Continuous-phase spongy graphene material as well as preparation method thereof

A graphene and sponge-like technology, applied in the deposition of continuous-phase sponge-like graphene materials based on the surface of foamed nickel and its preparation, in the field of graphene materials, can solve problems such as the inability to achieve the nature of graphene, and achieve good cycle stability, contact The effect of enlarged surface and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in combination with specific embodiments.

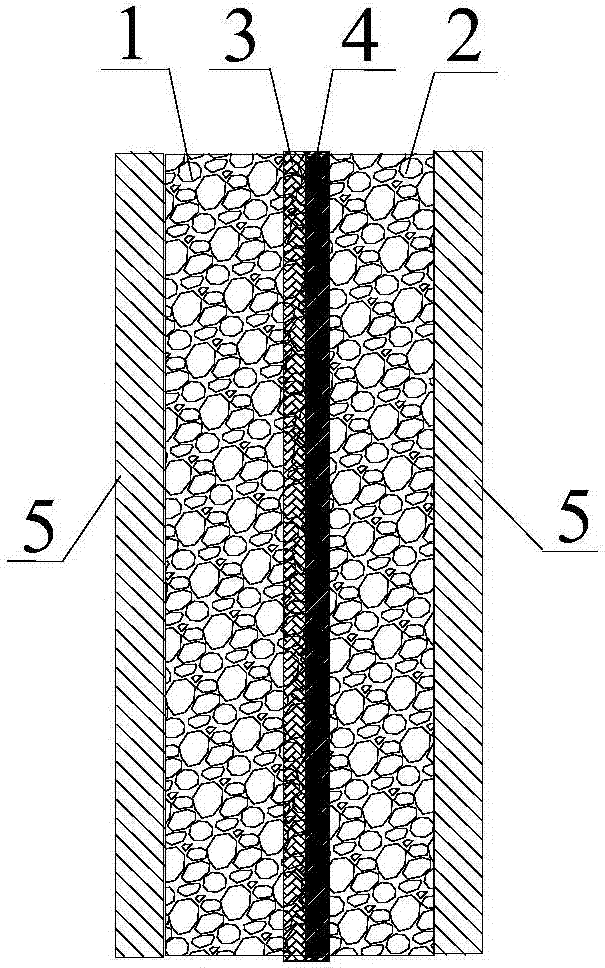

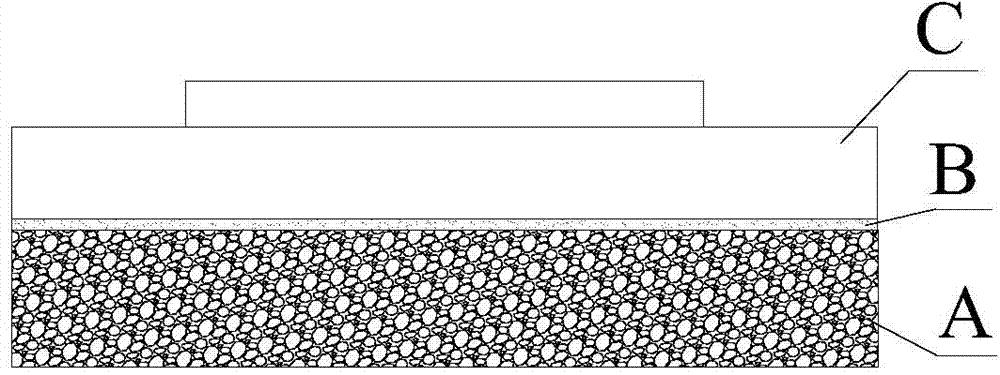

[0032] A continuous phase sponge-like graphene material, the core of the material is a foamed nickel substrate, and the surface of the foamed nickel substrate is coated with CH by CVD vapor phase deposition. 4 The graphene obtained by gas, the graphene material is a piece of continuous phase sponge graphene.

[0033] The foamed nickel substrate at the core of the continuous phase spongy graphene material of the present invention may also be a foamed copper-nickel substrate, and its function, performance and effect are the same as those of the foamed nickel substrate.

[0034] The preparation method of continuous phase spongy graphene material of the present invention, is made up of the following steps;

[0035] Step 1: Cut the nickel foam substrate according to the required size;

[0036] Step 2, sealing the two ends of the nickel foam substrate by spraying or pasting; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com