metal layer 50 as a second electrode.

[0031]The base 10 is made of glass or plastic. In this embodiment, the substrate 10 is made of glass. The first electrode 20 is a molybdenum layer, an aluminum layer, a titanium layer or a copper layer, or a stack of any two layers. The first insulating layer 30 is generally a SiNx layer....

Embodiment 3

[0034] See Figure 7 The pixel unit 200 provided by the third embodiment of the present invention is jointly defined by two adjacent scan lines 202 and two adjacent data lines 204 . The pixel unit 200 includes a thin film transistor 206 and a storage capacitor 100 as in the first embodiment. Wherein, the gate of the TFT 206 is electrically connected to the scan line 202 , the source is electrically connected to the data line 204 , and the drain is electrically connected to the pixel electrode 70 in the storage capacitor 100 . The scan line 202 provides a scan voltage to the thin film transistor 206 to turn on the thin film transistor 206 . The data line 204 provides the data voltage for the TFT 206, so that the pixel electrode 70 displays a gray scale corresponding to the data voltage, and the storage capacitor 100 stores the display voltage of the pixel electrode 70 during the off period of the TFT 206, that is, in Before the data is updated, the voltage of the pixel electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com